A dependable supplier is a must when selecting analytical equipment to support high-quality production. This dependability is crucial in terms of being able to offer reliable equipment and experts who can address queries and collaborate to ensure the use of appropriate techniques for the required goals.

Image Credit: ShutterStock/Mykolastock

Hitachi has worked closely with customers for their materials analysis needs across various industries for over half a century, developing customized testing methods for numerous industrial applications.

Hitachi’s application and product experts are always on hand to support its clients in addressing their analysis challenges.

Recently, a customer in the polymers industry approached Hitachi, seeking support on which recycled plastic should be introduced into their production line. The company essentially wanted to make sure that they were using the appropriate raw material.

Hitachi directed this query to Olivier Savard, its thermal analysis product manager, who was happy to explain some of the techniques and instruments that would be best suited to working with recycled plastic and maintaining high quality standards.

Olivier, on behalf of Hitachi, provides a brief response to this question in the video below, introducing some of Hitachi’s instruments that aid in qualifying materials and determining levels of contaminants and additives.

Using Differential Scanning Calorimetry (DSC) to Confirm You Have the Right Type of Polymer

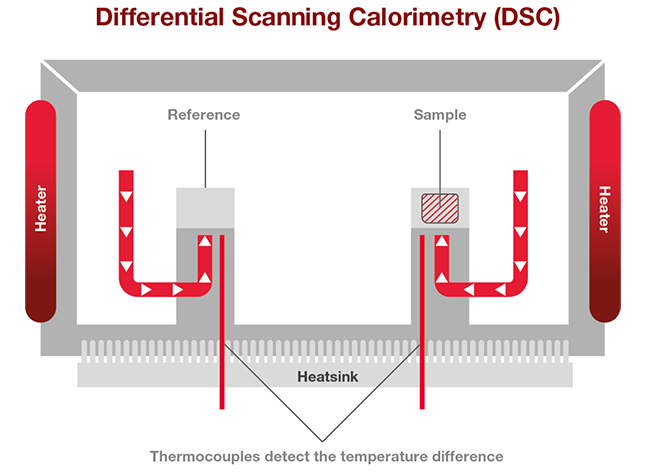

A differential scanning calorimeter (DSC) is an essential tool for confirming the type of polymer and its potential mixture with others, such as polyethylene (PE) and polypropylene (PP).

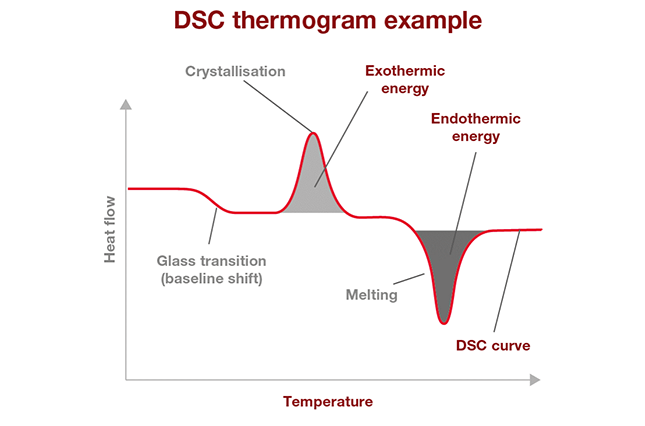

Polymers, like other materials, exhibit different thermal properties when heated or cooled. Some polymers have a single melting point, while others also feature a glass transition or re-crystallization point. These traits are specific to each polymer, depending on factors like type, synthesis, and additives.

Accurately measuring the temperature and energy required for these thermal transitions is a practical way to verify their identity. A DSC does precisely this task.

By heating a known amount of polymer at a specific heating rate (typically 10 °C/minute) and comparing its temperature to an inert reference (usually an empty aluminum pan), a DSC accurately and precisely detects thermal transitions within a polymer.

Once these transitions are found, a user can easily compare the results with expectations. For example, one can check if the melting temperature of a new polymer batch matches the reference.

The DSC confirms accuracy and detects contamination by another polymer (e.g., identifying PP contamination in a PE sample).

