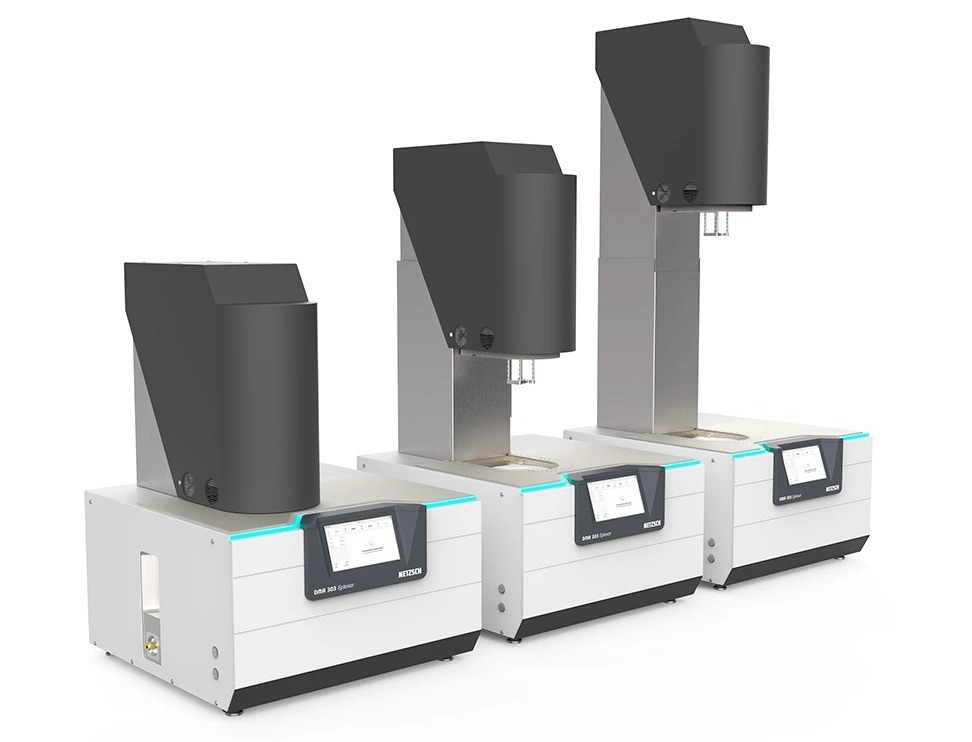

The DMA 303 Eplexor is a highly accurate and dependable analysis instrument that is capable of handling a wide range of samples and applications. Thanks to its user-friendly software and improved ergonomics, it is the ideal instrument for use in quality control and research laboratories.

The DMA 303 Eplexor is incredibly adaptable and can handle a wide range of samples and applications. Thanks to its many accessories, like sample holders and cooling systems, it can support a wide range of testing requirements.

As well as its user-friendly software, the DMA 303 Eplexor offers significantly enhanced ergonomics, meaning that daily operation is relatively easy. Moreover, its various add-on options make it an ideal device and a safe long-term investment.

DMA 303 Eplexor

DMA 303 Eplexor in summary. Video Credit: NETZSCH-Gerätebau GmbH

Broad Temperature and Force Range

800 °C

Temperature range: –170 °C to 800 °C

50 N

Force range: 1 mN to 50 N

30 mm

Static deformation: up to 30 mm

Improving the Products Requires Expert Technical Knowledge Along With Material Analysis — Netzesch Offers Both

Controlled Force Range up to 50 N (Static and Dynamic)

The material testing system is intended for precise measurements on very stiff samples with a static and dynamic force range of up to 50 N. The full resolution is available throughout the entire force range, resulting in precise and reliable data.

Temperatures of up to 800 °C on the Sample

Features the widest temperature range, from –170 °C to 800 °C, as well as homogeneous temperature distribution.

Time Saving — Fast Heating and Cooling

As a result of its thin-walled 3D-printed silicon carbide furnace lining, the system minimizes waiting times with fast heating and cooling and facilitates homogeneous temperature distribution thanks to two independent temperature control loops.

Perfect for the Execution of Creep and Relaxation Experiments

With a range of up to 30 mm, the independent stepper motor drive is ideal for non-oscillatory investigations such as tensile or compression tests, creep and relaxation.

Suspended Sample Holder Design

The suspended sample holder system, together with the option to modify the instrument’s height, promotes the best possible workplace ergonomics. In addition, this setup safeguards the sensitive measuring system from the interference of falling sample fragments.

Various Cooling Options to Suit the Requirements

i.e., liquid nitrogen-controlled cooling down to -170°C, or AIC 80 intracooler for measurements below room temperature, down to -70°C.

Technical Data

Frequency Range

Position Resolution

Maximum Controlled Amplitude

Get the Job Done More Easily

Image Credit: NETZSCH-Gerätebau GmbH

The Most User-Friendly DMA Users Have Ever Experienced

Back-Friendly: Highly Ergonomic Design

The sample holder area’s height can be modified to enable ergonomic work regardless of the user’s height or choice of standing or sitting.

