The Next Generation 6800 Series universal testing systems from Instron – USA are available in capacity ranging from 500 N to 300 kN. These systems are capable of providing outstanding performance together with unmatched reliability and accuracy.

The 6800 Series provides ultimate flexibility for different testing requirements as it offers up to 5 kHz data acquisition and 0.5% accuracy down to 1/1000th of load cell capacity.

Instron 6800 Series Universal Testing Systems

Available Models—0.02 N (2 gf) to 50 kN Force Capacities

Low-Force Testing Systems

The 6800 single column series offers up to 5 kN capacity available in standard as well as extra height options for low-force applications.

6800 Series single-column universal testing system.

Mid-Range Testing Systems

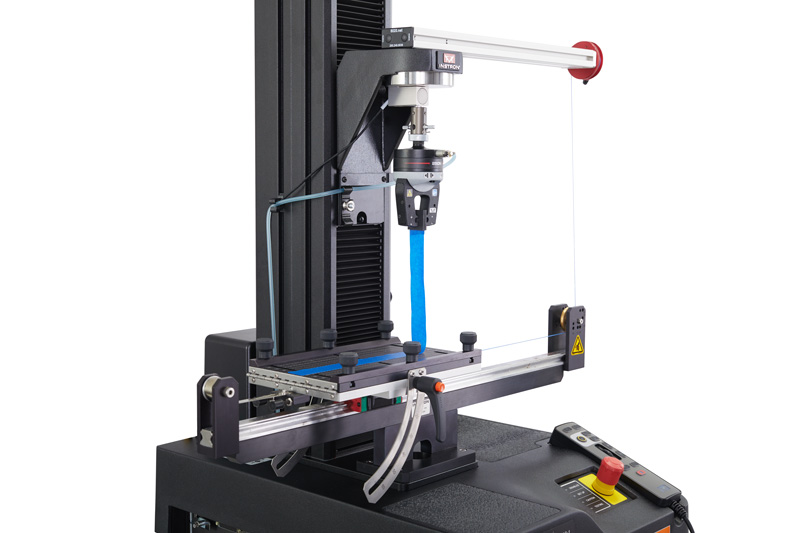

The 6800 dual column table model series offers up to 50 kN capacity available in standard as well as extra height options for higher force applications.

6800 Series dual-column universal testing system.

Any Application

The 6800 series Universal Testing Machines have been specially designed to execute tensile, flex, peel, compression, friction, shear tests, puncture, and more. These systems can be used with hundreds of fixtures and grips available in Instron’s extensive accessories catalog, with particular configurations designed to carry out the most common tests specific to the automotive, consumer electronics, biomedical, and raw materials industries.

Bluehill® Universal.

Simpler—Powered by Bluehill® Universal

Instron’s Bluehill® Universal software powers the 6800 Series universal testing systems. Bluehill® Universal is integrated with easy-to-understand icons and workflows and this indeed makes it easy to train users and set up tests, enabling them to maximize lab efficiency while minimizing expensive errors.

QuickTest

When users need quick results, QuickTest enables them to enter a few simple parameters and then run their test within just a few seconds.

Pre-Loaded Templates

Bluehill® Universal is available with a wide collection of pre-configured methods for some of the most regularly used ISO, EN, and ASTM standards. All these methods are packaged in specific modules that suit users’ testing applications.

Workflow

Users can be guided via the complete testing process with step-by-step instructions, guaranteeing that their tests remain simple, error-free, and repeatable. Users can also effortlessly customize the prompts with their own images and text.

Auto Positioning

Auto Positioning helps in saving the exact fixture separation starting location for every single test method. This guarantees that all operators run each test in the same, exact manner across all shifts daily.

Auto positioning for the 6800 Series universal testing system.

TestProfiler

TestProfiler helps in building simple cyclic tests that include holds, ramps, and triangle waves. Conditional logic permits users to develop looping patterns that help in imitating real-life situations within tests.

TestProfiler in Bluehill Universal materials testing software.

