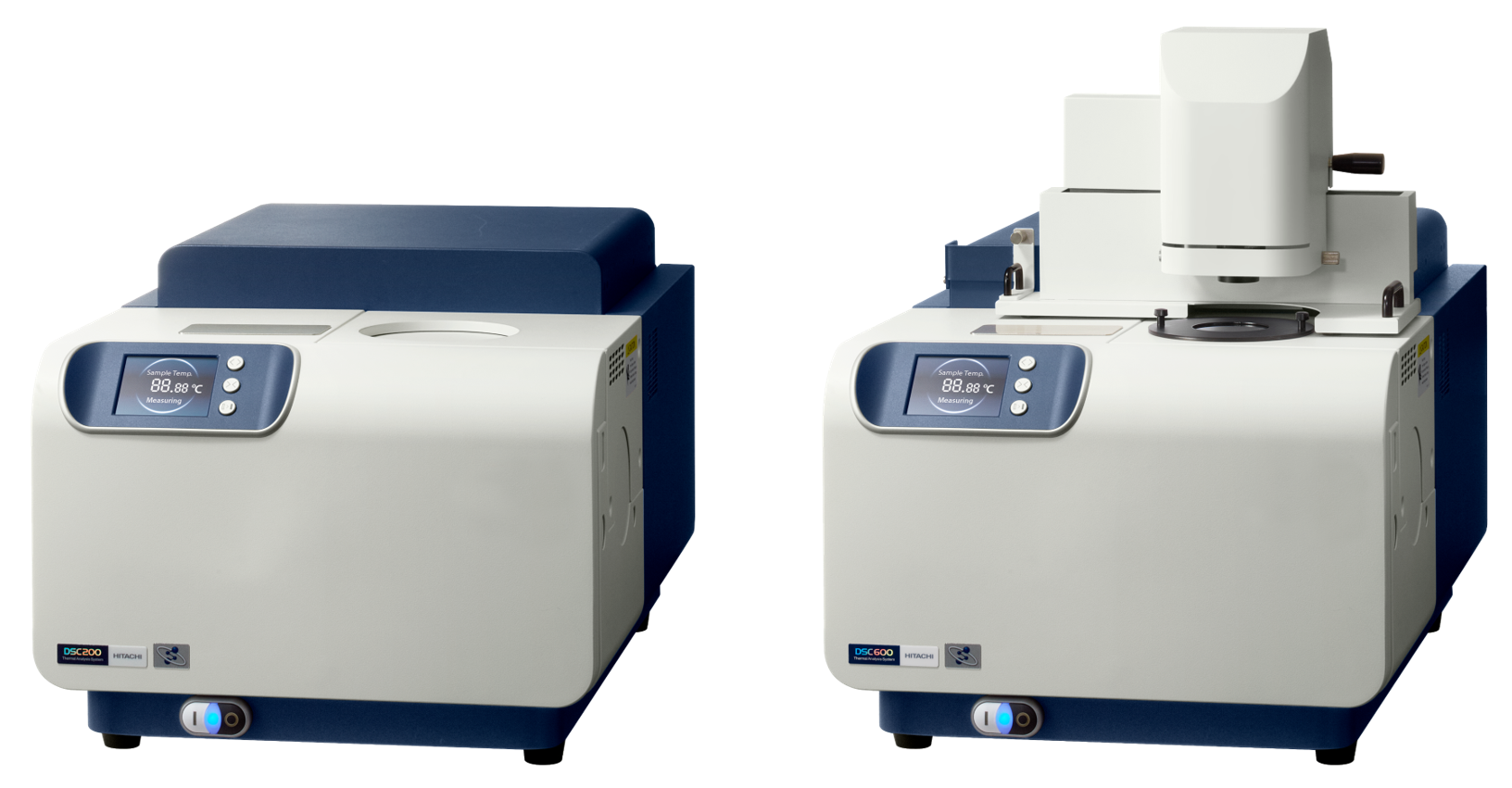

Our DSC series includes the NEXTA DSC200, which covers a wide variety of routine applications, to our NEXTA DSC600, which is purpose designed to meet the most advanced DSC applications, particularly within applied research.

Our DSC (differential scanning calorimeters) are widely used for material characterization; eg melting point, glass transition, crystallization. The NEXTA DSC Series is used both in quality control and R&D across a wide range of industries, including polymers, pharma, chemical, oil and gas, food and metals. Hitachi’s DSC offers world-class sensitivity and baseline flatness, which gives more accurate testing and the ability to evaluate even the smallest of reactions.

We offer a range of solutions, from NEXTA DSC200, which covers a wide variety of applications, to our NEXTA DSC600, which is purpose designed to meet the most advanced DSC applications, particularly within applied research.

Features

- High sensitivity with superior sensor technology

- World-class baseline performance with unique furnace design

- Real View®; camera system which shows you material behaviour live on screen

- Polarized Micro Sample Observation unit with high-resolution imaging for crystal orientation, multilayer film quality control, fish-eye contamination detection, and failure analysis.

- Flexibility to add options post-installation

- Superior software, intuitive for ease of use, but allowing more advanced functionality where needed

- Reliable auto sampler testing, and faster operation with auto analysis function

Benefits

- Intuitive software and auto sampler make the analyzer easy to use and time efficient

- Cost efficiency with a reliable and robust system

- Increased accuracy thanks for the ability to evaluate the smallest of reactions

- Easy report creation, even for non-expert users, thanks to the unique camera system

Image Credit: Hitachi High-Tech Analytical Science