PowderPro A1 from Bettersize Instruments automatically measures powder characteristics like Angle of Spatula, Angle of Fall, Angle of Repose, Tapped Density and Bulk Density for a range of powder materials. PowderPro A1 employs the automated imaging technology controlled with Bettersize app, which makes it easy and convenient to operate on any android, tablet and PC system. The combination of automated imaging technology and Bettersize app makes PowderPro A1 an important tool to research and evaluate powder materials.

PowderPro A1 Overview | Automatic Powder Characteristics Tester

Powder Characteristics Tester by Fully Automatic Analysis

The physical characteristics of a powder pile are very essential and must be quantified; the fundamental physical properties of powdered materials are practically crucial in powder production, processing, transportation, storage and other applications.

PowderPro A1 is essentially utilized for the analysis of powder physical properties by measuring angle of spatula, angle of repose and fall, bulk density, tapped density, etc. PowderPro A1 was designed to achieve simple, quick, precise and scientific test outcomes for the physical properties of all such powders.

Features

Listed below are the features and benefits of PowderPro A1 powder physical characteristics tester

Measured and Calculated Parameters

PowderPro A1 measures automatically:

- Angle of fall

- Angle and repose

- Angle of spatula

- Bulk density

- Tapped density

- Voidage

- Cohesion

- Dispersibility

PowderPro A1 calculates automatically:

- Uniformity

- Sieve size

- Angle of difference

- Compressibility

- Carr Floodability index

- Carr Flowability index

Measure Angles with Image Method

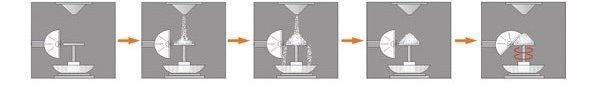

Parameters like angle of spatula, angle of fall and angle of repose are achieved in a quick and simple way with good repeatability and high accuracy using the special image recognition and processing technology.

Patented Rotary Vibration Technology

Users can guarantee smooth surface of the powder and enhance measurement precision.

Automatic Control Technology

Completely automatic PC or mobile control guarantees simple usage and operation. Precise and reliable test results are achieved by SOP mode for standardized testing process.

Conformity

- ASTM D6393-08/D6393-14

- EP7.0 07/2010:20934E

- USP32-NF27<616>

- ISO 3953:1993

Data Communication

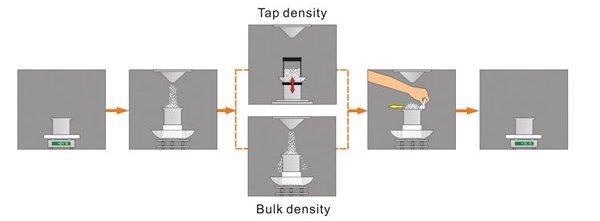

An electronic scale is linked to the instrument and the weight data is transferred automatically to the system for calculation of results and data processing.

Advanced Technology of Tapped Density

The tapped density is obtained via the perfect combination of variable frequency and rotary vibration technology. The vibration frequency of 50 to 300 times per minute can be constantly adjusted; vibration amplitude of 3 or 14 mm can be chosen. When vibration occurs, the cylinder is in an even rotation state, which ensures the horizontal powder surface and enhances the reading precision.

Measure Angle of Repose

Image Credit: Bettersize Instruments Ltd.

Measure Bulk Density and Tapped Density

Image Credit: Bettersize Instruments Ltd.

Applications:

- Pharmaceuticals

- Toners

- Battery materials

- Powder detergents

- Metal powders

- Building materials

- Ceramics

- Soils & sediments

- Oils & petrochemicals