The PlasmaPro 100 PECVD system from Oxford Instruments has been specifically designed to produce high-quality films that exhibit outstanding uniformity and control of film properties like wet chemical etch rate, refractive index, stress, and electrical characteristics.

The advanced Plasma Enhanced CVD system is ideal for the passivation of dielectric films (for example, SixNy, SiO2), amorphous silicon, silicon carbide, hard mask deposition, and anti-reflective coatings.

- High-quality films, high throughput, and outstanding uniformity

- High-density plasma and low-pressure deposition

- Compatible with wafer sizes up to 200 mm

- In-situ chamber cleaning and end-pointing

- Simple serviceability and low cost of ownership

- Outstanding control of refractive index and stress

- Quick change between wafer sizes

- Resistive heated electrodes with capability ranging from 400 °C to 1200 °C

Overview

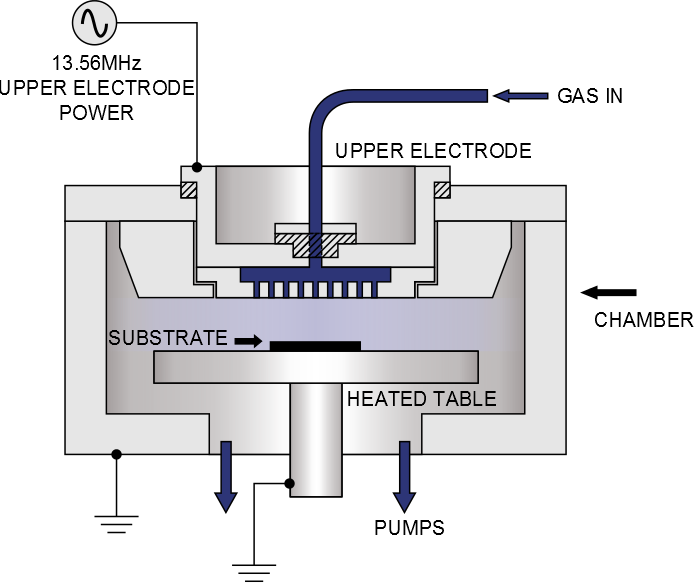

PlasmaPro 100 PECVD offers outstanding low particle generation and conformal deposition as a result of the electrode temperature uniformity and shower head design in the electrode, thereby enabling RF energy to produce the plasma.

High deposition rates have been provided by the high-energy reactive species of plasma to obtain the preferred thickness of the substrate while low pressure is retained. Its dual frequency 13.56 MHz and 100 KHz power employed to the upper electrode allows for film densification and stress control.

Features

- High pumping capacity provides extensive process pressure window

- Delivers reactive species to the substrate with a uniform high conductance path via the chamber, which enables a high gas flow to be utilized while retaining low pressure

- RF-powered showerhead with improved gas delivery offers even plasma processing with LF/RF switching, enabling accurate control of film stress

Applications

- High-quality PECVD of silicon dioxide and silicon nitride available for photonics, passivation, dielectric layers, and several other uses

- Amorphous silicon (a-Si:H) and poly-Si

- Silicon Carbide (SiC)

- Hard mask deposition and etch could be performed for high-brightness LED production

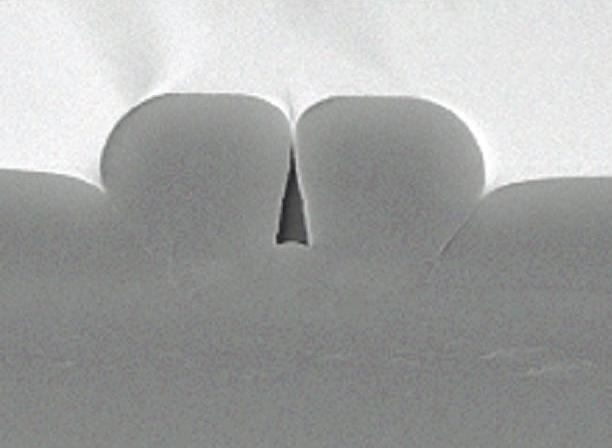

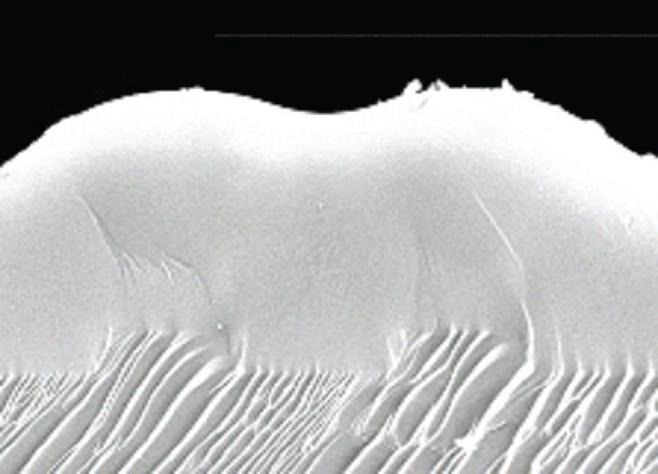

High rate SiO2 PECVD. Image Credit: Oxford Instruments Plasma Technology

High rate SiO2 PECVD. Image Credit: Oxford Instruments Plasma Technology

Specifications

- Clustering can be done for up to four process modules

- Resistive heated electrodes: ranges up to 400 °C or 1200 °C

- Precursor delivery option:

- Liquid or solid precursors available

- Carrier gas assist, vapor draw, or bubbling modes

- Can be heated up to 70 °C

- Uses standard canisters from all significant precursor suppliers

Image Credit: Oxford Instruments–Plasma Technology