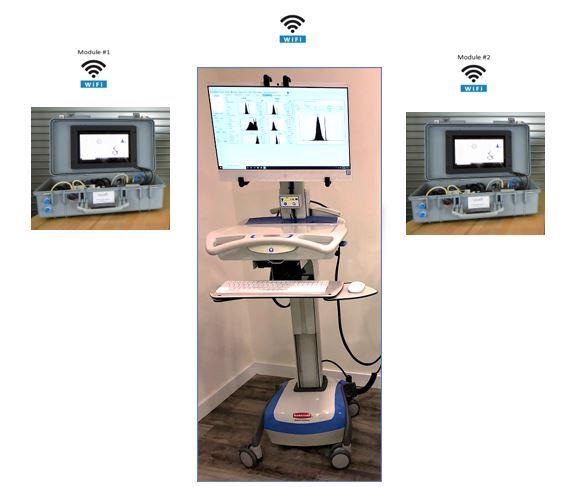

The Pi PMS from Vision Analytical is a portable on-line shape analyzer system that can act as a dedicated or temporary system to track size and shape in real-time.

Fundamentally, the system is a fusion of various Pi Sentinel PRO instruments, the most advanced dynamic image analyzers integrated into analysis modules and manipulated by a Master computer into a portable battery-operated control unit.

This system is ideal for applications where tracking not only the diameter but also the shape of raw materials is essential for on-line processes. In several pharmaceutical and industrial processes, it is vital to ensure the same morphology to guarantee the efficacy of the final product.

It is essential to make use of a high-resolution analytical tool that can provide as much data as possible regarding the formation of crystals over time. The Pi PMS has been developed particularly to work where raw material manufacturing processes need real-time feedback to make crucial process decisions.

Image Credit: Vision Analytical

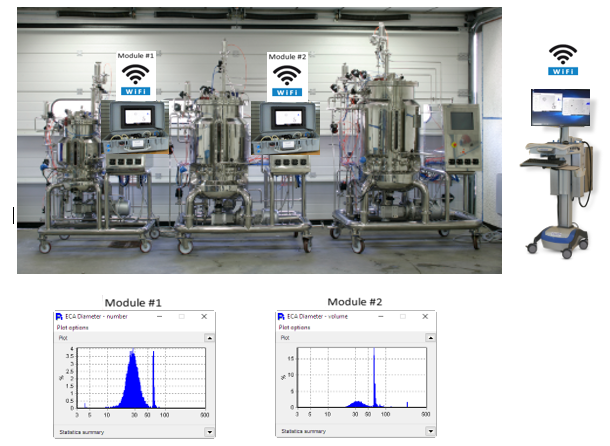

The Pi PMS’ Analysis Modules have been specifically designed to function where raw material manufacturing processes take place and need real-time feedback to make crucial process decisions.

That is, the sample for analysis is taken directly by the Pi PMS from the reactor or process. The raw material analysis is carried out “on-line,” close to the reactors and without any interruption or considerable modification of customer resources. Once the analysis is over, the Analysis Modules can be detached from that group of reactors and then linked to a different group.

Image Credit: Vision Analytical

A master touchscreen all-in-one computer located on the top section of the control unit monitors the performance of two or more instruments at the same time, through a wireless remote-control application to track the raw material analysis directly over the process or reactors.

A strong battery powers the system and includes a smart controller or charger to maintain the battery completely charged all the time. Thus, a continuous duty cycle of 24/7/365 is anticipated.

Remote troubleshooting can be performed only if the process owner gives access to the system (a randomly generated password that is valid only once).

Control Unit

Upper Section

The upper section includes a touchscreen all-in-one computer that serves as a master computer and a display. The computer regulates both the wireless modules through remote-control application software.

Image Credit: Vision Analytical

Lower Section

The lower section is provided with the battery including the smart controller or charger, as well as the inverter to offer power to the upper section of the tower.

Image Credit: Vision Analytical

Wireless Analysis Module

The wireless module includes a Pi Sentinel PRO instrument (modular version) and a Microsoft Surface PRO 4 computer. This enables autonomous tracking of a process while being monitored and regulated by the master computer.

Image Credit: Vision Analytical