PEEK is a high-performance material with one of the highest strength-to-weight ratios of all engineered polymer. The material is a highly rigid plastic with exceptional lubricity and offers a non-stop working temperature of 500 °F (260 °C). PEEK can be used as an alternative to other materials including steel, aluminum, and glass when it is extruded.

PEEK is used in numerous industries such as High Performance Liquid Chromatography (HPLC) due to its strength. In these analytical applications, the enhanced tensile strength provides improved burst pressure when extruded in tubing form.

Medical applications are increasingly using more PEEK when more pushabilty and torque are required for advanced catheter componentry. In tough applications such as oil and gas, PEEK is commonly extruded as a coating over fiber optics and also extruded over magnet and lead wires for motors that need advanced insulation that is chemical and abrasion resistant.

The aerospace sector utilizes PEEK due to its strength and resistance to abrasion and flame-protecting cable, wire, and fiber optics.

Fillers are provided with PTFE extrusions:

- Carbon

- Boron Nitride

- Barium Sulfate

Applications

The main applications of the PEEK material are as follows:

- HPLC/analytical tubing

- Catheter componentry

- Thermally stable fiber optic coatings

- Wire and cable insulation

Products

PEEK material is used in:

- Tight tolerance custom extrusions

- PEEKshrink® (PEEK heat shrink)

- Drawn fiber

- Lay-Flat® tubing

- Insulated Wire

- Convoluted tubing

- Monofilament

- Special profiles

- Coated optical fiber v

- Multi-Lumen

Key Properties

The key properties of the PEEK material are as follows:

- Lubricious

- Lightweight

- Biocompatible

- High temperature resistance

- Ideal stainless steel replacement

- Exceptional purity

- High burst pressure

- Limiting oxygen index 35% at 3.2 mm

- Thermoformable

- Outstanding torsional stability

- Resistant to gamma radiation

- Superior wear and impact resistance

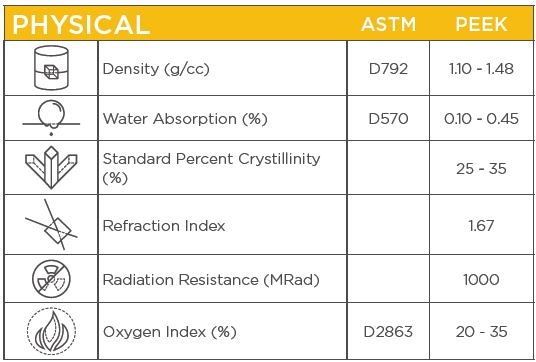

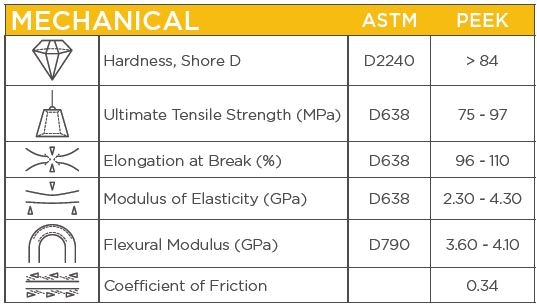

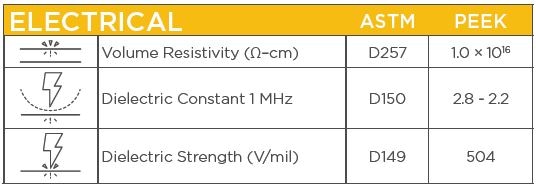

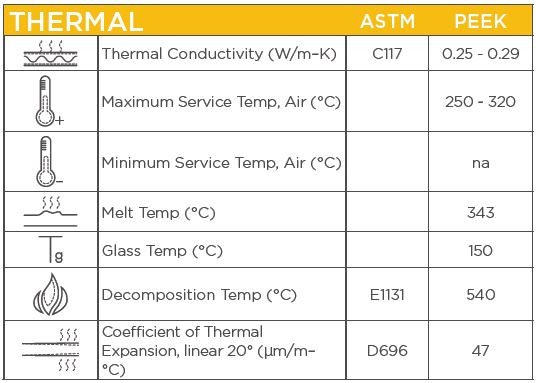

These tables are meant to serve as a general guideline only. Users have to assess the material to decide suitability for their own particular application.