Diverse product options

- Fiber optic coatings

- Furcation tubing / sheathing: standard and custom sizes / tolerances with coloring options are available

- Heat shrinks – PTFE, PEEKShrink®, FEP, ETFE, PTFE/FEP Dual-Shrink®, PFA

- Aeos® ePTFE Tubing – Zeus’ most flexible tubing

- Custom fillers – Glass additives improve bonding and control longitudinal change, barium offers visibility, and carbon fiber enhances crush resistance

- Secondary/value-add - Flaring, drilling, etching, and more

Dual-Shrink® Feature

The Dual-Shrink® heat shrink is a perfect example of Zeus’ protective insulation. It is capable of encapsulating and protecting cables, fiber optic housings, and connectors from high temperature or moisture.

Core Resins from Zeus

Zeus offers fiber optic coatings and extruded sheathings from polymers such as PEEK, ETFE, PFA, FEP, PVDF, and ECA. In the table given below, the key benefits of each extruded resin according to market are provided.

| ENERGY |

AEROSPACE |

SPECIAL TELECOM FIBER |

NUCLEAR |

AUTOMOTIVE |

MEDICAL |

PEEK

(260 °C) Abrasion Resistance, Mechanical Integrity, Thermal Stability

PFA

(-200 °C to 260 °C) Wide Temperature Stability, Low Coefficient of Thermal Expansion, Low Smoke/Toxicity |

PFA

(-200 °C to 260 °C) Wide Temperature Stability, Low Coefficient of Thermal Expansion, Low Smoke/Toxicity

FEP

(-200 °C to 204 °C) Low Water Absorption, Wide Temperature Stability, Low Coefficient of Friction |

FEP

(-200 °C to 200 °C)

&

ETFE

(-150 °C - 148 °C) Low Water Absorption, Wide Temperature Stability PVDF (150 °C) Chemical Resistant

PTFE |

ETFE

(148 °C) Radiation Resistance, Mechanical Integrity, Low Water Absorption

&

PVDF

(150 °C)

PEEK

(260 °C) Abrasion Resistance, Mechanical Integrity, Thermal Stability |

PTFE

(260 °C) Temperature Stability, Dry Lubrication, Low Coefficient of Friction, Low Water Absorption*

FEP

(-200 °C to 204 °C) Low Water Absorption, Wide Temperature Stability, Low Coefficient of Friction

NYLON |

PTFE

Low Coefficient of Friction, Class VI Approved

PEEK

Enhanced Pushability, Autoclave and Gamma Resistant, Class VI Approved

ETFE

Improved Strength and Performs well with ETO, Autoclave and Gamma Sterilization, Class VI Approved |

Fiber Optic Coatings

High performance protection for tough environments. Coatings protect fibers in situations that need mechanical strength, resistance to radiation/abrasion, and temperature stability.

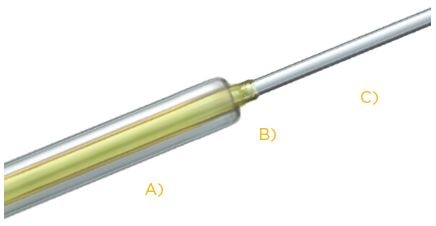

Polymer Coated Optical Fiber:

A) Polymer Protection — PEEK, ETFE, PVDF, PFA, FEP and more.

B) Primary Coating — Polyimide, Acrylic, etc.

C) Fused Silica Glass Core and Cladding

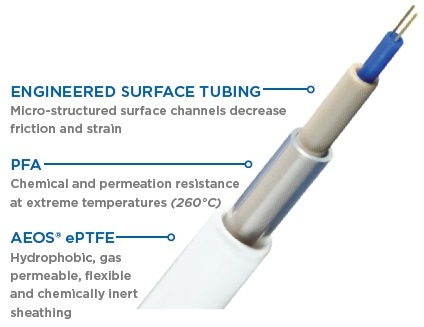

Assembly Aids for Sheathing

Making sheathing simple with extrusion solutions.

- Extrude sheathing over a number of wires or monofilament to serve as an assembly helps to pull fibers into sheathing. Eliminate flushing or feeding fibers into sheathing.

- Secondary/value-add services such as slitting, flaring, and drilling are available.

- Collaborate with the company’s extrusion engineers to spot the right extrusion solution for the project.

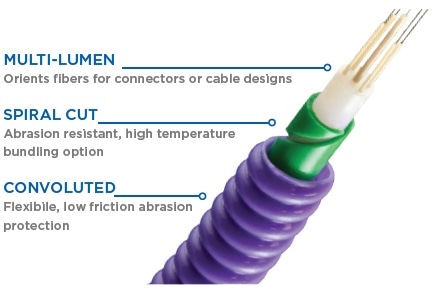

Specialized Extrusions

The company offers a wide range of shapes, sizes, colors, and custom profiles.

Focus on Orientation

Customers can ask about the company’s diverse catalog of multi-lumens — tubes with separate channels to orient fibers for cables and connectors. The company offers rectangular, square, and custom profile shapes in a wide range of resins and colors.