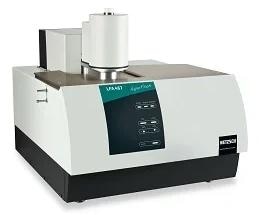

The LFA 467 HyperFlash® from NETZSCH is a light flash apparatus with unique proportions for measuring thermal diffusivity and conductivity. It is compatible with a wide range of commercially available attachments, allowing the instrument to handle entirely new dimensions in thermophysical property measurement.

Image Credit: NETZSCH-Gerätebau GmbH

The sample holder is intended to hold 16 samples, allowing up to four times the sample throughput with minimal operating time and effort.

Refill mechanisms are supplied for automated refilling of the Dewar on both the furnace and the detector, allowing the LFA system to operate continuously and without interruption.

Key Features

The LFA 467 HyperFlash® provides the following features:

- Simultaneous measurement of up to 16 samples over the whole temperature range

- Fast and simple

- Single instrument setup

- Economical

- Widest temperature range from -100 °C to 500 °C

- No need to replace the detector or the furnace.

Netzsch LFA467 EN

Video Credit: NETZSCH-Gerätebau GmbH

LFA 467 HT HyperFlash® – Thermal Diffusivity and Conductivity

The LFA 467 HT HyperFlash® is based on the well-established LFA 467 HyperFlash® technology and does not require a laser class owing to its revolutionary light source mechanism. The xenon lamp’s extended lifespan allows cost-effective examinations over 1250 °C without expensive consumables.

Image Credit: NETZSCH-Gerätebau GmbH

ZoomOptics – For Precise Measurement Results by an Optimized Field of View

The unique ZoomOptics technology (patent no.: DE 10 2012 106 955 B4 2014.04.03) improves the detector's field of vision, reducing the effects of aperture stops. As a result, measurement precision improves significantly.

Ultra-Fast Sampling Rate (up to 2 MHz) and Extremely Short Pulse Widths (up to 20 µs) Enabling Measurement of Thin and Highly Conducting Materials

The LFA 467 HyperFlash® series now has a 2 MHz data acquisition rate. The pulse mapping channels and the IR detector are subject to this acquisition rate. This makes it possible to test thin and highly conductive materials with outstanding dependability in short test durations.

An ideal sample rate and pulse width can be chosen for evaluating metal (0.3 mm) and polymer foils (30 µm). The patented pulse mapping system considers the finite pulse width effect and heat losses (patent no.: US7038209 B2; US20040079886; DE1024241).