Composite materials have revolutionized various industries, from aerospace to automotive, by offering lightweight, high-strength alternatives to traditional materials. However, characterizing and understanding their complex molecular structure presents challenges. This is where Raman spectroscopy can provide valuable insights.

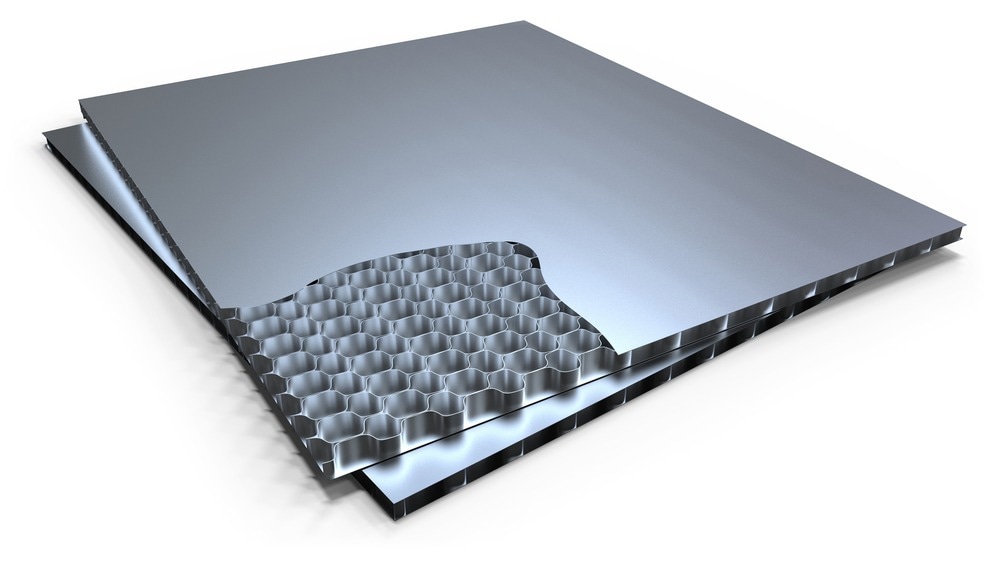

Image Credit: Peter Sobolev/Shutterstock.com

Why Is It Important to Analyze Composites?

Analyzing composite materials is of paramount importance across industries and applications. It is a critical component in the entire product lifecycle, from initial research to end-of-life assessment.

Analytical testing validates theoretical models and assumptions during the design phase, ensuring the composite's expected performance. It also allows researchers and engineers to optimize composite performance by understanding how individual constituents interact and influence overall behavior. This facilitates material selection and manufacturing process refinements, enhancing durability, reliability and suitability for critical applications.

This rigorous analysis guarantees adherence to standards, optimizing composite performance, enhancing durability, and ensuring reliability, especially in critical applications like aerospace and construction. Additionally, it impacts safety, sustainability, cost-efficiency, environmental assessment, and material science innovation.

How Raman Spectroscopy Is Used to Analyze Composite Materials?

Raman Spectroscopy is a non-invasive analytical method that offers comprehensive insights into composite materials by providing detailed information about their chemical structure, phase composition, crystallinity, and molecular interactions. It operates on the principle of illuminating the material with laser light, causing molecules within it to scatter light in distinct patterns.

In Raman spectroscopy, a high-intensity laser generates intense light for detecting Raman signals. The laser's wavelength is crucial, as shorter wavelengths produce stronger Raman signals but may induce autofluorescence, complicating the analysis. The system's optics are responsible for directing and collecting the scattered Raman emissions, often employing long-pass filters to separate the laser light from the Raman signals.

The Raman spectrometer captures and analyzes the transmitted light, producing a spectrum that showcases the Raman shift relative to the laser frequency. This spectrum is a rich source of information, with each peak corresponding to a specific molecular bond vibration, offering insights into individual bonds and molecular groups.

Raman spectroscopy is a valuable tool for analyzing composite materials due to its speed, non-destructiveness, high spatial resolution, versatility across material systems, capacity to provide molecular insights, in-situ monitoring capabilities, complementary role in conjunction with other techniques, and insensitivity to water, making it suitable for various applications and environmental conditions.

What Insights Does Raman Spectroscopy Offer in the Analysis of Composite Materials?

Raman spectroscopy enables the identification of a composite's chemical structure and identity through its unique Raman spectrum, allowing for swift material differentiation. This technique also sheds light on the presence of various phases and polymorphs within a composite, aiding in understanding its complex structure.

Raman spectroscopy can assess intrinsic stress and strain in materials, making it essential for studying how composites behave under manufacturing conditions and loads. It is highly effective at detecting contamination and impurities, ensuring the quality and purity of composite products.

Furthermore, when combined with mapping or imaging systems, Raman spectroscopy can generate images that reveal the distribution of chemical components, phases, and crystallinity variations within composites.