Smarter

Advanced Performance and Applications

The 6800 Series can be extended to encompass Digital Input/Output Channels and up to 11 Sensor Conditioning Modules to guarantee compatibility with innovative accessories and external devices. While testing on a 6800 Series frame, users will be able to capture synchronized data at a speed of up to 5 kHz along with modifiable bandwidth so that they do not miss a test event.

Operator protect.

Safer—Safety Without Sacrificing Throughput

Operator Protect

The 6800 Series is based on Instron’s patent-pending Operator Protect architecture. A smart workflow helps in keeping operators and equipment safer by managing system status starting from setup to test completion.

Built-In Safety Coaching

With the 6800 series, users will be able to get a clear visual feedback regarding system status continuously. Users will be able to effortlessly comprehend when the system is in a safe set up mode, and will be clearly prompted to exit the test space after these safety limits are removed.

Smart-Close Air Kit

Finger pinch threats from pneumatic grips are minimized via lower grip-closing pressure and controlled speed during the set-up phase of a test.

All-New Handset

The 6800 handset is designed to bring system controls closer than ever before because of its all-new ergonomic handset directly mounted to the frame. This handset can be used by operators in the mounted position or it can also be detached from its dock.

6800 Series handset.

Customizable Soft Keys

With two user-defined “Soft Key” buttons, the operator can start a wide range of commands. The Soft Keys can be defined for each method, allowing each test to be customized.

Virtual Interlock

Instron’s patent-pending system architecture restricts the machine’s movement to prevent unintentional movement of the crosshead.

Variable Speed Jog

When the system is in the set-up mode, it will default to a safe speed suitable for an operator to comfortably work in the test space.

Precise Positioning

The Fine Position adjustment thumbwheel with tactile feedback permits precision positioning of the crosshead in increments of 4 μm when carrying out sensitive testing.

Specimen Protect

Specimen Protect prevents the application of unwanted forces to the specimen by automatically making adequate adjustments to the crosshead, thus shielding the valued specimen from any type of harm.

6800 Series dual-column testing system.

Built to Last—Protecting User’s Investment

Collision Mitigation

Decreases damage to delicate specimens and equipment by halting the crosshead if force is identified during a jog or upon return.

Load Cell Overload Protection

The 6800 series is capable of automatically stopping when the load cell touches maximum capacity. This prevents damage to the system, load cell, and accessories.

2580 Series Load Cells

The 2580 Series load cells have been specially designed for use with 6800 testing systems, offering outstanding performance with the potential to measure forces as low as 1/1000th of the force capacity to a precision of ±0.5% of reading.

The load cells designed and manufactured by Instron can withstand loads up to 150% of their force capacity without causing any harm, and 300% without mechanical failure. They can be easily used because of automatic transducer recognition and electrical calibration.

Built for Durability

Stiff Frames for High-Strength Materials

The 6800 has been exclusively built for superior performance. It includes a thick crosshead and base beam, precision ball screws, pre-loaded bearings, and low-stretch drive belts to guarantee longevity and superior performance.

6800 Series dual-column internal components.

Precision Guidance for Alignment and Bending

When carrying out a uniaxial test, precise stress and strain results can only be obtained using a system that comprises sturdy, precise guidance columns that guarantee minimal specimen bending under load.

Larger Motors for Better Reliability

The 6800 load frames employ powerful motors with reserve capacity that enables faster rates of acceleration. Maintenance-free brushless AC servomotors allow creep, cyclic, and relaxation testing for up to 10 days (up to 1 Hz at 25 °C).

Servo-Controlled Drive System

Besides having a powerful motor, the 6800 drive systems also include a robust steel casting with a dual-belt drive system. In contrast to those systems that use gear-reducers, which develop backlash and lower drive system stiffness, the dual-belt systems offer synchronous movements of the ball screws, eradicating crosshead tilt and supporting system alignment.

Instron® 68FM Universal Testing Systems | Advanced Performance for High-Force Testing