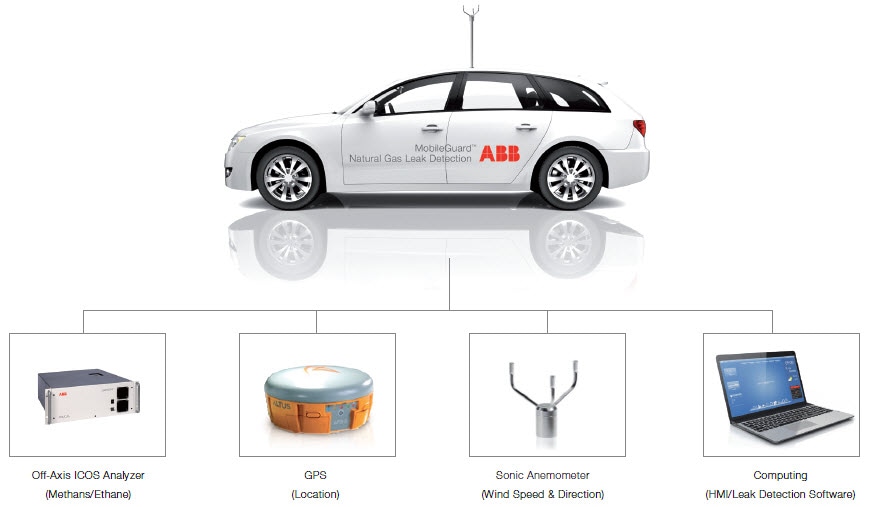

Find leaks fast

- Leak surveys can be carried out while driving at speeds up to 55 mph

- Both services and mains can be surveyed with the same drive by

- Only system that measures ethane and methane, hence it knows if it is naturally occurring methane or pipeline gas

Accurate

Find more leaks

- ABB’s patented OA-ICOS™ technology is the most reliable and sensitive gas sensing technology available

- Analyzer reports both ethane and methane in order to increase attribution rate and eliminate false positives

- Single parts per billion (ppb) sensitivity permits the system to detect leaks up to 600 feet away

- The system powers up and starts recording data within two minutes (competitive laser methods either need 30 – 45 minutes to warm up or are 1000X less sensitive)

- More up time – in contrast to other cavity based systems, ABB’s analyzer is very robust and can be completely serviced anywhere, anytime, by anyone in minutes

- Fastest operating speed of 5 Hz increases accuracy of estimation of plume size, leak size and distance to leak

Applications

MobileGuard Applications

- Construction verification

- Post disaster evaluation

- Survey mains and services

- Odor investigation

- Frost line evaluation

Advantages

The inherent advantages of OA-ICOS™ technology enable LGR trace gas and stable isotope analyzers to be the best choice, whatever the application.

- Wider Dynamic Range: OA-ICOS directly measures absorption instead of only a cavity decay time. It thus offers a linear response over a majorly wider dynamic range than standard CRDS (i.e. up to 100% mole fraction for a few gases).

- Best Performance: OA-ICOS analyzer performance does not depend on hyper-critical optical alignment, whereas older cavity-based techniques (for example, CRDS) need sub-nanometer optical component alignment. This makes these older techniques extremely vulnerable to degraded performance because of vibrations, changes in pressure and temperature, and small physical shocks.

- Parts-Per-Billion (ppb) Precision: OA-ICOS prevents the vulnerability and expense of a sub-nanometer opto-mechanical setup. This allows it to effortlessly deliver parts-per-billion precision (or better) rapidly and in an easy-to-use package.

- Field Serviced: OA-ICOS performance is orders of magnitude less sensitive to internal alignment, so the rugged instruments are reliable and robust. Moreover, designed with simplicity in mind, in the rare instance that repair is essential; LGR instruments could be effortlessly serviced on site by anyone.

- Lower Manufacturing Cost: OA-ICOS analyzer performance does not depend on hyper-critical optical alignment, whereas older, standard CRDS techniques need sub-nanometer optical component alignment. This demands the use of expensive electro-mechanical components and complex feedback loops including extremely time-consuming cleanroom assembly and elaborate testing.

- Minimal Downtime: OA-ICOS technology does not need ultra-precise optical alignment. This means that a minimally trained user can effortlessly remove a cavity mirror, if needed, and then clean and replace it within minutes, without creating any impact on performance or expensive returns to the factory.

- Better Value: OA-ICOS analyzer performance is totally unaffected by any minor moves in optical alignment. This enables the use of lower-cost, simpler components and fewer feedback control systems, besides simplifying the assembly process.