Simple and Trustworthy Boiling Point Measurements at Your Fingertips

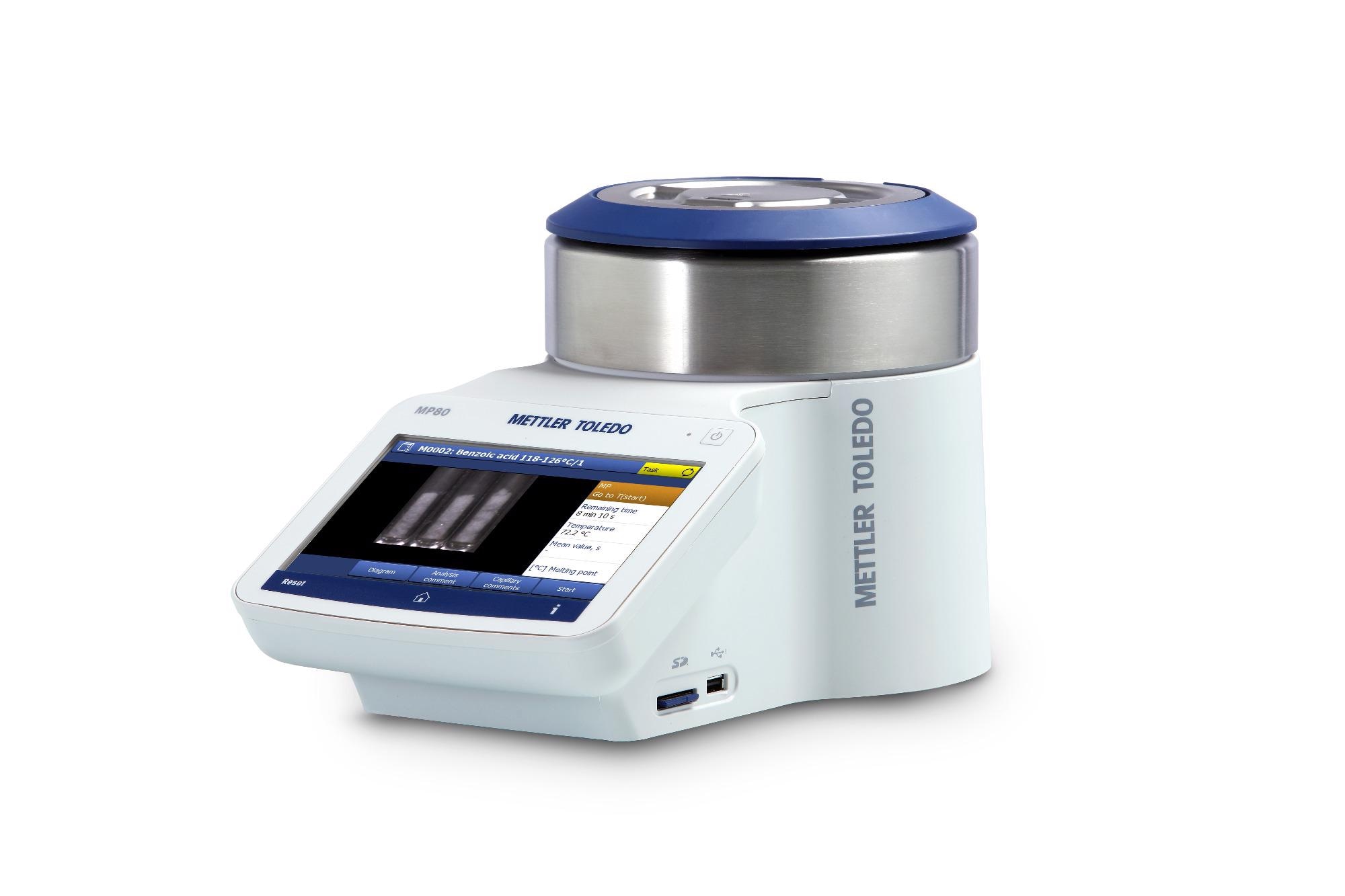

The MP80 Melting Point System from METTLER TOLEDO has been optimized for a variety of tasks. It provides One Click™ boiling point, melting point, slip melting point, and cloud point.

The Melting Point Excellence System also offers the following benefits:

- Color video recording

- Improved export possibilities

- Accessories for sample preparation

- Can store large results

Specifications

Source: METTLER TOLEDO

| . |

. |

| Temperature Range |

RT – 350 °C |

| Number of One Clicks™ |

12 Per User |

| Application Type |

Melting Point; Boiling Point; Cloud Point; Slip Melting Point |

| Data Export |

To SD Card or PC |

| Heating Rate (/min) |

0.1 °C – 20 °C |

| Cooling time (300 °C to 50 °C) |

5.5 min |

| Heating time (50 °C to 300 °C) (min) |

4 |

| Number of Capillaries (2) |

3 Melting Point Capillaries; 2 Slip Melting Point Capillaries; 2 Boiling Point Capillaries; 2 Cloud Point Capillaries |

| PDF Reports |

Yes |

| Stored Methods |

20 |

| Stored Results |

50 |

| User Management |

Multiple Users; Password Protection; Protection of Settings |

| Substances in database |

6 |

| Video |

color, 300 minutes |

| Material Number(s) |

30321331 |

Thermal Values at a Glance

Boiling, melting, slip melting, and cloud point measurements and assessments are carried out in a fully automated manner, without the need for constant visual observation. The results of the boiling point are automatically rectified to normal pressure through a built-in pressure sensor.

Image Credit: METTLER TOLEDO

Identity and Purity

The instrument offers precise and rapid techniques that enable automatic evaluation of properties. Users can perform checks and quality control (QC) of materials with defined properties.

Image Credit: METTLER TOLEDO

Maximum Efficiency

Concurrent measurement of up to three samples for melting range and melting point, or up to two samples for boiling, slip, and cloud melting points, saves precious time and effort. Brief cooling and heating times enable users to perform more analyses in a shorter duration.

Image Credit: METTLER TOLEDO

Video is Recorded

Visual data is stored for unsupervised measurements. The high-resolution color videos can be easily replayed on the instrument at any time, enabling the validation of the measurement integrity.

Image Credit: METTLER TOLEDO