The field of forensic investigation is of increasing importance and thus the role of the Scanning Electron Microscope (SEM) becomes progressively more significant. Due to its ability to examine detail on a wide range of materials in an easily interpreted manner, from high to low magnification with an exceptional depth of focus, the SEM has become an indispensable tool. Together with the ability to analyse the elemental composition of even the smallest features on specimens, it becomes possible to make conclusive identifications of the origin of some materials and thus contribute to the chain of evidence.

Due to its superior performance the SEM is used in an increasing number of various applications and provides valuable results for instance in the following applications:

- Gunshot residue analysis

- Firearms identification (bullet markings comparison)

- Investigation of gemstones and jewellery

- Examination of paint particles and fibres

- Filament bulb investigations at traffic accidents

- Handwriting and print examination / forgery

- Counterfeit bank notes

- Trace comparison

- Examination of non-conducting materials

- High resolution surface imaging

Examples from Case Studies Using Carl Zeiss SEMs

To illustrate some of these world-class capabilities, examples from actual case studies using Carl Zeiss SMT SEMs are described below:

- Gunshot Residue Analysis (GSR)

- Bullet Comparison

- Examination of Non-Conducting Materials

Gunshot Residue Analysis (GSR)

For GSR analysis, specimens are typically collected using double sided tape and transferred to an SEM specimen stub. The system conducts a completely automated search over the stub for particles greater than e.g. 0.5 µm. Particles are automatically detected due to their high contrast with the stub background, using a detector for backscattered electrons. When a particle is detected, the electron beam is returned to the particle for X-ray analysis to check for predetermined elements. If a positive identification is made, the position of each particle is stored for later verification. In general, this automation routine is conducted using an EDS system connected to the SEM. In order for this automation to be successful, the EDS system must be able to remote control the SEM especially the electron beam and stage with long term stability, speed, accuracy and precision, which all of Zeiss SEM series routinely deliver. The new high precision stages have been built to a high level of accuracy. This means that the user can easily return to previously detected particles for further analysis and verification.

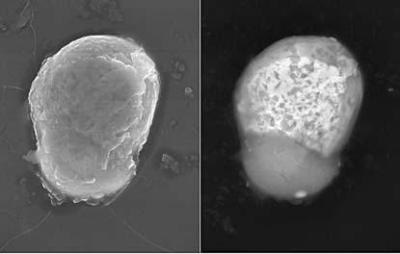

GSR particle in the SUPRATM 55 containing Pb, Ba and Sb. HV mode, 20 kV, 5,000x. Left: SE image. Right : BSE image (4Q-BSD), bright areas are rich Pb-phases and dark areas are rich Ba-phases. Image courtesy of LKA Bayern, Karl Lüftl

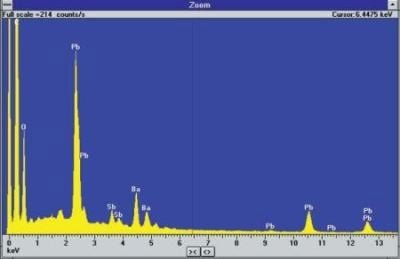

Spectrum from detected particle showing presence of Pb, Ba and Sb

Bullet Comparison

Bullets fired from the same weapon carry distinct markings which are related to the shape of the barrel of the gun. Furthermore it is possible, by matching the characteristic markings on bullets, to conclude whether they were fired by the same gun. Similar markings are made by the firing pin on the cartridge case of the bullets, permitting another method of relating a bullet to a particular gun. Bullets may sometimes be matched using optical techniques. However, optical microscopy lacks the ability to reveal fine detail seen at higher magnifications, and the depth of focus to show it clearly.

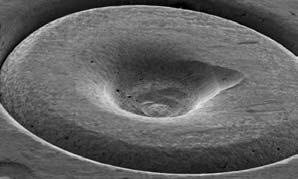

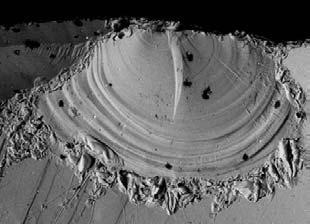

Low magnification, image of a .45 cartridge. Image courtesy of Terry McAdam Washington State Patrol Crime Laboratory Seattle USA

Firing pin impression in centre of a .45 cartridge.

There are three features of our SEM series which deliver real benefits in the comparison of bullet markings:

- Using a backscattered electron detector, the contrast of markings can be enhanced whilst useless information such as dust contamination is suppressed.

- Carl Zeiss SMT offers a purpose designed bullet comparison sub-stage. This sub-stage is capable of holding either bullets or cartridge cases. Each bullet may be rotated independently of the other so that an exact match can be made.

- Images, and even parts of images, can be cut and pasted onto each other and aligned so as to aid the matching process.

