By Taha KhanReviewed by Lexie CornerSep 11 2024

By Taha KhanReviewed by Lexie CornerSep 11 2024

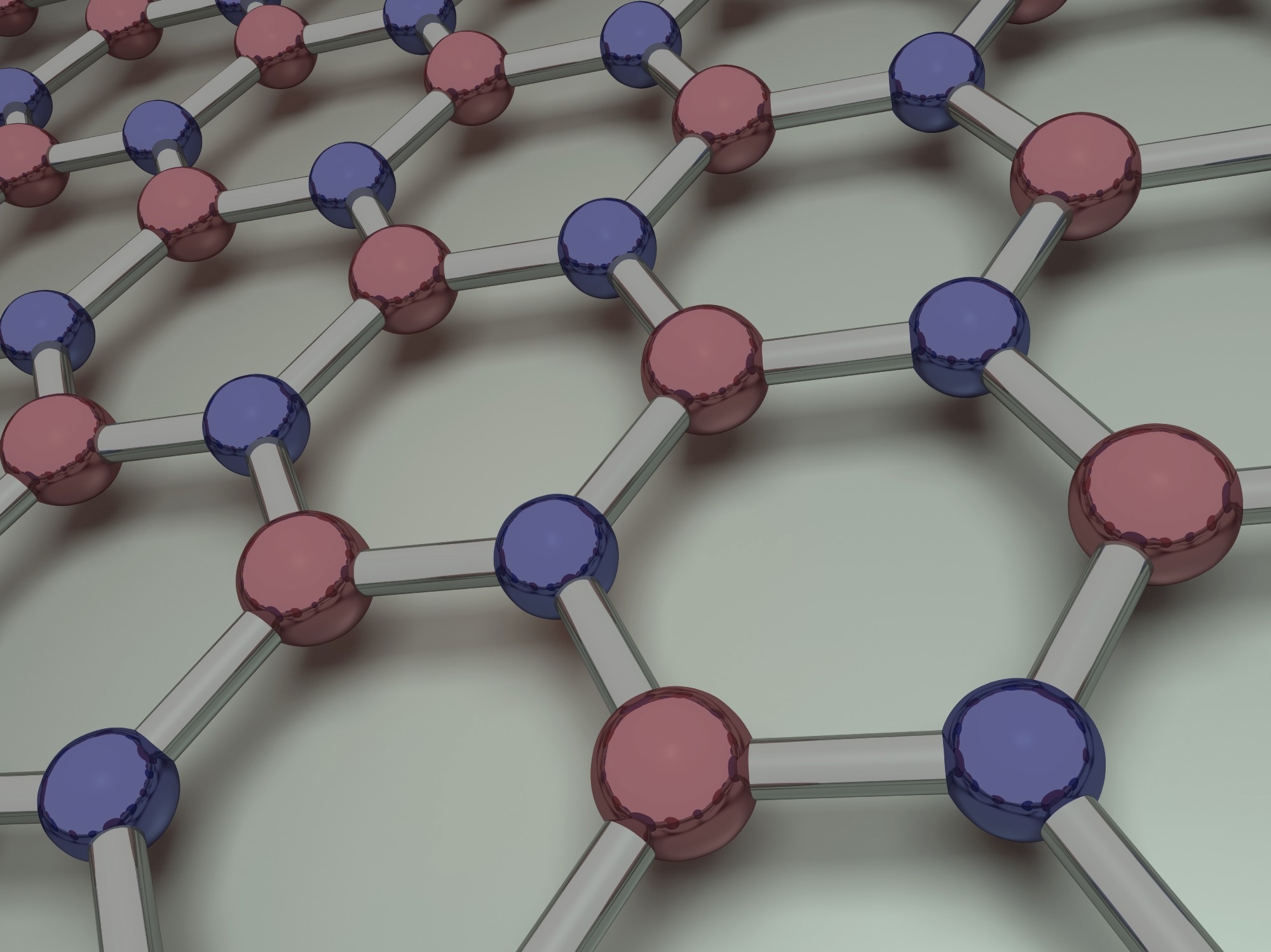

Boron nitride (BN), a compound of boron and nitrogen, is a ceramic material known for its unique properties, particularly in high-temperature applications. While boron nitride exists in several crystalline forms, hexagonal boron nitride (h-BN) is the most common. This article explores hot-pressed boron nitride, its thermal properties, and its practical applications.

Image Credit: ogwen/Shutterstock.com

Hot-Pressed Boron Nitride: Process and Performance

Hot pressing is a fabrication technique that applies heat and pressure simultaneously to densify ceramic materials.

BN hot pressing processing begins with the preparation of highly pure BN powder. This powder is placed into a mold and subjected to high temperatures and pressure, which eliminates voids and impurities. The result is a dense, porosity-free product.

This increased density maximizes thermal conductivity and stability, making hot-pressed boron nitride ideal for applications requiring effective thermal management.1-3 It efficiently conducts heat away from critical components, preventing overheating and ensuring the longevity and reliability of systems operating under high-temperature conditions.1, 4

Hot-pressed BN also maintains its structural integrity under prolonged exposure to high temperatures. This is due to strong covalent bonding within the BN structure, which resists decomposition under thermal stress.

