Seat belts are considered as one of the key technologies available in any car. Every new car features seat belt fabrics of about 14 m long and weight of approximately 0.8 Kg. People may wonder how a piece of cloth can play a key role in the safety of passengers. However, seat belts save the life of roughly 13,000 people in the US every year, according to a report from the National Highway Traffic and Safety Administration.

Testing Strength and Performance of Seat Belts

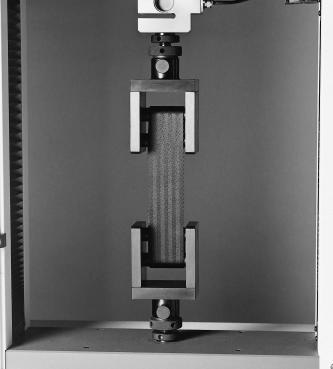

Tinius Olsen tensile testing machines are being used by several key seat belt manufacturers all across the world in order to assess the strength and performance of seat belts and related components. The combination of the H100K-U tensile testing machine from Tinius Olsen and test specific grips HT43 proves to be the ideal solution to test seat belts according to the specifications outlined in the international standards, including BS 3254 and ASTM D6775.

Since a high level of energy is stored in seat belts before breaking, the occurrence of rupture is aggressive. Hence, in order to give protection to users and collect component fragments, Tinius Olsen provides a wide choice of safety screens that are compatible with its U series tensile machines. Moreover, the Tinius Olsen Horizon software provides an output graph that plots force against displacement as a graphical representation of the performance of seat belts during tests.

This information has been sourced, reviewed and adapted from materials provided by Tinius Olsen.

For more information on this source, please visit Tinius Olsen.