What Equipment is Used in Surface Metrology?

Semiconductor metrology equipment plays a crucial role in the semiconductor manufacturing process. Its primary purpose is to measure and analyze various parameters and characteristics of semiconductor wafers and devices during and after the fabrication process. Such measurements are important for ensuring the functionality and reliability of electronic components. Accurately measuring various properties, such as roughness, layer thickness and topography, also enables manufacturers to optimize production processes, which can significantly improve yields. Surface metrology is likewise critical in non-wafer applications, where it is used to obtain key insights into material properties that influence functionality (i.e. adhesion, fatigue resistance, friction).

Ultimately, accurate surface metrology ensures components meet design specifications and function as intended. This article will explore the various equipment types used in surface metrology.

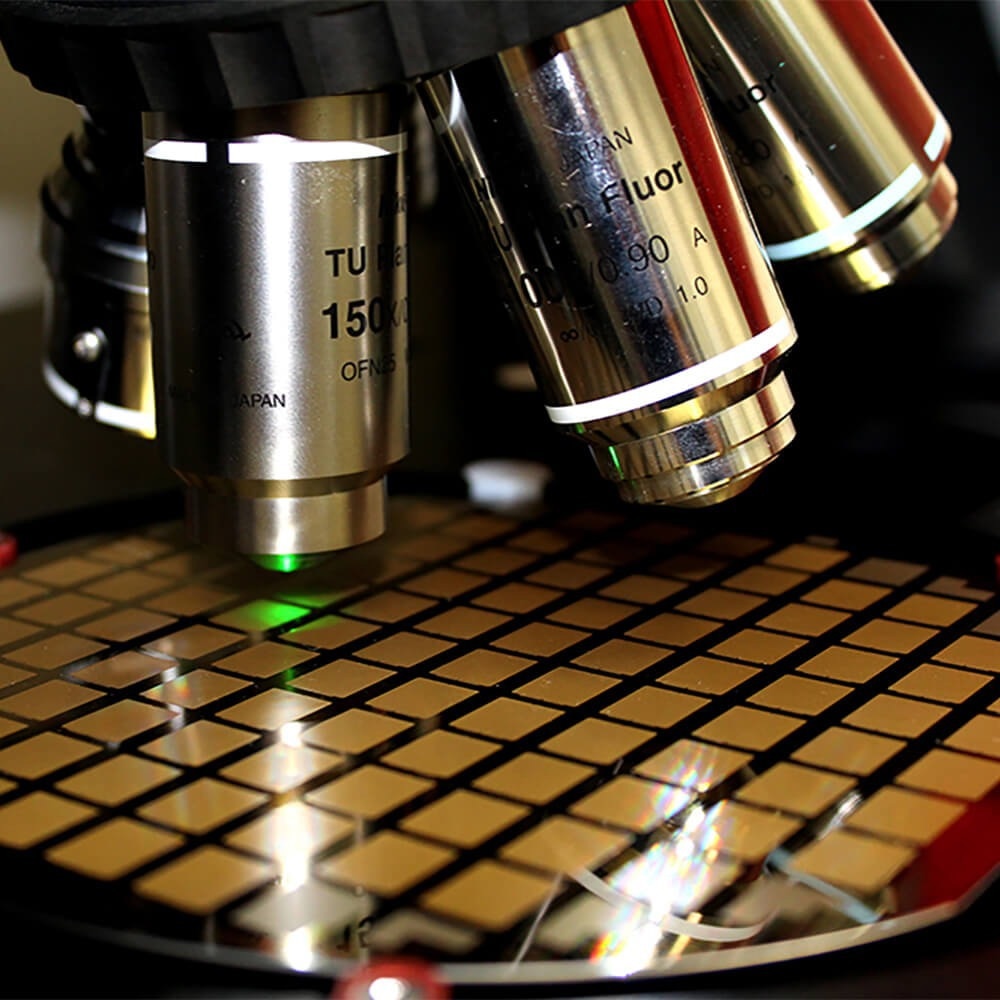

Image Credit: Camtek FRT Metrology

Types of Surface Metrology Equipment

Fully Automated Wafer Metrology

Fully automated wafer metrology tools, such as the MicroProf® FE, merge the functionalities of a 300 mm metrology station with a wafer handling system integrated within an Equipment Front End Module (EFEM). These SEMI-compliant tools are critical in high-volume manufacturing environments, especially within silicon and silicon carbide wafer foundries. They also play a critical role in various 3D packaging process steps.

The MicroProf® FE is a fully automated 2D and 3D wafer metrology tool tailored for front-end applications. Featuring multi-sensor technology, this surface metrology equipment supports hybrid metrology and can handle 300 mm wafers with high throughput. This highly configurable system has additional features, making it suitable for high-volume manufacturing fabs.

Semi-Automated Metrology

Semi-automated metrology tools incorporating a material handling unit (MHU) are tailored for sectors such as MEMS, sapphire, LED, and semiconductor industries. These tools navigate between automation and manual handling, providing a metrology solution that is both efficient and adaptable.

The MicroProf® MHU, equipped with a dual-arm robot for material handling, is well-suited for the semiconductor, MEMS, sapphire and LED industries. This tool combines multi-sensor technology with automated handling, enhancing efficiency and precision in metrology tasks.

Software and Technology for Surface Metrology

Advanced software solutions like Acquire and Mark III evaluation software enhance Camtek's surface metrology tools. These software packages offer user-friendly interfaces and automated measurement capabilities. They also provide comprehensive evaluation and display options in line with industry standards (DIN-EN-ISO and SEMI).

Looking for Surface Metrology Equipment?

We invite you to explore our website to find the full range of details and specifications of our cutting-edge surface metrology solutions. Discover how our fully automated and semi-automated metrology tools can meet your precision measurement needs across various industries. Our inspection and metrology solutions are also available for you to browse. Contact us to learn about FRT metrology and find the right surface metrology solution for your business.

This information has been sourced, reviewed and adapted from materials provided by Camtek FRT Metrology.

For more information on this source, please visit Camtek FRT Metrology.