Milk powders developed by spray drying are used in the food industry, finding applications in various products, including confectionery, baked goods, soups, sauces, and beverages. They are also directly supplied to end consumers.

Image Credit: Freeman Technology

The flow characteristics of these powders determine their usefulness and impact their overall value, particularly in efficient and effective food processing.

Powders that move smoothly through the production chain enhance industrial productivity, reducing unplanned interruptions and inefficiencies that can impact profitability.

Understanding the production of milk powders with optimal flow properties is advantageous. While lipid content is a significant factor, other elements like moisture content and particle size also define flow behavior.

The researchers at the Universite de Lorraine in Nancy, France, delved into this aspect in their study. They explored the flowability of spray-dried milk powders concerning the composition of the feed concentrate and an aeration pre-treatment.1

Spray-dried powders with varying lipid content (1.5%, 14%, and 26%) were generated from skimmed, semi-skimmed, and whole milk concentrates, respectively, prepared by reconstituting skimmed and whole milk powders.

To compare, aerated counterparts were produced by whipping samples of each concentrate before spray drying under strictly comparable conditions. Using the FT4 Powder Rheometer®, dynamic and shear flow properties were measured for all six spray-dried milk powders.

These results show meaningful correlations between feed concentrate properties and process-relevant flow properties.

Flowability

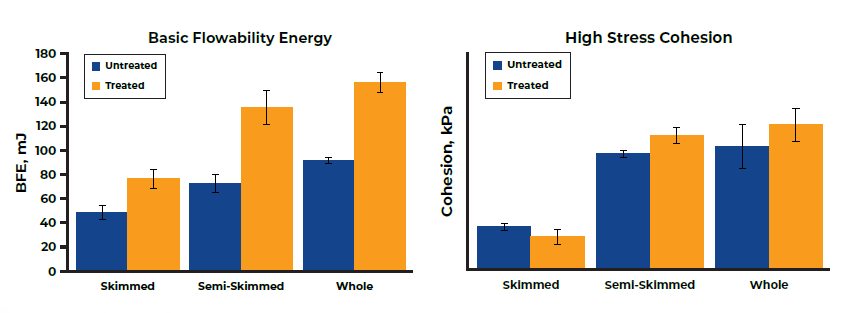

Basic Flowability Energy (BFE) values gauge a powder's tendency to flow under confined or forcing conditions, particularly in a low to moderately stressed state.

These values have a secure connection with blending performance and the flow within the feed frame of a dosing system or tableting press, making them pertinent to food processing operations.

BFE values are highly discriminative, often detecting even subtle differences in samples that other flow properties categorize as identical or closely similar.

In the case of these milk powders, it was observed that BFE increased with lipid content (skimmed 1.5%, semi-skimmed 14%, whole 26%) for untreated samples and those prepared from treated/aerated concentrates. These findings highlight the strong influence of aeration on BFE, leading to increased resistance to flow.

Image Credit: Freeman Technology

Shear properties, such as cohesion, quantify the behavior of consolidated powders under relatively high stress and are relevant to hopper discharge performance.

These results present a distinct perspective on the samples, revealing minimal differentiation between the semi-skimmed and whole milk powders but notably less cohesion in the skimmed sample. Aeration had only a marginal effect on sample behavior for all three samples under high-stress conditions.

Physicochemical properties measured for the milk powders also shed light on these observed trends.

For instance, semi-skimmed and whole milk powders exhibited high and over-representative surface lipid content. The increased surface "stickiness" due to lipid distribution explains the high cohesion and resistance to flow observed in the semi-skimmed and whole milk powders, relative to skimmed.

The more pronounced effect under high-stress conditions may result from free fat release at the powder surface under a consolidating load.

Aeration leads to a more uniform lipid dispersion but concurrently results in narrower particle size distributions centered on finer particle size.

This latter trend potentially affects particle packing, a crucial aspect concerning BFE values, and may help elucidate the observed trends in flow behavior under low-stress conditions. High consolidation potentially masks the differences induced by pretreatment.

Importantly, these observed trends provide insight into how various milk powders will behave in the processing.

Low lipid content promotes low cohesion and good flowability in hoppers and silos, and more broadly, processors aiming to aerate dairy concentrates to enhance characteristics such as wettability and solubility should be cautious about the potential simultaneous compromise of flowability and, by extension, processability.

Conclusion

The findings outlined in this article highlight the significance of assessing dynamic and shear powder properties for acquiring a process-relevant understanding of diverse milk powders and the influence of concentrate pretreatment.

Employing this multivariate analysis offers a level of detail that simple, single-parameter powder testing methods cannot provide, proving to be highly effective in aiding the formulation of optimal ingredients for food processing.

References and Further Reading

- T. Fournaise, J. Burgain, C. Perroud, J. Scher, G. Gaiani, J. Petit ‘Impact of formulation on reconstitution and flowability of spray-dried milk powders’ Powder Technology 372 (2020) 107-116.

This information has been sourced, reviewed and adapted from materials provided by Freeman Technology.

For more information on this source, please visit Freeman Technology.