Image Credit: Hitachi High-Tech Analytical Science Ltd

Image Credit: Hitachi High-Tech Analytical Science Ltd

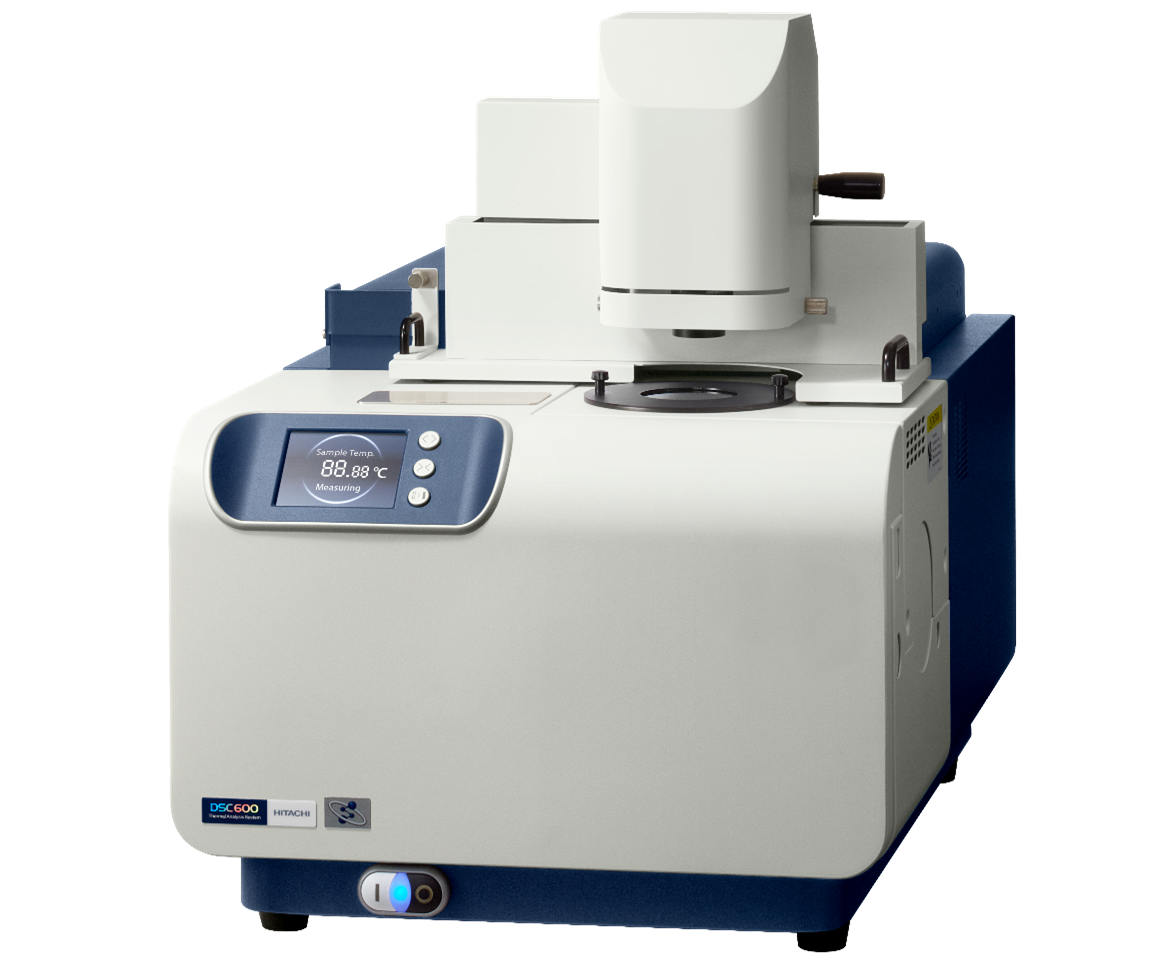

Hitachi’s NEXTA DSC instruments are designed for precise testing and material characterization based on thermal properties like melting points, crystallization, and glass transitions.

When developing new materials, the NEXTA DSC600 is the instrument of choice thanks to its high sensitivity and resolution, which allows users to achieve a better understanding of their material. The NEXTA DSC200 is favored for routine testing in a wide variety of applications.

Both instruments work with Hitachi’s Real View® camera system, allowing real-time visualization of polymer behavior and enhancing material comprehension.

NEXTA DSC thermal analyzer. Image Credit: Hitachi High-Tech Analytical Science Ltd

Using Thermogravimetric Analysis (TGA) to Judge the Levels of Additives in the Polymers

