Ceramic tubes are typically used in applications where resistance to corrosion is a requirement. This could be for example, the Chemical & Process industries or the molten metal handling industry. Sialons are alloys of silicon nitride and are characterised by excellent thermal stability and are corrosion resistant to many chemicals and metals, making them ideal for these applications.

Image Credits: International Syalons

Corrosion Resistance of Ceramic Tubes

In the chemical & process industries, the handling and movement of often very corrosive chemicals requires materials with excellent chemical stability. Traditionally, metals such as inconel have been used. However, in many applications inconel has a limited life. International Syalons manufacture Syalon tubes, which in many cases last significantly longer than inconel.

Chemical Resistance of Syalon Tubes

In non-ferrous molten metal handling, the use of Syalon thermocouple protection sheaths and heater and riser tubes demonstrate the material's excellent thermal and chemical behaviour. Syalon 101 and Syalon 050 have outstanding resistance to chemical attack by both acids and alkalis, such as hydrochloric acid, sulphuric acid and sodium hydroxide, gases such as chlorine and molten metals such as aluminium and zinc. They combine this chemical stability with outstanding mechanical and thermal properties, such as high strength and toughness and resistance to thermal shock.

Properties of Syalon Tubes

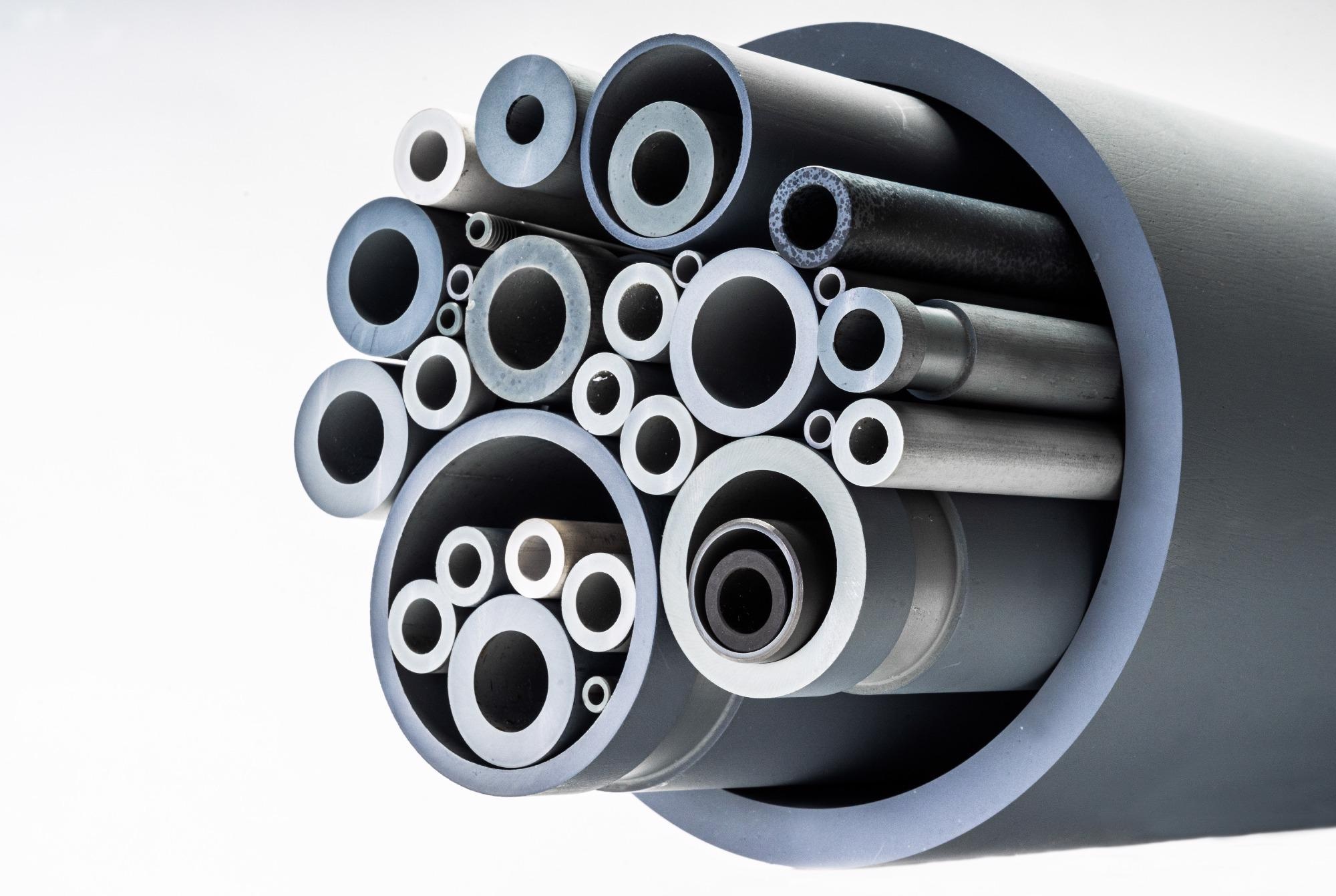

Syalon 101 is most suited to applications below 1200°C, while Syalon 050 performs well up to 1400°C. Sialon tubes are available in a wide range of sizes, as shown in the table below. Many of the sizes are available ex¡Vstock. Other sizes are available upon request.

This information has been sourced, reviewed and adapted from materials provided by Internatrional Syalons.

For more information on this source, please visit International Syalons.