TALYS ADP300 is an affordable, high-performance wet bath monitoring analyzer that addresses the semiconductor industry's needs.

This dual channel analysis system is a state-of-the-art analyzer suited for batch-type, real-time, or single-wafer tool monitoring of wet etching, cleaning, or photoresist (PR) removal processes.

The TALYS ADP300 series is an evolution of the proven and well-known TALYS ASP300 single-channel analysis system, but with enhanced key performances and two simultaneous measurements.

It provides FPD, semiconductor, and solar-cell manufacturing with superior performance at an ideal price for stringent modern budgets.

This affordable, high-performance wet bath monitor enables real-time measurement at process temperature with a unique non-contact sampling system design allowing real-time dosing and end-of-bath alerts without delay due to sample conditioning.

Features and Benefits

- Measures two sampling points at the same time

- One single analyzer appropriate for measuring several chemistries with on-the-fly calibration switching

- Lowest ownership cost

- Low maintenance cost: Light source only needs a replacement once every five years

- Minimal footprint

- A unique sampling accessory (ClippIR+) allows non-intrusive measurements and system installation without modifying or stopping the tool

Flexibility and Performance

This reliable analyzer delivers the standard RCA cleaning suite bath prediction configuration. Its flexibility allows bath configuration modifications for monitoring chemistry from FPD, solar-cell, and semiconductor manufacturing.

TALYS performance allows equipment engineers and operators to minimize chemical usage and excursion events with real-time bath component predictions.

Data

The Patented ClippIR+

The ABB sample interface is a unique cell with no wetted parts and is simple to install. Just clip it onto an existing 1˝, 3⁄4˝, 1⁄2˝, or 3⁄8˝ PFA tube. The ClippIR is made of Teflon™ and coupled to TALYS through Teflon™ protected fiber-optic cables. The bath cannot be contaminated.

ABB’s ClippIR probe helps to simplify the installation as it is not necessary to shut down the tool, existing tubing does not need any modifications, and the no-wetted parts sampling avoids the risk of contamination. Contrary to titrators, there are no routine analyzer “zeroing” procedures nor reagent vessels to fill.

Image Credit: ABB Measurement & Analytics

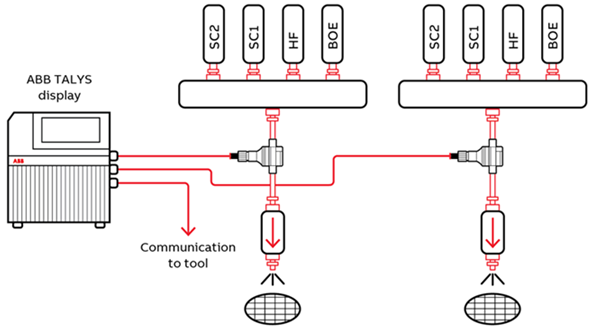

Multiple Chemistries at Two Sample Points

The TALYS ADP300 analyzer can rapidly measure multiple chemistries for two sample points simultaneously. The tool's automatic bath selection through Modbus TCP outputs allows real-time selection of the desired bath chemistry prediction routine.

While monitoring two or more bath chemistries on a tool, there is no requirement for a hardware change, manual intervention, or multiple analyzers, leading to substantial cost savings at the FAB. The ideal outcome would be a single analyzer measuring a delivery tube for SC1, SC2, BHF, BOE, DHF, and ST-250 without manual intervention, all controlled by the tool PC.

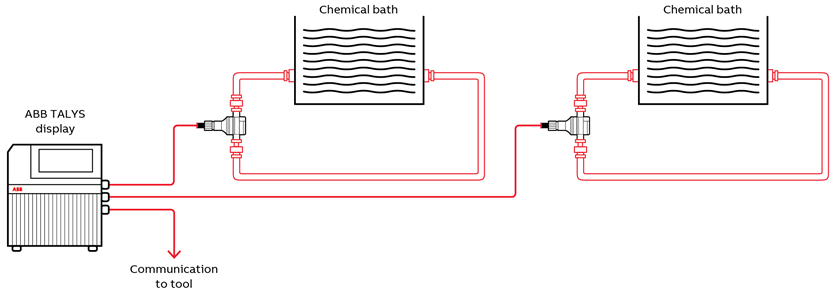

Monitoring a Recirculation Bath

Image Credit: ABB Measurement & Analytics

TALYS can be upgraded in the FAB through a file received by email if a technology update requires a new chemistry on the same production tool.

Monitoring On-the-Fly Chemical Usage

Image Credit: ABB Measurement & Analytics