Wax (paraffin) content is an important characteristic affecting the physical properties of petroleum crude oils, in particular their viscosity. Thus, measuring wax content has become a routine analytical requirement for product quality control.

In addition, wax in oils can deposit in downhole pipes, surface equipment and pipelines, and cause blockages, especially at low temperatures. The precise monitoring of the wax content in oils helps to predict and avoid wax blockage so that equipment can be maintained for high quality standards during oil processing.

Determination of Wax in Oils by Conventional Methods

The UOP (Universal Oil Products LLC) solvent extraction method UOP46 is commonly used to determine the wax content of oil by weight. However, this method requires dissolution of the product in acetone, large sample sizes (to guarantee good reproducibility), highly skilled analysts, and long measurement times. Moreover, this technique is unsuitable for the detection of wax components of less than 5% by mass.

Secondary methods for the determination of wax in oil include the pour point method (ASTM D97-66), and the wax appearance method (via polarisation microscopy). Both of these methods are cumbersome, time-consuming and subjective.

In some cases, the wax content can be indirectly calculated using differential scanning calorimetry (DSC) data. However, DSC can be inapplicable for low wax oils; furthermore, sample preparation and DSC measurements usually require a highly skilled operator.

Determination of Wax in Oils by NMR

In contrast to the standard method and the DSC technique, low resolution Nuclear Magnetic Resonance (NMR) provides a fast, direct and user-friendly method for the determination of wax content in oils that can be operated by a non-NMR expert user. This technique is based on measurements of the NMR responses obtained from wax and oil in the product, and quantification of the wax content by calibration.

Advantages of Benchtop NMR

Advantages of Benchtop NMR include:

- NMR is very stable over the long-term, therefore requires little re-calibration

- ‘Setting-up’ samples, with a range of solid contents, are used to check and maintain the original calibration

- The sample measurement time is short (typically 2 seconds)

- The NMR technique is non-destructive, so repeatability measurements can be made conveniently

- Minimal sample preparation is required*

Calibration and Results

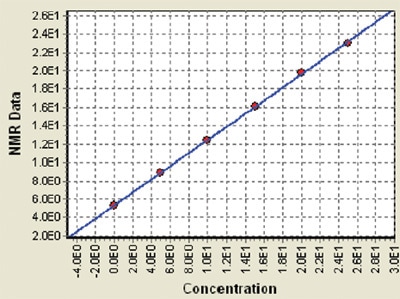

The calibration is generated using at least 6 samples of known wax content spanning the range of concentration of interest. Figure 1 shows a calibration for oils with wax concentrations ranging from 0 to 25 % by mass (weight-%, wt.-%). An excellent linear correlation between the wax NMR response and the wax concentration in the products is obtained.

Figure 1. Calibration obtained for wax content in oils; standard deviation of the linear fitting is 0.13 wt.-%, correlation coefficient R2 = 1.00. Measurements were made using Hitachi High-Tech Analytical Science Benchtop NMR Analyser model MQC-23 equipped with a 10 mm probe. The samples were preconditioned at a temperature of -15°C.

Table 1. Results of instrument repeatability test.

| Given Wax Content wt.% |

Results (wt.%) of

Repeat Measurements |

Mean Wax Content |

Std Dev

wt.% |

| 5 |

5.11 |

4.94 |

4.96 |

5.41 |

5.30 |

5.14 |

0.21 |

The instrument repeatability was tested by measuring one sample five times. After every test measurement, the sample was transferred from the magnet bore back to the conditioning block for 20 min to be conditioned at -15°C and then measured again. Table 1 shows the repeatability test results.

The MQC-23 Benchtop NMR Analyzer

The MQC-23 with 0.55 Tesla magnet (fitted with a 10 or 18 mm diameter probe) is ideal for this application. The ‘Wax in Oil’ package comprises:

- The MQC-23 which can be controlled using its own built-in computer using Microsoft® Windows® or via a stand-alone PC

- Test/tuning sample MultiQuant software including RI Calibration, RI Analysis, and the EasyCal ‘Wax in Oil’ application

- Sample tubes with an outer diameter of 10 or 18 mm (depending on the NMR probe size)

- A set of three Setting-up-Samples for calibration maintenance

- Method Sheet

- Installation Manual

In addition to this package the following equipment is required:

- Refrigerated bath capable of maintaining test samples at -15 or -28°C

- Aluminium block with holes for 10 or 18 mm tubes (depending on the sample tube size)

The instrument offers multiple advantages over other instruments on the market:

- High signal sensitivity

- Small benchtop footprint

- Specific “Wax in Oil” Applications Software

- Low maintenance

- Minimal sample preparation

*Samples require preconditioning at -15 or -28°C for 20 minutes. Depending on the oil composition, the products can be treated in their original state or, in some particular cases, may need additional pre-treatment. To achieve good reproducibility, the method requires 1.5 ml minimum sample volume.

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments Magnetic Resonance.

For more information on this source, please visit Oxford Instruments Magnetic Resonance.