|

A customer pioneering in the life sciences industry contacted Insaco for a quote on Aluminum Nitride machining for their developmental part requiring excellent hardness and good thermal conductivity. However, they weren’t sure the Aluminum Nitride was the most efficient choice.

Solution

Research by Insaco sales engineers led to a better recommendation to use a CVD graded silicon carbide due to its outstanding thermal conductivity of over 250 W/mK, which is more equivalent to iron or steel, yet offers extreme hardness and wear resistance, even at high temperatures. This material machines well using diamond grinding technology, and there is no real cost penalty. Since Insaco does not produce any materials directly, they can offer unbiased guidance on ceramic material alternatives and their practical limits to size or tolerance.

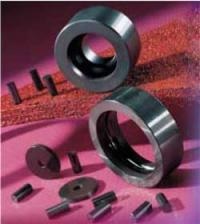

Figure 1. Machined silicon carbide components

Result

The customer was extremely pleased with early prototype results of their part fabricated from the recommended silicon carbide. Production has now launched, and the higher thermal conductivity performance has provided a competitive edge to expand sales.

|

|

|

.jpg)

This information has been sourced, reviewed and adapted from materials provided by INSACO Inc.

For more information on this source, please visit INSACO Inc.