|

Aluminium is becoming increasingly popular for engineering applications. There are many reasons for this that are outlined in the following sections.

Physical/Chemical Advantages of Aluminium

Aluminium is the engineering material of choice for many applications. Properties that make aluminium popular and/or suitable include:

- Light

- Strong

- High strength-to-weight ratio

- Resilient

- Ductile at low temperatures

- Corrosion resistant

- Non-toxic

- Heat conducting

- Reflective

- Electrically conducting

- Non-magnetic

- Non-sparking

- Non-combustible

Product Advantages of Aluminium

Aluminium offers advantages over other engineering materials including:

- Attractive appearance

- Wide range of finishes

- Virtually seamless

- Easy to fabricate

- Joinable by various methods

- Complex, integral shapes

- Easy assembly designs

- Precise, close tolerances

- Uniform quality

- Recyclable

- Cost effective

- Freedom of design

Physical/Chemical Advantages over other Metals and Alloys

Aluminium is approximately 1/3 the weight of iron, steel, copper or brass. This is an advantage in some products and crucial in others.

Reduction in shipping and handling costs.

1 cubic mtr aluminium = 2,700kg

1 cubic mtr steel = 7,800kg

Strength of Aluminium Alloys

By appropriate alloying and treatment, aluminium alloys are available in a variety of strengths.

Some aluminium alloys have strength as high as 300 MPa and are stronger than some steels.

Strength may be selected to match product needs.

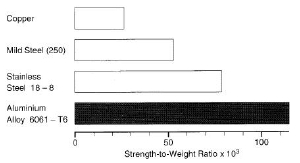

High Strength-To-Weight Ratio of Aluminium Alloys

In terms of strength to weight ratio, aluminium outperforms other materials. Aluminium’s advantage in this respect founded the modern aerospace industry and serves widely in various forms of transportation and other applications.

Resilience under Static and Dynamic Loading

Aluminium products behave elastically under static and dynamic loading conditions, that is, they have the ability to resume both shape and size which is good when flexible strength is required.

Mast and spars of racing yachts are designed to withstand the stress of the wind versus the waves.

Strength at Low Temperatures

Brittle fracture problems do not occur with aluminium. As the temperature is reduced, aluminium alloys increase in strength without loss in quality, making them particularly suitable for low temperature applications.

Used for cryogenics, LNG storage tanks and LNG tankers. An aluminium “moon buggy” was used to negotiate the rough terrain in the deep cold of outer space.

Corrosion Resistance of Aluminium Alloys

When aluminium is exposed to air, a thin oxidised film forms on the surface, protecting the metal from corrosion. When scratched, the layer rapidly reforms retaining the protection. This feature is utilised in construction, buildings and household utensils.

Non Toxic

Aluminium itself is non toxic and odourless. Its surface is smooth, easily washable and hygienic because no germs can grow on it. Thus, it is widely used in beverage cans, food packaging, cooking utensils and in the fishing and dairy industries.

Heat Conducting

Aluminium conducts heat better than any other common metal. It is about three times as thermal conductive as steel. It is important in heat exchange applications - either heating or cooling - and commonly used in the food, chemical, petroleum, aircraft and automotive industries.

Reflective Surface

Aluminium is an excellent reflector of radiant energy. It reflects more than 80% of visible light, radiation (heat) and electric waves. The purer the metal, the more so. This feature is used for reflecting mirrors, reflectors (stoves, infra-red dryers, lighting), and wave guides. It is also used as an insulating material in buildings and as roofing sheet.

Electrically Conductive

Aluminium’s ability to conduct electricity is approximately 62% of that of copper, but it weighs less than 1/3. This means that it conducts about twice as much electricity as copper of the same weight.

Aluminium is a very economical material as an electrical conductor and is used in power transmission cables, bases of electric bulbs and in other electric fields.

Non Magnetic

This property of aluminium makes it particularly useful for a variety of electrical and electronic applications, for high voltage hardware, busbars, magnetic compasses, parabolic antennas, computer disks, etc.

Non Sparking

Aluminium’s non sparking characteristic (against itself and other non ferrous metal) makes it an essential material for products used with highly flammable or explosive substances and atmospheres.

* Petrol pump nozzles are made from non sparking aluminium.

Non Combustible

Aluminium does not burn and so is widely used in buildings, vehicles and in other applications where fire is a potential hazard. Hazardous emissions are not generated when aluminium is exposed to heat.

Product Advantages of Aluminium and Aluminium Alloys

Attractive and Aesthetically Pleasing Finish

The natural metallic surface of aluminium is aesthetically pleasing; the surface supplied is adequate and does not require further finishing. If additional protection is required, the natural oxide film may be thickened by anodising without affecting the metal’s appearance.

Wide Range of Available Finishes

A wide range of finishes may be applied to aluminium to enhance its surface characteristics, or alter its appearance. The metallic surface may be coloured by chemical or anodising processes.

Surface textures may be created, varying from rough to matte to mirror smooth. Coatings such as paint, lacquer, enamel, electroplating or laminate may also be applied.

Virtually Seamless

Aluminium extrusions are seamless one-piece products both visually and functionally. There are no mechanically joined seams to mar appearance or to become loose or leak, even in tubes and other hollow shapes.

Easy to Fabricate

Aluminium can be easily fabricated into various forms such as foil, sheets, shapes, rods, tubes and wires. It also displays excellent machinability and plasticity in bending, cutting and drawing. Aluminium is considered to be the best material for complex extrusion to tight tolerances.

Joinable

Aluminium extrusions can be joined to other aluminium products or to different materials by all major methods, including welding, brazing, soldering, bolting, riveting, clinching, crimping, clipping, adhesive bonding and slide-on, snap together or interlocking joints.

Complex Integral Shapes

Aluminium’s capacity for integral design and production can reduce cost and improve performance and reliability. Extrusion can economically provide product shapes that would be difficult, if not impossible, to produce in any other way.

Aluminium extrusions can be designed for ease of assembly with other parts. The production of large items in the form of dis-assembled kits that require a minimum of manpower and skill to assemble are cost saving.

Aluminium extrusions, of uniform high quality, may be produced in large numbers with minimal rejection rates and little need for corrective fabrication.

Recyclable

The Aluminium industry includes a large “secondary metal” sector which accepts scrapped aluminium products for remelting and recovery of metal. Recycling aluminium requires only 5%of the energy needed to produce new aluminium.

Aluminium extrusions may be recycled and therefore have substantial scrap value.

|