Springs have become a fact of life since the industrial revolution, and compression/tension springs are the first that come to people’s mind when they try to image a spring. They are utilized in a myriad of applications, including automotive engine, large stamping presses, vehicle suspensions, lawn mower, major appliances, pens, cell phones, medical devices, electronics and sensitive instrumentation devices, to name a few.

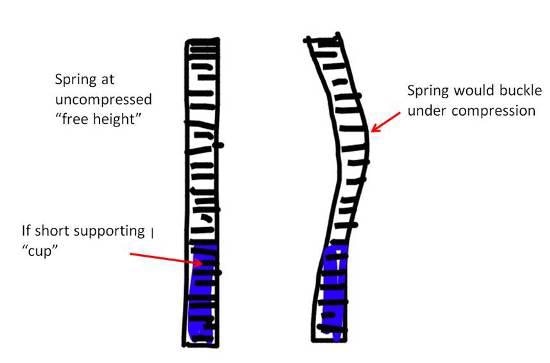

Spring manufacturers have given attention to ensure the quality of springs by testing them under different ranges of compression and tension forces. These tests help a manufacturer to determine the performance of its springs in a specific job for which they have been made for. However, these tests face a common problem in the form of buckling of the spring under compression forces.

Tinius Olsen’s Solution

For the aforementioned problem, Tinius Olsen engineers found a solution that utilizes a supporting post attached to the lower compression platens to center the spring in order to adequately support the test piece when the compression load is applied. It is simple to apply this configuration to a standard S or T series testing machine from Tinius Olsen. This configuration delivers excellent results for stiff, short or wide springs.

On the other hand, if the spring to be tested is especially long, then a support post that goes the entire length of the spring is needed. In this case, the support post has to go through the cross head. The suitable solution is a machine configuration that has the load cell on the machine base and allows the support post to pass through the crosshead when it compresses the spring. This setup avoids spring buckling and provides highly accurate test reports. It works well with a standard U-series testing machine from Tinius Olsen.

This information has been sourced, reviewed and adapted from materials provided by Tinius Olsen.

For more information on this source, please visit Tinius Olsen.