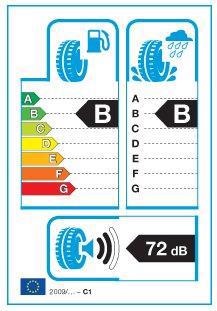

Tire manufacturers need to be vigilant and well positioned for every quality test as they need to ensure quality in order to fulfill the specifications of new and evolving global quality standards. The European Union has recently released marking standards for international tire manufacturers who supply products to the European market.

Figure 1. EU Tire Specifications

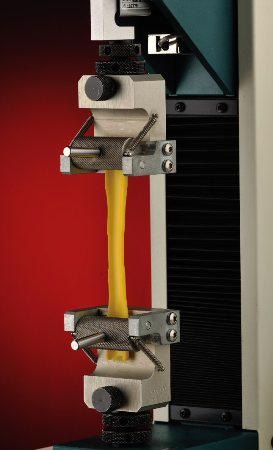

Tinius Olsen’s Solutions for Testing Tire Quality

Tinius Olsen offers a variety of products to help global tire manufacturers to maintain and ensure the quality of their products with regards to the specifications outlined in the stringent marking standards. The company follows different international standards.

Figure 2. Mechanical testing machines from Tinius Olsen

The following are the products offered by Tinius Olsen for global tire manufacturers:

- Extensometers - To take precise measurement of strain

- 100R – Contact type model 100R with 10 µm resolution, up to 1000 mm travel, and multiple gauge length capability of 10-100 mm

- 500L – Non contacting type model 500L with 12 µm resolution, scan speed of 320 times per second, and multiple gauge length of 10 mm to as high as 500mm

- Video Extensometers – Non-contacting type instrument designed for users who demand a video capture for post-test analysis in addition to strain data and results

- Machine – H5K and H10K tension/compression machine

- Environmental Chambers – Optional temperature chambers to support rubber testing at elevated and cold temperatures

- Grips – 137-004, 187-005, 187-006 roller grips for holding the specimen during testing

- Horizon Software – Facilitates a wide variety of tests for the quantification of the performance of rubber in compression, puncture, tear and tension modes

This information has been sourced, reviewed and adapted from materials provided by Tinius Olsen.

For more information on this source, please visit Tinius Olsen.