Mid-Infrared (Mid-IR) spectroscopy is a technique which is often employed for lubricant formulation and evaluation as it provides comprehensive data on chemical composition. This technique is now being used as a condition monitoring tool in laboratories across the globe, offering degradation data of in-service lubricants by quantifying Nitration, Sulfation, Oxidation, Soot and Antiwear Additive depletion.

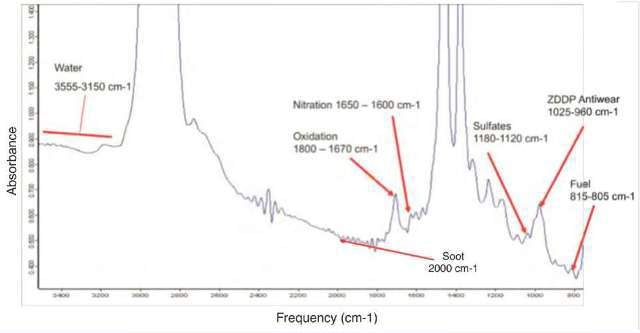

A standard infrared spectrum of an oil sample is illustrated in figure 1. The spectrum’s regions used to measure usual oil condition parameters are highlighted to demonstrate how the IR spectrums are used for this purpose.

Figure 1. A typical infrared spectrum of in-service oil and parameters extracted from the spectrum. A laboratory FTIR spectrometer is a common tool to provide such information. A lab technician or data analyst then interprets the spectrum and provides quantitative information about the oil condition.

Generally, such spectrums are acquired in laboratories using a Fourier Transform Infrared Spectrometer (FTIR), and the study is carried out by a trained lab technician. However, FTIR spectrometers are not used owing to the problems of sample introduction, miniaturization and the need for direct and high-quality data sans a trained oil analyst.

FluidScan: A Revolutionary Device

The United States Department of Defense required a rugged oil condition monitoring tool for field applications. In response to this need, Spectro developed a portable, infrared oil analyzer called FluidScan. This tool measures the degradation and contamination of the oil chemistry, and helps verify whether a new oil is of the proper type and free of impurities. The tool is suitable for condition monitoring of in-service machinery oil in compressors, turbines and gearboxes.

FluidScan is an ideal oil condition monitoring tool and combines the power of a FTIR spectrometer, a TAN/TBN Titrator and a Karl Fischer Titrator into a single field-based, portable device, without compromising core analyses. At present, FluidScan is widely utilized to maintain critical assets across the globe, including power generation equipment, mining fleets and marine vessels. Some of the original design considerations and how innovative technologies are employed in FluidScan to satisfy the design criteria are described in the flowing paragraphs.

Design Criteria

Prior to designing a hand-held infrared oil analyzer, a list of design criteria was set to ensure that the final device have the required characteristics, such as durability, size and weight, parameter sensitivity, and battery run time. Other criteria specified that solvent should not be used in between tests to simplify operation in the field. However, there were certain difficulties in meeting all the design criteria but this was overcome with innovative solutions. For instance, a new sample introduction method was devised to eliminate the use of solvent in the field; considerable effort was also put into balancing the requirement of size, weight and battery running time and simultaneously ensuring the equivalency of the device’s analytical capability to FTIR spectrometers for in-service oil analysis.

The Final Design of FluidScan

Figure 2 shows the final design of the FluidScan. A grating dispersive optical system with a solid state wave guide is the heart of the device that reduces light leakage and enhances signal-to-noise ratio. The device has two IR lamps, one with a shortpass wavelength filter joined together with a beamsplitter and one with a longpass wavelength filter. This design approach removes moving parts from the system and also does away with frequent recalibration needs for field use.

Figure 2. Schematic of FluidScan hardware, including IR source, fliptop cell, and grating optics. There are no moving parts in this design.

Solvent-free Sample Introduction

For field-based oil analysis, easy and repeatable sample introduction is important. A transmission cell is typically utilized and the amount of light absorbed against frequency passing via 100 µm of an oil sample is recorded. However, transmission cells are not suited for field use since solvent is required for cleaning after the sample has been tested. To deal with this issue, a new sample introduction method called flip-top cell was developed.

Figure 3. Fliptop cell (RHS) and schematic wedged window design (LHS).

The flip-top cell removes the need for solvents for cleaning and maintains the same quality of a transmission cell utilized in lab environments. Moreover, in order to attain equivalency to FTIR for in- service oil analysis, significant effort was made to improve the signal-to-noise ratio (SNR) of the handheld device.

Conclusion

FluidScan is an ideal oil condition monitoring tool that provides laboratory quality measurement to on-site oil analysis instruments. FluidScan combines the power of a FTIR, Karl Fischer water titrator and aTAN/TBN titrator to monitor the oil condition anywhere and anytime.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.