It is a continuous challenge for cleaving experts and novices to enhance quality, success rates, throughput, and targeting accuracy, and to achieve better productivity.

With these goals in mind, LatticeAx® systems were designed using smart mechanics together with microscope vision. The system’s engine is a 120-base MicrolineTM indent and cleaving system. With the 225 and 420 systems, the industrial and vision platforms are combined to achieve reproducibility and high cleaving accuracy without the complexity, sample restrictions, and cost of automated systems.

- Step 1. MicrolineTM indent. After placing the sample on the stage, held with vacuum, the cleave is initiated by the MicrolineTM indent (750 – 1000 µm long) created by the LatticeAx®. In order to achieve accuracy and edge quality, the indenter can be placed in ±5 µm steps and depth can be controlled by the calibrated clock dial knob.

- Step 2. Cleave. The sample is cleaved using 3pt cleaving. The fixed stress points designed into the LatticeAx® and the ability to control the pressure on the sample during the cleaving process allow a slow cleave, which results in superior quality cleaved edges.

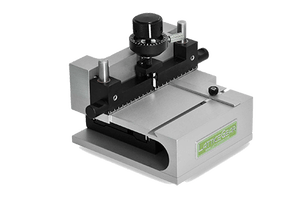

LatticeAx® 120

The patent pending LatticeAx® base platform is used by industrial laboratories and research institutions that require a cleaving tool, without excessive constraints with regards to sample type and sample dimensions, delivering superior quality results and a cost effective solution. Their users are experts in obtaining the maximum from the LatticeAx®120 and continue to find innovative uses for the instrument.

LatticeAx 225

Workflow speed, easy usage, and in certain cases accuracy are crucial when sample preparation procedures are integrated in a laboratory. The LatticeAx® 225 integrates an industrial platform with a digital microscope to the 120 base, transforming the 225 into a cleaving system. The microscope vision with the SW tools allow the micro-line indent to be fixed with ±20 µm targeting accuracy. The industrial installation enables multiple users to attain the same results daily.

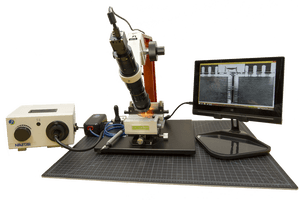

LatticeAx 420

The LatticeAx® 420 is utilized in R&D laboratories, failure analysis, cleanrooms and Nanofabrication facilities around the world. It is LatticeGear’s highest performance cleaving solution delivering both high quality reproducible results and high accuracy cleaving (HAC) results. It combines LatticeGear’s custom industrial platform and research grade vision package with precise focus control and 4-µm optical resolution to cleave with 10-µm accuracy in <5 minutes.

LatticeAx 120 from LatticeGear

LatticeAx 420 Components Overview