Better chemical synthesis for more successful experiments. Replace the round bottom flask.

Chemical synthesis reactors are alternatives to ice baths, glass reactors, oil baths, and jacketed lab reactors. EasyMax and OptiMax chemical synthesis reactors are well established in almost all laboratories in the pharmaceutical and chemical industries.

Image Credit: METTLER TOLEDO

The advanced synthesis reactors permit accurate and precise management of reaction parameters, including dosing, stirring, sampling, and temperature control, allowing every chemist to carry out reproducible reactions. Experiments can be performed unattended 24/7, and all data are automatically saved and can be visualized and controlled either from the computer or touchscreen.

Chemical synthesis reactors reinvent the way the researchers work, thereby allowing them to produce more data per experiment to provide life-changing products quicker and more efficiently.

Explore a Wide Range of Operating Conditions

Flexible, safe, and intuitive chemical reactors

EasyMax 102 Basic and EasyMax 402 Basic chemical synthesis reactors from METTLER TOLEDO enable chemists to find new synthetic pathways and create elegant chemistry by investigating reaction conditions from −40 °C to 180 °C without an oil bath, ice bath, heating mantle, or cryostat. Reactions can be carried out from 1 to 400 mL, controlling reaction factors such as temperature, pH, or dosing accurately so that ideal conditions can be swiftly identified.

Image Credit: METTLER TOLEDO

24-Hour Unattended Experimentation

Optimize innovative reactions

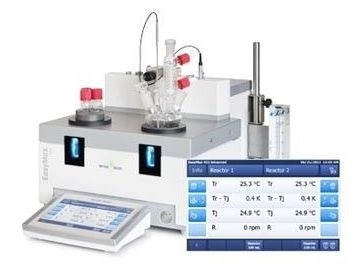

EasyMax 102 Advanced and EasyMax 402 Advanced chemical synthesis reactors help researchers quickly investigate reaction parameters, even under challenging conditions. Simplification of the user interaction enables more successful experiments to be carried out and the design of experiment studies (DoE) to be finished quickly.

Image Credit: METTLER TOLEDO

Non-scalable reaction parameters and ideal conditions can then be identified confidently. Reactions can take place totally unattended, day or night, allowing researchers to synthesize new compounds, remove non-viable candidates early, and safely enhance the reaction in a short span of time.

Ensure Safe, Robust, and Scalable Processes

Characterize and optimize during scale-up

OptiMax lab reactor systems are built to enhance process conditions in the liter scale and provide researchers with the chance to make knowledgeable and trusted decisions. The small footprint, robust heating/cooling system, and ability to safely carry out reactions unattended make OptiMax a suitable tool for process development.

Image Credit: METTLER TOLEDO

The optional upgrade to a Reaction Calorimeter delivers vital thermodynamic data, helping researchers recognize unsafe reaction conditions when scaling up.

Capture and Report all Chemistry Data

Make better and faster decisions

EasyMax and OptiMax chemical synthesis reactors combine effortlessly with the real-time in situ Process Analytical Technology (PAT) probes, such as ReactIR, EasySampler, ParticleTrack, or ParticleView. All data and events are saved and reports are generated in a single click. Due to the complete understanding of any process scale-up problems, researchers can deliver grams or kilograms of materials quicker and safer.

Image Credit: METTLER TOLEDO

Automated Chemical Synthesis Reactors in Journal Publications

Listed below is a selection of publications about chemical synthesis reactors:

- Peplow, M. – Automation for the people: Training a new generation of chemists in data-driven synthesis, C&EN, October 27, 2019, Vol. 97, Issue 42.

- Mills J. E. – Chemical Process Research, ACS Symposium Series, 2003, Chapter 6, pp 87–109.

- Owen et al. − Organic Process Research & Development, 2001, 5, pp. 308−323.

- Hwang R., Noack R. M. − International Journal of Experimental Design and Process Optimisation, 2011, Vol.2, No.1, pp. 58−65.

- Guidance for Industry, Q8 (R2) Pharmaceutical Development, U.S. Department of Health and Human Services, Food and Drug Administration, November 2009, Revision 2.

- Charles D. Papageorgiou et al. Development and Scale-up of an Efficient Miyaura Borylation Process Using Tetrahydroxydiboron. Organic Process Research & Development 22.1, 2017, 65–74.

- Thomas, et al. Scalable and Selective Preparation of 3, 3′, 5, 5′-Tetramethyl-2, 2′-biphenol. Organic Process Research & Development 21.1, 2017: 79–84.

- Buetti-Weekly, Michele T., et al. Development of a safe and scalable process for the preparation of allyl glyoxalate. Organic Process Research & Development 22.1, 2018: 82–90.

- Yang, et al. Evaluation of Potential Safety Hazards Associated with the Suzuki−Miyaura Cross-Coupling of Aryl Bromides with Vinylboron Species. Org. Process Res. Dev. 2018, 22, 351−359.

- Kinetics of a C-H Activation Reaction, Sampling Air-Sensitive Reactions, METTLER TOLEDO Application Note based on studies by Brian Vanderplas and David Place, Pfizer.