|

Insaco is a machine shop specializing in ceramic materials. We don’t make these materials but rather process them into something more valuable through our precision machining capabilities. This allows us to be unbiased when it comes to making recommendations as to what material is best suited for a specific application. With over 85,000 square feet dedicated to the diamond grinding of these hard materials, we have become a global leader in this specialized field.

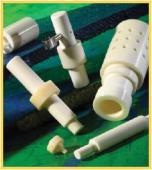

Figure 1. Precision machined ceramic materials

Alternatives to Metals

In numerous applications ferrous materials are the only clear choice, and should be used accordingly. With the advent of exotic hard materials exhibiting superior performance to metallic materials, it’s important to understand that alternatives to metals do exist and should be considered.

Reducing Maintenance Downtime

For example, Insaco recently replaced a ferrous metal roller used in a metal bending application with a ceramic roller. Since these ceramic rollers have yet to be replaced, this has resulted in the elimination of any downtime. Pumping and metering chemically aggressive fluids is another application in which metal parts have been replaced.

Using a high-quality starting material, we are capable of achieving a surface finish of less than 4 micro-inches on an inside diameter of a ceramic tube. This surface finish allows for the plastic plunger to last longer than metal, again reducing downtime and costly field service calls. Insaco have also used various ceramic materials as stops in lapping applications, allowing for precision thickness lapping and extending wear life compared to more conventional metal stops.

Clear Advantages vver Metal

The use of sapphire, ceramics and other hard materials has significant advantages over metal depending on the application. The materials Insaco machine are harder and stronger in compression than most metals. They can be electrically or thermally insulating or conducting, and in the case of sapphire, can be polished optically clear to a surface finish less than 1 microinch.

This allows for selecting material based on the most important material property required and allows for versatility in selecting material which makes the most sense.

Price versus Environment Criteria

In many applications price is the most important determinant. But when a low-cost part must be frequently replaced because of a harsh environment, looking to hard materials may be the key to lowering overall cost. The ability to withstand extreme temperatures, and corrosive environments are just two of a myriad of applications where the replacement of metals with a hard material can mean the difference between success and failure. That’s another area where sapphire excels.

Technical Expertise

Insaco’s technical experts and engineers are well versed on what types of hard materials are best suited for specific applications and can help you in deciding if you should consider replacing your machined metal part with a precision machined hard material.

We Don’t Stop There

Once the selection is made for a material which can withstand the environment, Insaco continue to try and improve the selection process through our extensive knowledge of the properties inherent in ceramics, sapphire etc...

Not Sure About Hard Materials - Give Insaco a Call

The next time you have an application that requires precision machining and you think a metal or plastic material is your only option, think again. Then give Insaco a call and let us help you understand how hard materials just might be a better, more cost efficient, more environmentally sound choice.

|