The presence of water in oil in different forms, from free water to emulsified to dissolved, can be monitored using the FluidScan mid-infrared spectrometer from Spectro Scientific. Using the fundamental chemistry describing the existence of water in oil, FluidScan accurately measures dissolved water in oil.

With FluidScan, users can be alert when these conditions exist at critical levels. It is necessary to ensure that the water status is homogenous while comparing results between FluidScan and Karl Fischer laboratory titration techniques. It is possible to perform quantitative comparisons when the water is largely dissolved in the oil. This article discusses the application of FluidScan to measure the dissolved water in oil.

FluidScan Mid-Infrared Spectrometer

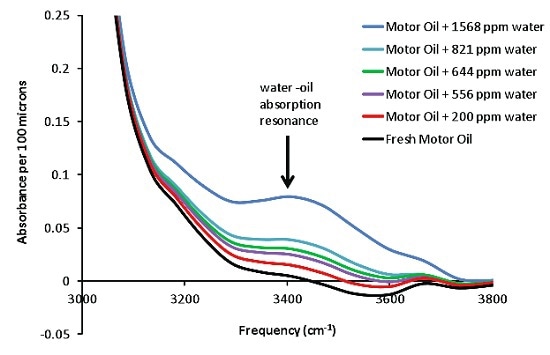

During the interaction of water and oil, signature chemical bonds are formed between their molecules. Since the bonded water-oil molecules demonstrate strong mid-infrared resonances, they likely absorb mid-infrared energy at particular vibrational frequencies. FluidScan mainly focuses on sensitive oxygen- hydrogen bond resonance (O-H stretch), which takes place between the ‘dissolved’ water and oil. The presence of more dissolved water in the oil continuously increases the absorption resonance as shown in Figure 1.

Figure 1. An example of dissolved water absorption in motor oil: FluidScan spectra depicting a series of motor oil samples with increasing amounts of water. The main absorption resonance is centered at 3400 cm-1.

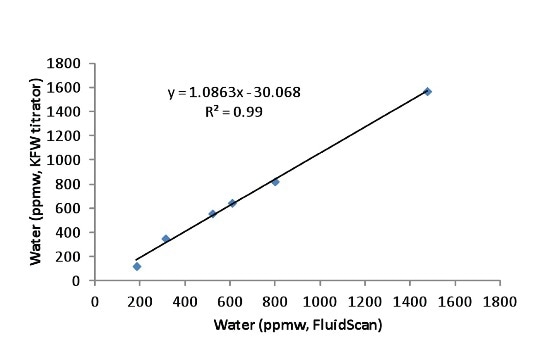

The comparison of FluidScan results for the dissolved water in oil and Karl Fischer standard laboratory titration results is shown in Figure 2. There is an excellent correlation between these two results.

Figure 2. Comparison of FluidScan water readings from the analysis of the spectra in Figure 1 to ASTM D6304 Karl Fischer water titration.

Sample Analysis with FluidScan Mid-Infrared Spectrometer

The sample analysis and corresponding ppm reading by FluidScan involve the following steps:

- The spectrum of the oil is measured by FluidScan and that spectrum is the basis of the height of the water peak as quantified by embedded analysis algorithms

- That height is then converted into a ppm utilizing an algorithm stored within the device. Irrespective of the type of oil, this signature peak exists during the formation of bonds between water and oil. This provides a direct and reliable approach for FluidScan to analyze water content in oil.

- The application of an algorithm in determining this peak’s true height eliminates other scenarios in oil from the true water determination with activity in the mid-infrared region.

- In cases where infrared peaks take place in the same mid-infrared region, for instance the presence of sizeable amount of antifreeze contamination in the oil, FluidScan can detect and flag other peaks related to those chemical contaminants other than the water contamination.

Applications of FluidScan Mid-Infrared Spectrometer

FluidScan mid-infrared spectrometer is an ideal device capable of detecting different forms of water contamination in oil. The presence of water in oil results in an unambiguous, repeatable and large absorption resonance. FluidScan is capable of readily quantifying and tracking for almost all types of oil, including biodiesel.

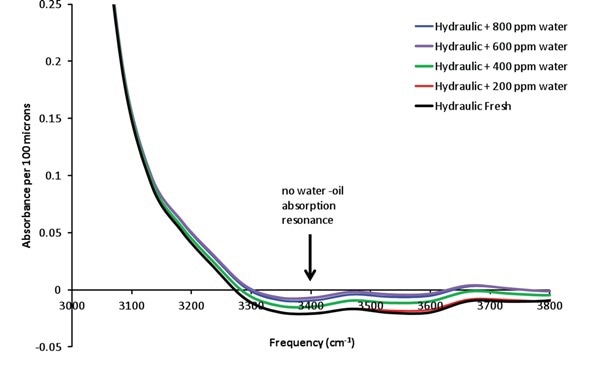

Through its characteristic infrared scattering, FluidScan identifies the presence of emulsified and free water and alerts the operator when they go beyond pre-defined threshold values by sensing the increase in the absorbance spectrum using embedded algorithms. This case is illustrated in Figure 3. In these cases, FluidScan will deliver an indication instead of a quantitative value of the total amount of water present in the oil.

The characteristics of the oil formulation as well as sample preparation conditions decide the forms of water present in the oil.

Figure 3. Infrared signature of emulsified and free water in oil: The presence of such contaminants is marked by elevated absorption across the infrared with no peak, a signature of the scattering of the infrared light by the water.

Many oils are engineered to dissolve as much water as possible to facilitate the removal of water from the machinery. In these situations, FluidScan can readily observe and accurately quantify dissolved water peaks, up to the saturation point.

Other oils, including hydraulics that are suitable to handle sizeable amount of water well above the saturation limit of any type of oil, are engineered for their demulsibility characteristics (i.e., their capability to prevent bonding with water). Hence, water removal from the system is done by other methods. In such situations, FluidScan informs the operator to extreme contamination conditions.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.