The Cryogenic Silicon Analysis System (CryoSAS) from Bruker is a dedicated all-in-one system designed for the low-temperature (<15K) impurity analysis of Silicon. This system is optimized for use in the industrial environment.

CryoSAS combines the high performance FTIR spectrometers from Bruker with an integrated, closed-cycle cryo-cooling technique that does not liquid Helium. All of the components of CryoSAS are state-of-the-art, but they still utilize proven technologies to achieve a complex analysis in the demanding silicon production environment. CryoSAS can be operated at a high automation level including accurate reporting of the test results.

Features include

High sensitivity

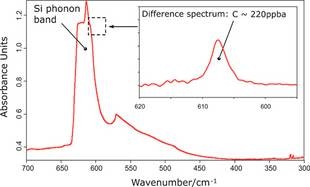

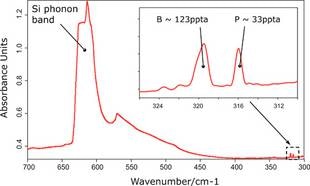

CryoSAS analyzes shallow impurities (for example Phosphorous, Boron, etc.) down to the low ppta level in accordance with the ASTM/SEMI MF1630 standard. Additionally, it simultaneously analyzes Oxygen and Carbon down to the low ppba level in accordance with the ASTM/SEMI MF1391 standard.

CryoSAS measurement results for carbon (see above) as well as for Boron and Phosphorus (see below) at low temperatures (~12 K).

Closed-cycle cryogenic refrigeration system: no expensive liquid cryogens needed

CryoSAS includes a highly reliable closed cycle cryo-cooling technique for detector and sample chamber cooling. This closed cycle system can save € 50,000 in operation costs per year and even more.

CryoSAS low temperature sample compartment with automated 9 position sample holder.

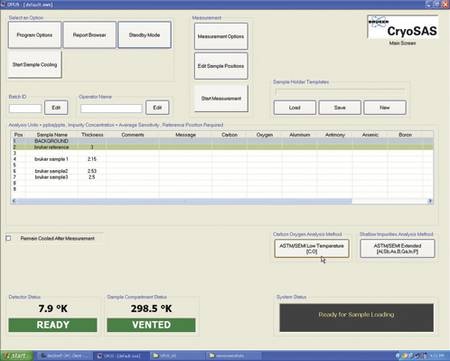

CryoSAS main software screen displaying the currently loaded samples and the chosen analysis methods.

Stainless steel sample chamber design: easy sample access

CryoSAS comes with a proven sample chamber design and automatic sample head and stationary optics. The large inner diameter of the sample chamber allows easy access to the sample holder.

Dry fore pump and turbo pump: simple and clean vacuum system operation

CryoSAS provides reliable and fast evacuation through dry fore pump and turbodrag pump.

Robust, precision stepper motor stage with nine position sample holder:

The rugged translation stage connected to the sample holder allows multiple sample analysis. The solid translation mechanism and high torque motor provide precise sample indexing and many years of reliable functionality. Samples can be easily installed and removed, and the sample holder can be easily attached in the sample chamber. The sample holder’s gold-coated OFHC copper design ensures uniform temperatures.

Ease of use

CryoSAS is optimized for use in the industrial environment. A PLC controls all vacuum and refrigeration devices. Starting the measurement and cooling down are performed with a simple push button operation. The user does not have to be a vacuum expert or a spectroscopy expert to perform the operation.

CryoSAS’ dedicated software is designed to meet the requirements of industrial quality control. It can be easily used and operated via touch screen. The user can simply select the preferred analysis method, input the sample information and press the start button. Then, the CryoSAS will automatically cool down the samples, begin the infrared measurement, assess the results and create an analysis report.

Specifications

Spectral range: 1500 – 280 cm-1 improved for the detection of

- Group III and V shallow impurities in single crystal Si in accordance with ASTM/SEMI MF1630 standard. For wedged samples with a thickness of approximately 3 mm, the following detection limits can be reached:

- 10 ppta Phosphorus

- 30 ppta Boron

- Substitutional Carbon in accordance with the ASTM/SEMI MF1391 standard. This method needs a Carbon free FZ reference sample with thickness and surface properties compared to the sample specimen. For a wedged sample with a thickness of about 3 mm, Carbon concentrations down to 20 ppba can be detected.

Technologies used in CryoSAS are protected by one or more of the following patents: US 5309217; DE 4212143; US 7034944; US 5923422; DE 19704598

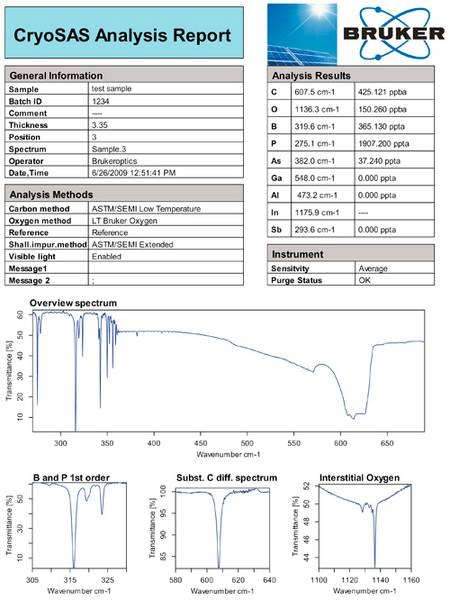

Typical CryoSAS analysis report including all relevant informations and results.