Examination of Non-Conducting Materials

One of the traditional drawbacks of conventional scanning electron microscopy is that specimens must be conductive. Non-conducting materials need to be coated with a conducting material, such as gold or carbon. Coating is especially undesirable in forensic examination, as it is important for evidence to remain unaltered. This is no longer the case using our SEMs with VP or EP mode. These features allow the user to adjust the chamber pressure to a level which prevents the specimen from charging since the chamber atmosphere itself dissipates the charge. Even completely non-conducting specimens such as paper, paint, textile tissue, hair or plants can be examined at low kV and analysed using EDS without the need for specimen preparation thus preserving the sample in its natural state. The same is also true for moist or even porous specimens such as concrete or bone. SE-imaging and EDS-analysis clearly shows the difference between diamond, an insulator, and its synthetic substitute moissanite being a semiconductor.

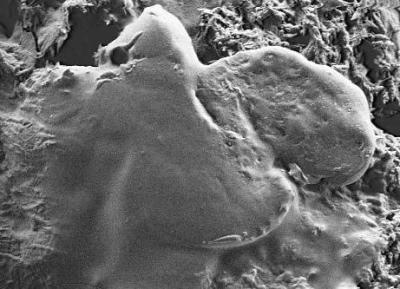

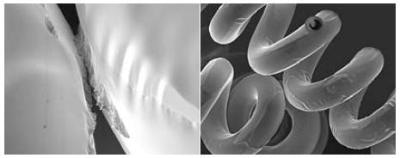

Ball-pen paste on laser printed document in the SUPRATM 55. HV mode, 1 kV. No toner particle visible on the ball-pen paste is the proof of no falsification.

Variable Pressure image: Glass (uncoated).

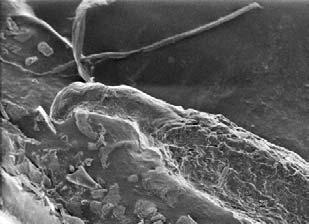

Hair root showing the follicular tag piece of skin used to show whether hair was forcibly removed from the scalp follicle (uncoated).

One side of marijuana leaf (the bear-claw shaped trichomes aid in identification).

General Requirements for Scanning Electron Microscopes in Forensic Investigations

By the very nature of the wide variety of crimes under investigation and the subsequent evidence requiring examination, the ideal forensic SEM needs to be as versatile as possible. The SEMs from Carl Zeiss SMT are designed to provide the ultimate in versatility and performance:

- Tungsten, LaB6 or field emitter emission system.

- Large specimen chambers and various stages to accommodate diverse specimen types.

- Accelerating voltage adjustable in 10 V steps from 0.1 to 30 kV so that the exact voltage can be chosen to match the type of work being carried out.

- Various additional ports are provided as standard so that the instrument’s capabilities can be expanded.

- Ultra high resolution image processor, ensuring that the first image detail is captured and can be further analysed at a later date.

- Turbomolecular pumping giving a fast throughput of specimens and a high degree of vacuum cleanliness.

- The geometry of the various chambers and stages has been optimised for multi-detector operation.

- Various display modes e.g. Split Screen allow direct comparison of different evidences such as rifling impressions, marks and other traces, even with different detectors.

- Enhanced VPSE detector to enable critical imaging of currency and documents in VP mode.

- Open software structure enabling the implementation of third party software e.g. for 3D-reconstruction.

Vehicle lamp filament from an accident imaged with the SUPRATM 55. Left: Overview at 189 x, 5 kV, showing depth of focus. Right: High resolution image at 2,100x, 5 kV, showing melting contacts coused during the accident. Image courtesy of LKA Bayern, Karl Lüftl

EVO® MA 15

Scanning Electron Microscopes for Forensic Applications

Scanning electron microscopes available for forensic applications by Carl Zeiss include:

Multi purpose SEMs

- EVO® MA 10 and EVO® LS 10

- EVO® MA 15 and EVO® LS 15

- EVO® MA 25 and EVO® LS 25

Field emission SEMs

- SUPRA™ 25

- SUPRA™ 40 / 40VP

- SUPRA™ 50 / 50 VP

- SUPRA™ 55 / 55 VP

- ULTRA 55

Accessories for Scanning Electron Microscopes

Accessories available for SEMs by Carl Zeiss include:

- Bullet comparison stage

- Peltier cooling sub-stage

- Microanalysis module

- Large specimen holders

- Combined hot/cold stage

- Airlock

- Electrical feedthrough

- Multiple sample holder

- Cryo preparation stage

- Tensile stage

Additional Detectors for Scanning Electron Microscopes

Additional detectors available for SEMs by Carl Zeiss include:

- Variable Pressure SE detector

- Extended Pressure SE detector

- Backscattered electron detectors

- Multi-mode STEM detector

- Specimen current detector

- Cathodoluminescence detector

- Faraday cup

- EDS & WDS

Software for Scanning Electron Microscopes

Softwares available for SEMs by Carl Zeiss include:

- GSR packages from various EDS suppliers

- Image analysis for general applications

- 3D-reconstruction for measuring of depth and shape

This information has been sourced, reviewed and adapted from materials provided by Carl Zeiss Microscopy GmbH.

For more information on this source, please visit Carl Zeiss Microscopy GmbH.