Easy On the Eyes: Illuminated Sample Holder Area

The integrated light source provides additional illumination and makes specimen and sample holder exchange even more comfortable.

Instant Access to Important Information: Color Info Display and LED Status Bar

The embedded LED status bar informs users of the measurement’s progress as well as the force, frequency, and temperature employed.

Intuitive and Tool-Less. No More Cumbersome Exchanging of Sample Holders and Specimens

The instrument allows for convenient switching between a variety of sample holders. It auto-detects sample holders and selects the correct calibration. The exchange is tool-free and, due to fixed guides, sample holders are easy to install.

Research Without Limits: Over 20 Different Sample Holders From Which to Choose

The most recent sample holders have been built for maximum adaptability to measurement conditions and material attributes to serve a wide range of applications. For optimal performance, additional design adjustments give excellent frame rigidity with very low Thermal Conductivity.

The NETZSCH Dynamic-Mechanical Analyzer DMA 303 Eplexor presented by Dr. Jürgen Blumm

Video Credit: NETZSCH-Gerätebau GmbH

A Single DMA that Meets All Users Needs

Flexibility and Convenience: Even When It Comes to Software and Accessories

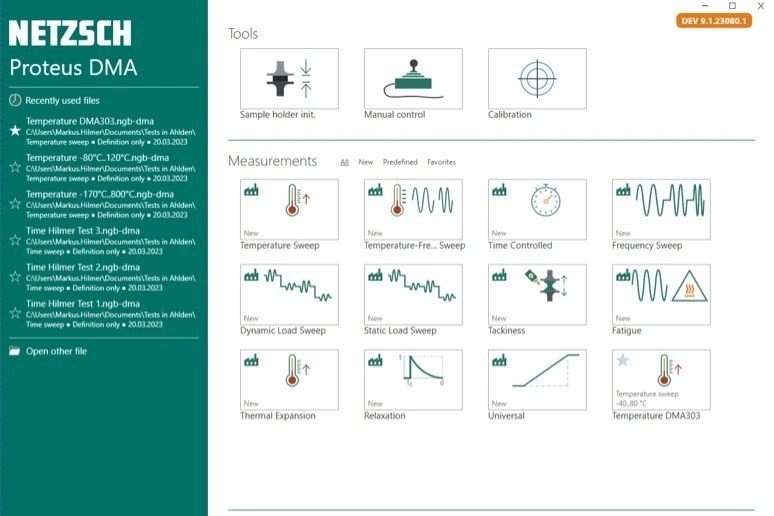

PROTEUS® Software

The most recent Proteus® dynamic mechanical analysis program has a clean and simple graphic user interface that makes it easy to explore and use the product to its maximum capacity.

It saves time by allowing recent measurements to be easily opened or rerun. It also provides predefined templates to help users quickly and efficiently start new measurements.

Templates are available to satisfy a variety of testing purposes and can be changed to match individual needs.

Manual control provides direct access to static and dynamic load, temperature, and gases. Calibration methods, which may be performed by an operator without the need for any external service, produce accurate and dependable results.

During an ongoing measurement, data is shown as an on-screen graph with a freely configurable axis or as a list of signals. After the experiment is finished, the data is imported into the Proteus® analysis software, which includes extensive evaluation capabilities.

Image Credit: NETZSCH-Gerätebau GmbH

AUTOEVALUATION and Identify

AutoEvaluation, a self-acting evaluation routine for DSC/DMA curves, was designed to evaluate onset temperatures in E‘, peak temperatures in E‘‘, and tan δ for glass transitions fully autonomously and without user intervention.

In addition to its autonomous functionality, the evaluation results that it produces can be taken by experienced users as a second opinion. With AutoEvaluation, users can modify or add calculations of values for the most precise results possible.

Identify enables measurement identification and classification via database comparison. In addition to one-on-one comparisons, Identify allows users to determine whether a specific curve belongs to a specific class.

These classes can be made up of curves of the same material type (material identification) or of pass/fail reference curves (quality control). This feature facilitates the identification of materials and allows users to meet quality control norms.

Accessories

NETZSCH introduces the next generation of DMA sample holders in conjunction with the DMA 303 Eplexor. They have a one-of-a-kind low-mass design that allows for precise and accurate measurements.

There are heat-resistant steel sample carriers available for great stiffness, even at high temperatures. Alternatively, a unique titanium alloy sample holder with minimal inertia and very low Thermal Conductivity yields ideal results.

Integrated guides on the sample frame help with correct insertion, and the design enables time-saving, toolless installation.

RFID technology automatically recognizes the frame and probe used and picks the appropriate calibration in the software. This feature saves users time while also ensuring accurate and dependable results.

Image Credit: NETZSCH-Gerätebau GmbH