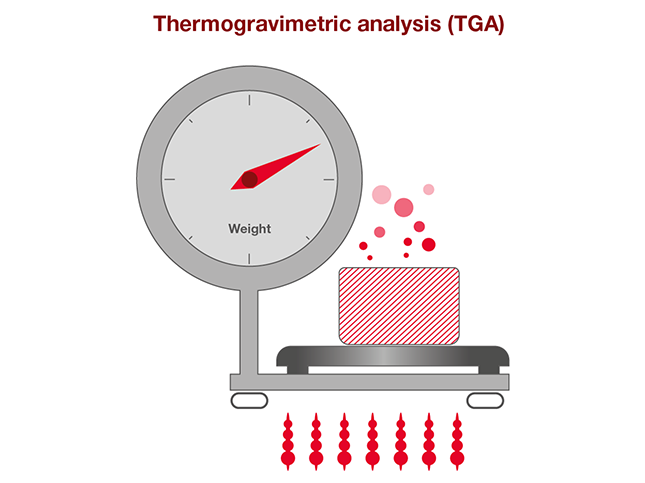

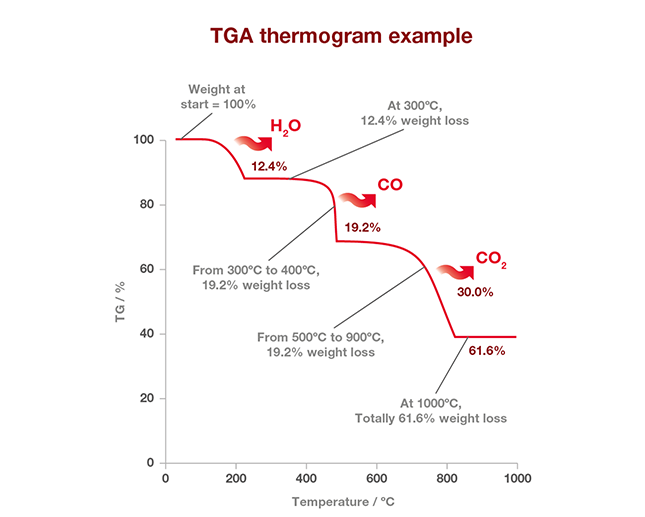

Thermogravimetry (TGA) offers compositional analysis, making it a widely-used technique to assess polymer purity and the presence of additives like plasticizers, pigments - such as carbon black or titanium dioxide (TiO2) - and inorganic components in materials.

It also provides insights into the quantities of UV stabilizers and antioxidants. Different polymer types and their additives have distinct evaporation or decomposition temperatures.

During these transitions, the polymer proportionately loses weight based on the sample’s composition, enabling precise quantification of each constituent. TGA accomplishes the quantification of weight losses and, consequently, the amount of each ingredient in a material.

By subjecting a known polymer quantity to a specific heating rate (usually 10 °C/minute) under a controlled atmosphere (nitrogen or air), TGA effectively controls temperature and measures weight loss. Unique degradation patterns in various materials allow TGA to accurately assess ingredient quantities within the polymer.

For instance, in a rubber filled with oil extender and carbon black, TGA quantifies each ingredient. The oil is released first, followed by the rubber under an inert atmosphere. Transitioning from an inert (nitrogen) to a combustive (air) atmosphere enables the combustion of carbon black, facilitating its quantification.

However, TGA encounters challenges when quantifying inorganic materials like calcium carbonate or titanium dioxide, as these lack weight loss characteristics. Non-combustible ingredients can be measured, but they encompass materials retaining weight throughout the experiment.

These non-combusting materials are often called ash content. To quantify materials within the ash content, alternative techniques like X-Ray fluorescence (XRF) are employed.

Image Credit: Hitachi High-Tech Analytical Science Ltd

Image Credit: Hitachi High-Tech Analytical Science Ltd

Hitachi’s NEXTA STA instruments concurrently merge DSC and TGA measurements, providing a comprehensive view of materials and potential contaminants.

Similar to Hitachi’s NEXTA DSC, the NEXTA STA instruments seamlessly integrate with the Real View® camera system. This integration allows real-time observation of polymer behavior during heating and cooling. The accompanying images, combined with the results, offer an enhanced understanding of the studied materials.

NEXTA STA200RV thermal analyzer. Image Credit: Hitachi High-Tech Analytical Science Ltd

Identifying and Quantifying Inorganic Fillers and Other Additives in Recycled Polymers Using XRF Analysis

XRF analysis can assist in understanding various facets of the materials being worked with, such as quantifying the presence of titanium dioxide in the material.

This technique, recognized for its speed and accuracy, is utilized to determine the elemental composition of the materials in question. The outcomes are swiftly displayed on the screen within seconds.

Employing a non-destructive method, this approach enables operators to monitor the levels of catalyst residue in virgin polymers throughout the polymerization process. XRF also can measure the quantities of additives, including antioxidants, antistatic agents, flame retardants, lubricants, stabilizers, pigments, and fillers.

Through XRF analyzers, users can assess a wide range of materials, including solids, liquids, powders, pastes, films, and pellets, making them highly suitable for polymer analysis. The XRF instrument promptly reveals results, providing comprehensive insights into the precise composition of the material at hand.

Hitachi’s XRF analyzers include the handheld X-MET8000, along with the benchtop LAB-X5000 and X-Supreme8000 analyzers.

These products have been engineered to deliver swift, dependable results, ensuring ease of use and seamless integration into operations. They are built with durability in mind and can withstand even some of the most demanding production environments.

Image Credit: Hitachi High-Tech Analytical Science Ltd

Image Credit: Hitachi High-Tech Analytical Science Ltd

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.