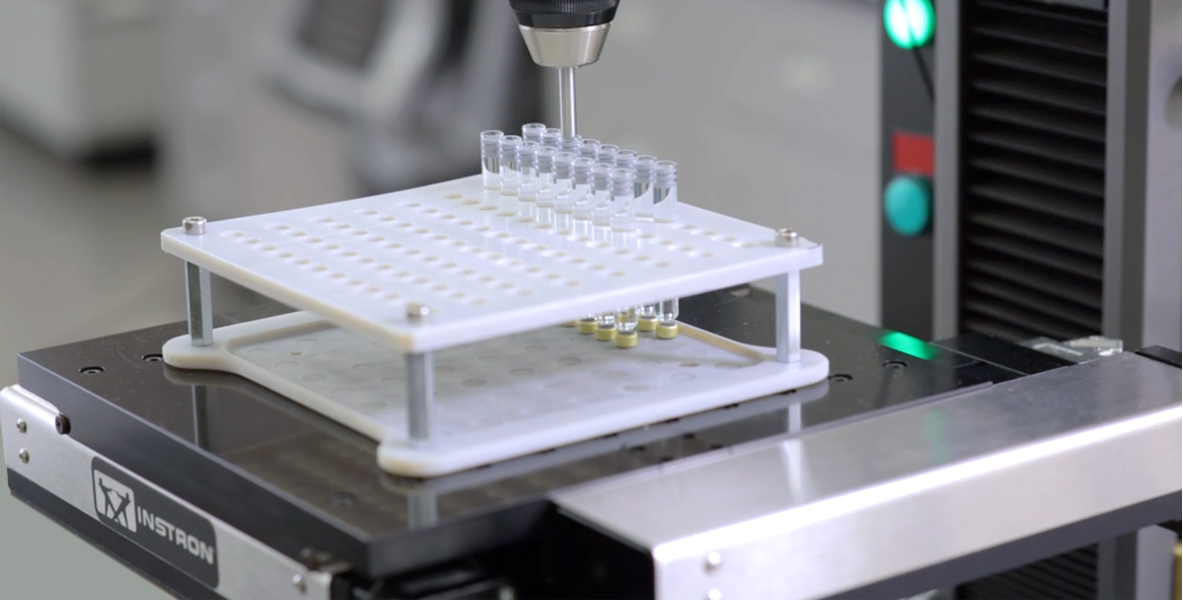

The AT2 Automated XY Stage from Instron can be integrated with any existing or new 5900 and 6800 Series universal testing systems to automate tensile, compression, and flexure testing of components or devices with several test points, or multiple components with repetitive test points.

Such systems are extensively used in the electronics and biomedical sectors to test an extensive range of components, devices, and materials.

Image Credit: Instron - USA

In industries like the medical device sector, several components, end products, or sub-assemblies include several elements, such as leads, that must be tested independently of one another.

The Automated XY Stage System enables the specimen to be automatically repositioned so that every element can be tested without the need to re-install the specimen.

Furthermore, when the first alignment is crucial for successful testing, the XY Stage Testing System offers the potential for rapid and repeatable results, such as applications like insertion and withdrawal testing or precision bend testing. The flexibility of the Automated XY Stage enables it to adapt to test several components, devices, or specimens.

Mini Keyboard Test Using AT2 Automated XY Stage

Video Credit: Instron - USA

Application Range

- Biomedical: springs, pharmaceutical pills, vials, and syringes

- Type of loading: flex, tensile, compression

- Electronics: small electronics, touch-capable displays, keypads

Specifications

Source: Instron - USA

| . |

. |

| Maximum Stage Load Capacity |

2 kN |

| XY Stage Travel (Option 1) |

300 x 150 mm |

| XY Stage Travel (Option 2) |

150 x 150 mm |

| Stage Speed |

25 mm/sec |

| View Full Specifications |

Download Brochure |

Automation Advantages

Increased Throughput

Several specimens can be tested by an automated testing system without the need for operator intervention. This decreases the entire test time for a sample, thus enabling data utilized for product production and development to be offered more rapidly.