In ceramic composites, Raman spectroscopy effectively characterizes reinforcement structures, including materials like carbon and boron nitride fibers within ceramic matrices, and helps study phase transformations at high temperatures.

Lastly, it can detect damage within composites by monitoring changes in the Raman spectrum that indicate defect formation, facilitating in-situ damage analysis.

Understanding Graphene's Role in Reinforcing Polymer Composites through Raman Spectroscopy

When graphene-based polymer composites undergo deformation, internal stress is generated and transferred from the polymer matrix to the monolayer graphene. Raman spectroscopy allows us to characterize both graphene and its deformations.

One significant application of Raman spectroscopy in this context is assessing the level of reinforcement in polymer nanocomposites with graphene flakes of varying layer numbers. When stress is applied, the positions of Raman bands in the graphene spectra shift, providing insights into the material's stress and, consequently, its effective Young's modulus.

Raman mapping has also been employed to investigate strain distribution in graphene flakes within these composites and to assess stress transfer from the polymer matrix. This mapping technique enables precise monitoring of reinforcement levels and strain distribution in graphene-containing specimens, providing valuable insights into their mechanical properties.

Exploring Hybrid Nanocomposites with Raman Spectra

Researchers have used Raman spectroscopy to explore hybrid nanocomposites formed by single-walled carbon nanotubes (SWCNTs) and polyaniline (PANI). This one-step in situ polymerization process leads to the development of highly organized chain structures within the composite.

Raman spectroscopy serves to validate the orderly packing of PANIs, offering tangible evidence of the polymerization process. Additionally, it provides a glimpse into the chemical transformations occurring within the composite due to the interactions between PANI and SWCNTs.

Moreover, Raman spectroscopy can evaluate the degree of functionalization of CNTs in these composites. By scrutinizing Raman spectra, researchers can monitor shifts in the relative intensities of specific bands, such as the D band, an indicator of defects or structural changes within the nanotubes. This valuable information aids in assessing the extent of CNT functionalization and its consequences for the composite's properties.

Raman Spectroscopy Unveils Electrolyte Decomposition in Cathode Composites of All-Solid-State Lithium-Sulfur Batteries (ASSLSB)

In a study published in the Chemistry of Materials, the researchers used Raman spectroscopy to analyze the cathode composite after 20 cycles and identified a peak derived from a S-S bond, which provided insights into the formation of thiophosphates with long-chain cross-linked sulfur during the charging and discharging cycles.

This information is crucial for understanding the decomposition behavior of the electrolytes in ASSLSBs and how it impacts battery performance.

How Raman Spectroscopy Can Be Used More Widely by The Industry for Research and Development

There are significant opportunities to expand the use of Raman spectroscopy for composites by making the technique more accessible and valuable in industrial settings.

Portable Raman systems for real-time quality control during manufacturing could transform defect identification and process monitoring. Developing rugged, handheld spectrometers would also enable more field-based analysis to increase adoption. Ongoing advances in instrumentation like hyperspectral imaging will permit faster, higher-quality data collection to inform R&D.

Collaborative efforts between industry and academia will facilitate the transfer of emerging techniques from laboratories to production facilities. Establishing extensive databases containing reference Raman spectra simplifies composite screening and analysis, enhancing efficiency. Most crucially, comprehensive personnel training in Raman spectroscopy applications would drive more widespread implementation across sectors.

With coordinated efforts to refine, standardize, and share best practices, Raman could become an essential tool for enabling next-generation composite advancement.

More from AZoM: Raman Spectroscopy for Glass and Ceramic Analysis

References and Further Reading

HORIBA. (2023). What is Raman Spectroscopy? [Online]. Available at: https://www.horiba.com/int/scientific/technologies/raman-imaging-and-spectroscopy/raman-spectroscopy/

Runka, T. (2017). Spectroscopic properties of polymer composites. Physical Sciences Reviews, 2(8), 20170025. https://doi.org/10.1515/psr-2017-0025

Gamo, H., Hikima, K., & Matsuda, A. (2022). Understanding Decomposition of Electrolytes in All-Solid-State Lithium–Sulfur Batteries. Chemistry of Materials, 34(24), 10952-10963. https://doi.org/10.1021/acs.chemmater.2c02926

Li, Z., Deng, L., Kinloch, I. A., & Young, R. J. (2023). Raman spectroscopy of carbon materials and their composites: Graphene, nanotubes and fibres. Progress in Materials Science, 101089. https://doi.org/10.1016/j.pmatsci.2023.101089

Wagner, H. D. (2011). Raman spectroscopy of polymer–carbon nanotube composites. In Polymer–Carbon Nanotube Composites (pp. 400-427). Woodhead Publishing. https://doi.org/10.1533/9780857091390.2.400

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.