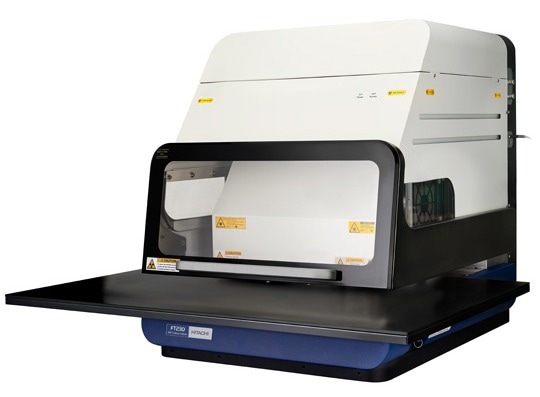

Hitachi’s FT200 series is a new ground-breaking X-Ray fluorescence (XRF) coating thickness analyzer that effectively ‘sets up’ itself, making it possible to analyze many more parts within a single shift.

Most of the user's time will be spent on the preparation and setup of the XRF analyzer, not the actual analysis. With increasingly tiny and complex components, tightening specifications, and the need for 100 % inspection, every second matters.

The new FT200 series from Hitachi cuts right to the heart of this problem. Every element of the FT200 series is designed to reduce the time it takes to complete an XRF measurement so that users can act on their results faster, reducing waste and increasing throughput. As a result, the XRF should no longer be the bottleneck in production.

From minute electronics components to large-scale plated parts, theFT200 serieshelps users achieve more in less time, making it easier to achieve 100 % inspection.

Why Select the FT200 series?

Automated Focusing with Auto Approach and Auto Focus

The instrument setup has been improved by providing users with a choice of two automated focusing options. The auto approach is used when a fixed working distance is preferred. With a single click, the instrument automatically moves the X-Ray tube to that distance.

Autofocus, sometimes called distance-independent measurement, allows the instrument to obtain accurate results even when the working distance changes. This can save a huge amount of time over a day of analysis, especially when measuring components that have complex geometries or different samples with features of varying heights.

Smart Recognition with Find My Part™

The FT200 series includes newly developed smart part recognition for a fast and foolproof analysis setup. Find My Part™ selects the right analytical routine for the part that is to be measured.

The XRF analyzer will make decisions about where and how to measure and send the results and reports where the user needs them. This is faster than a manual process, reducing the potential for user error and freeing up operators to perform other tasks. For new parts, it is simple to add them to the on-board library.

Smart and Simple Interface

The FT200 series is the first product to run Hitachi’s new FT Connect software. The most notable difference is the interface. Instead of a screen full of controls and options that the user needs to navigate, the FT Connect screen prioritizes the sample view and clear presentation of the analysis results. This makes it much easier to position parts correctly and act quickly on the results.

The routine measurement screen—where users spend nearly all their time with the XRF—shows only the controls needed to set up and start a measurement and evaluate results.

The FT200 series presents the largest in-software sample view in the industry. With the majority of the screen showing the part, operators can more easily view the features on the surface, helping them pinpoint the right area for analysis and making it much easier to navigate around the surface of the part.

In addition, the FT200 series comes with the option of a second, wide-view camera, to make it even easier and faster to find features on a large circuit board or metal-plated component. When the two cameras are used together, the user can quickly switch between measurement sites on a single part or between multiple parts in the chamber, without getting ‘lost’ in the details.

Data handling for Industry 4.0

FT Connect is built for data. For instant feedback and floor-level decision-making, the results are prominently displayed on the main measurement screen, enabling users to immediately take the appropriate action.

In addition, the FT200 series can send results in JSON format, ready for integration with the user's SCADA, QMS, MES, and ERP systems, integrating seamlessly with the wider production processes already in place.

Diagnostics and instrument health information can be shared with Hitachi’s technical support team over ExTOPE Connect—Hitachi’s cloud-based data management and storage service—to help keep users of the FT200 series operating with maximum reliability and efficiency.

The FT Connect software includes powerful reporting features that allow users to generate customizable reports for internal or external customers. Data can also be exported in JSON or spreadsheet format to local or networked drives for close inspection by the user's analytical experts.

Benchtop XRF analyzers in the FT200 Series have been engineered to significantly cut down on measurement time. Hitachi’s engineers have developed a range of innovative analyzers that essentially “set up” themselves, allowing for the analysis of a multitude of parts in a single shift. They realized that the most time is spent on sample preparation and measurement protocol selection.

Image Credit: Hitachi High-Tech Analytical Science

The FT200 series analyzers are unique because of their automation and cutting-edge software. All the operator needs to do is load the sample and verify the part, and the instrument will take care of the rest, thanks to smart recognition modules like Find My Part™.

It will locate the appropriate measurement places on the user's part, even on large substrates, choose the appropriate analysis software, and submit the data to the quality system. Time and human error are decreased, and users can perform more analyses in less time, making 100 % inspection far more practical in a busy manufacturing setting.

Product Highlights

Every aspect of the FT200 series has been engineered to significantly minimize analysis time.

- Sample loading time is decreased via automated focusing

- The entire measurement procedure is automatically set by Find My Part™ smart recognition

- Sample view is displayed for optimal visibility across a significant portion of the screen

- Self-checking diagnostics verify the device’s stability and overall health

- Exports data and integrates seamlessly with other software

- Non-specialists can easily utilize it with its intuitive user interface

- Strong enough to measure the substrate and up to four layers at once

- Long-lasting in a demanding laboratory or industrial settings

- Meets DIN ISO 3497 and ASTM B568 requirements

- Aids in fulfilling ENIG (IPC-4552B), ENEPIG (IPC-4556), immersion Sn (IPC-4554), and immersion Ag (IPC-4553A)

Source: Hitachi High-Tech Analytical Science

| |

FT210 benchtop XRF analyzer |

FT230 benchtop XRF analyzer |

| Element range |

Ti (22) - U (92) |

Al (13) - U (92) |

| Detector |

Proportional counter |

Silicon drift detector (SDD) |

| Chamber design |

Slotted or closed |

Slotted or closed |

| XY stage design |

Motorized or fixed |

Motorized or fixed |

| XY stage travel |

250 x 200 mm |

250 x 200 mm |

| Motorized Z-axis travel |

205 mm |

205 mm |

| Largest sample size |

500 x 400 x 150 mm |

500 x 400 x 150 mm |

| Number of collimators |

4 |

4 |

| Focus laser |

Included as standard |

Included as standard |

| Automated focus |

Option |

Option |

| Wide-view camera |

Option |

Option |

| Distance-independent measurement |

Option |

Option |

| Find My Part™ smart recognition |

Option |

Option |

| Coatings analysis |

✓ |

✓ |

| RoHS screening |

n/a |

✓ |

| Software |

FT Connect |

FT Connect |