Image Credit: Instron - USA

Increased Repeatability

Automated systems decrease operator impact on test results, thereby enabling more repeatable and consistent results. This is particularly beneficial for organizations where multiple operators work in multiple labs.

Better Use of Skilled Labor

An automated testing system operates without operator supervision, thus producing results while skilled operators enhance their efficiency by concentrating on other essential tasks.

Improved Safety and Ergonomics

Automated testing reduces repetitive motion and decreases the amount of physical interaction with the testing system, thus minimizing injuries to the operators.

Image Credit: Instron - USA

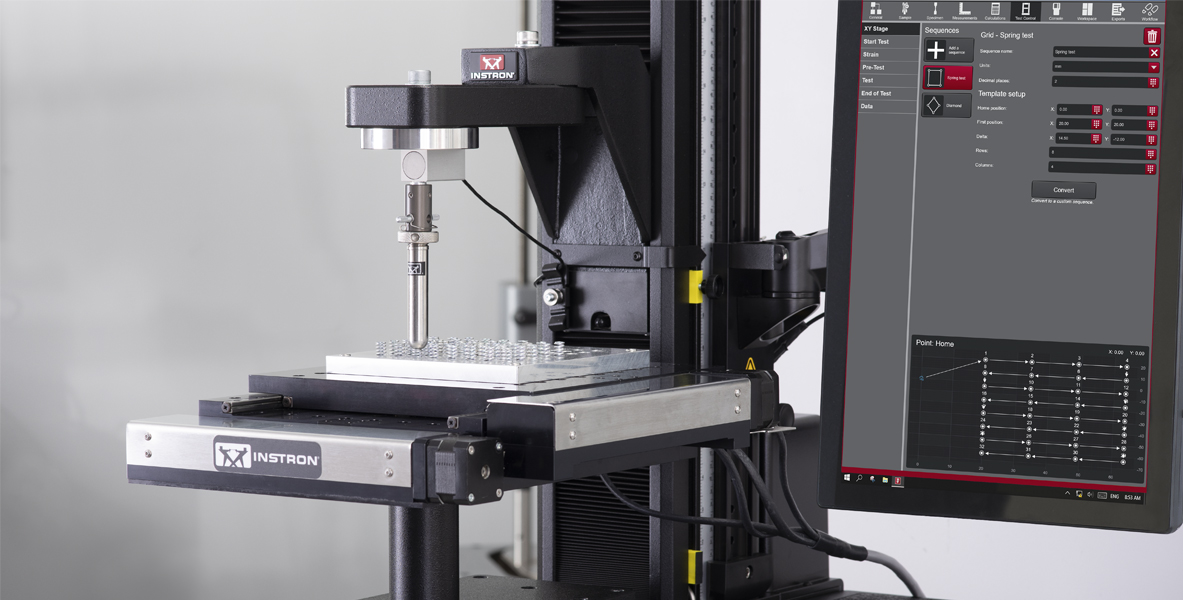

Bluehill® Universal Integration

Seamless Control of the XY Stage Movements

XY Stage Movement

The Bluehill® Universal can be used to easily shift the XY stage into several positions for specimen configuration and test location identification.

AT2 Automated XY Stage Movement in Bluehill® Universal Software

Video Credit: Instron - USA

Sequence Builder

Users can develop a series of test locations in Bluehill® Universal by making use of grid or diamond patterns, or make a custom sequence to test components in which the distance between the test locations differ.

Building Sequences with the AT2 Automated XY Stage

Video Credit: Instron - USA

Example Applications

Automated XY Stage for Button Testing

Button testing. Video Credit: Instron - USA

XY Stage for Compression Testing on Electronic Device Display Screen

Compression testing of electronic displays. Video Credit: Instron - USA