In addition to its thermal stability, hot-pressed BN is chemically inert, making it ideal for use in harsh environments where both high temperatures and chemical exposure are significant concerns.1, 3, 5 Its heat resistance and ability to withstand thermal shock without melting make it a preferred material in industries where rapid temperature changes are expected.

Alumina is another ceramic material with good thermal properties, but its thermal conductivity is lower than that of hot-pressed BN.9 While graphite possesses excellent thermal conductivity, its susceptibility to oxidation and chemical attacks limits its usefulness in certain environments.10 This combination of properties makes hot-pressed BN a highly reliable material for demanding thermal conditions.

Enhancements in Boron Nitride Nanosheets (BNNS)

In a 2020 study, researchers investigated the thermal properties of hot-pressed BN nanosheets (BNNS), aiming to enhance their thermal conductivity and stability. The study describes how functionalizing BNNS with (3-aminopropyl)triethoxysilane (APTES) and incorporating them into an epoxy matrix significantly improved these key thermal properties.

The resulting hot-pressed composite films showed enhanced thermal conductivity and mechanical strength, making them ideal for high-power electronic device packaging applications.6

Industrial Applications of Hot-Pressed Boron Nitride

Hot-pressed BN's unique thermal and electrical insulating properties make it ideal for various industrial applications. In the electronics industry, hot-pressed BN is used in heat sinks and thermal management systems, where its ability to efficiently dissipate heat helps enhance the reliability and performance of high-powered electronic components.7

Similarly, in the aerospace sector, BN's lightweight nature, high thermal stability, and oxidation resistance make it suitable for components exposed to extreme temperatures. Its ability to endure harsh environments while maintaining structural integrity is crucial for aerospace applications.8

Advances in Heat Sink Applications for Hot-Pressed Boron Nitride

In a 2023 study, researchers explored the potential of h-BN composites for heatsink applications by developing polymer composites using phenolic resin and h-BN. Through hot compression molding and solution-based mixing, they achieved composites with high thermal conductivity (up to 18.5 Wm-1K-1) and excellent dielectric properties.

These attributes are crucial for creating lightweight and efficient heat sink materials in electronic devices. The study underscores the effectiveness of this approach in producing high-performance materials capable of dissipating heat efficiently, making them ideal for advanced heat sink applications.7

Discover More: What Role Does Boron Nitride Play in 3D Printing?

Conclusion

Thermal conductivity, thermal expansion, and stability are key factors that determine a material's suitability for specific applications. Understanding these properties is essential for selecting the right material for high-performance environments.

BN, with its high thermal conductivity and exceptional thermal stability, performs particularly well in high-temperature applications. These characteristics enable efficient heat dissipation, reducing the risk of thermal degradation and preserving material integrity.

As research and development continue, the potential for even more innovative applications of hot-pressed BN is expected to grow.

References and Further Reading

- Kusunose, T., Sekino, T. (2016). Thermal conductivity of hot-pressed hexagonal boron nitride. Scripta Materialia. https://doi.org/10.1016/j.scriptamat.2016.07.011

- Zhang, Z., et al. (2020). Microstructure evolution and grain growth mechanisms of h-BN ceramics during hot-pressing. Journal of the European Ceramic Society. https://doi.org/10.1016/j.jeurceramsoc.2020.02.011

- MasCera. (2022). What are difference between hot pressed boron nitride and pyrolytic boron nitride? [Online] MasCera. Available at: https://www.mascera-tec.com/news/what-are-difference-between-hot-pressed-boron-nitride-and-pyrolytic-boron-nitride (Accessed on 24 August 2024)

- Hung, CC., Hurst, J., Santiago, D., Lizcano, M., Kelly, M. (2017). Highly thermally conductive hexagonal boron nitride/alumina composite made from commercial hexagonal boron nitride. Journal of the American Ceramic Society. https://doi.org/10.1111/jace.14638

- Li, T., et al. (2024). Effect of hexagonal boron nitride content on the anisotropy of hot-press-sintered AlN/BN composite ceramics. Ceramics International. https://doi.org/10.1016/j.ceramint.2024.05.243

- Liu, Z., Li, J., Liu, X. (2020). Novel functionalized BN nanosheets/epoxy composites with advanced thermal conductivity and mechanical properties. ACS Applied Materials & Interfaces. https://pubs.acs.org/doi/abs/10.1021/acsami.9b21467

- Danilov, EA., Samoilov, VM., Kaplan, IM., Medvedeva, EV., Stepashkin, AA., Tcherdyntsev, VV. (2023). Excellent thermal and dielectric properties of hexagonal boron nitride/phenolic resin bulk composite material for heatsink applications. Journal of Composites Science. https://doi.org/10.3390/jcs7070291

- Montanari, GC., Shafiq, M., Myneni, SB., Lizcano, M., Williams, TS. (2024). Electrical Characterization of Boron Nitride-Filled Insulation for Aerospace and Avionics Applications. Energies. https://doi.org/10.3390/en17123016

- Chen, X., Wang, J., Zhang, C., Yang, W., Lin, J., Bian, X., He, S. (2021). Performance of silicone rubber composites using boron nitride to replace alumina tri‐hydrate. High Voltage. https://doi.org/10.1049/hve2.12062

- Kostoglou, N., et al. (2020). Boron nitride nanotubes versus carbon nanotubes: A thermal stability and oxidation behavior study. Nanomaterials. https://doi.org/10.3390/nano10122435

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.