PTIQ is the latest intelligent software solution for PlasmaPro and Atomfab processing equipment.

Highlights

- Optimize system and process performance

- User-friendly design

- Excellent level of responsive system control

Intelligent Software. Powerful Solutions

PTIQ Software – Oxford Instruments Plasma Technology

Video Credit: Oxford Instruments Plasma Technology

For systems using Plasma Technology, the most recent intelligent software solution is PTIQ. It offers a high degree of system management, together with effective scheduling and intelligent reporting features, which open up new opportunities for increased processing effectiveness and flexible workflows.

There are many tiers of PTIQ Software available to fit facility requirements, and it improves system and process performance in the Lab and Fab.

The Benefits of Using PTIQ

User-Friendly Design

- For optimum user productivity, the “at a glance” design makes the information and control more accessible with fewer clicks.

- To better comprehend the system architecture, process engineers can describe system components at a high level, or maintenance engineers can use functional diagrams in the LabView style.

- Color scheme with high contrast intended for use in typical yellow light manufacturing settings.

- Designed with touchscreen use in mind, as requested by the users.

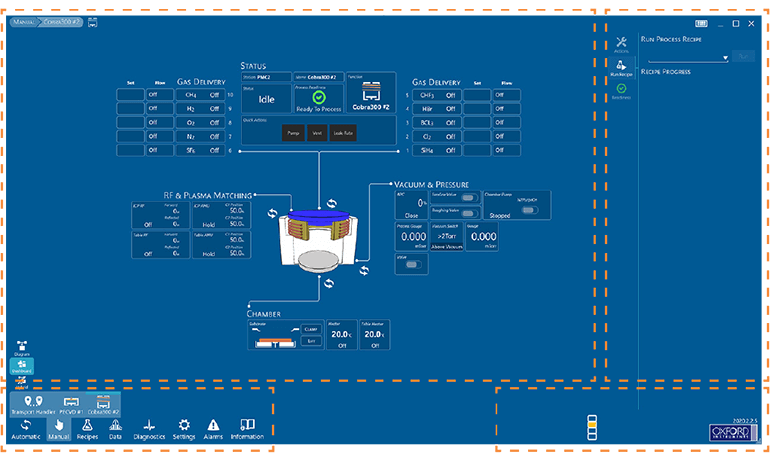

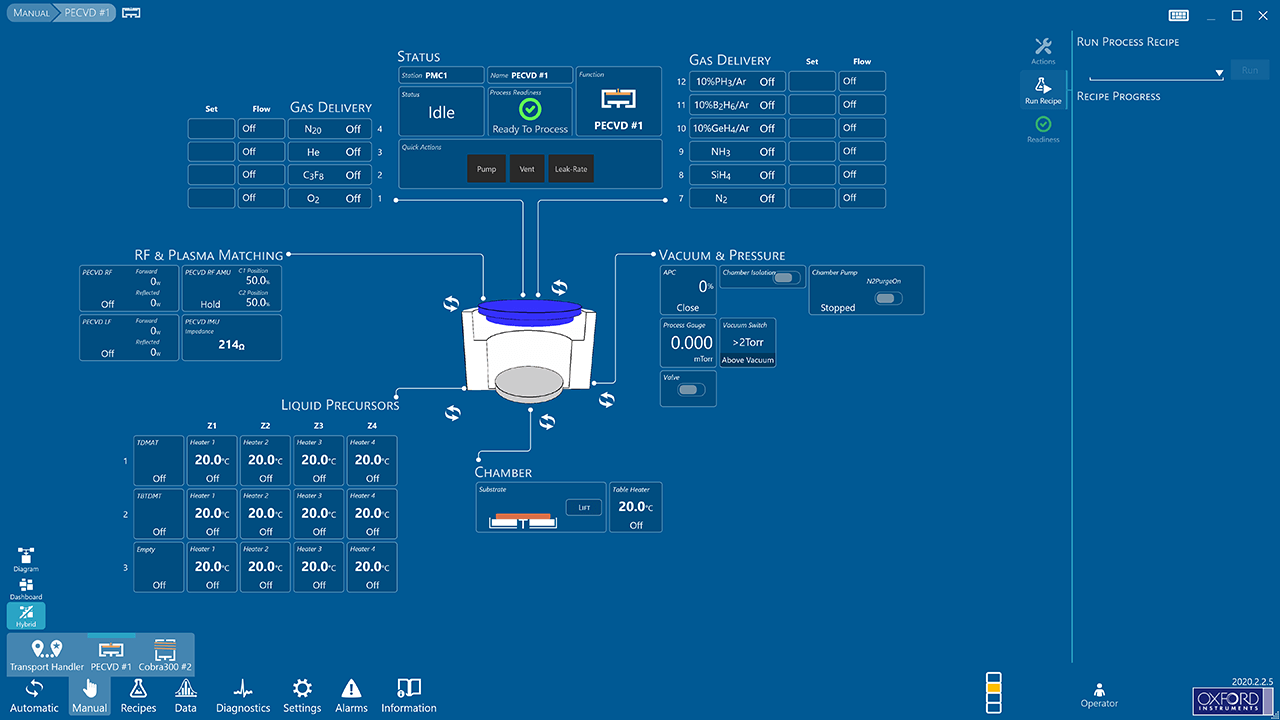

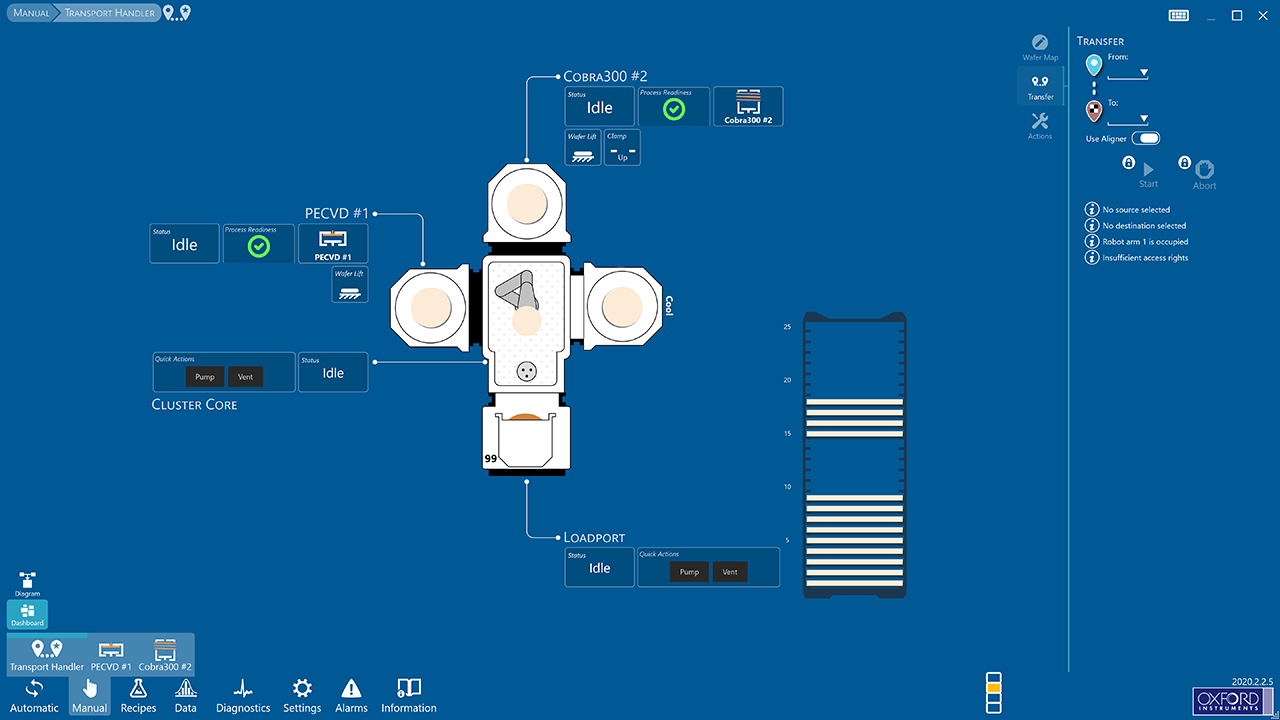

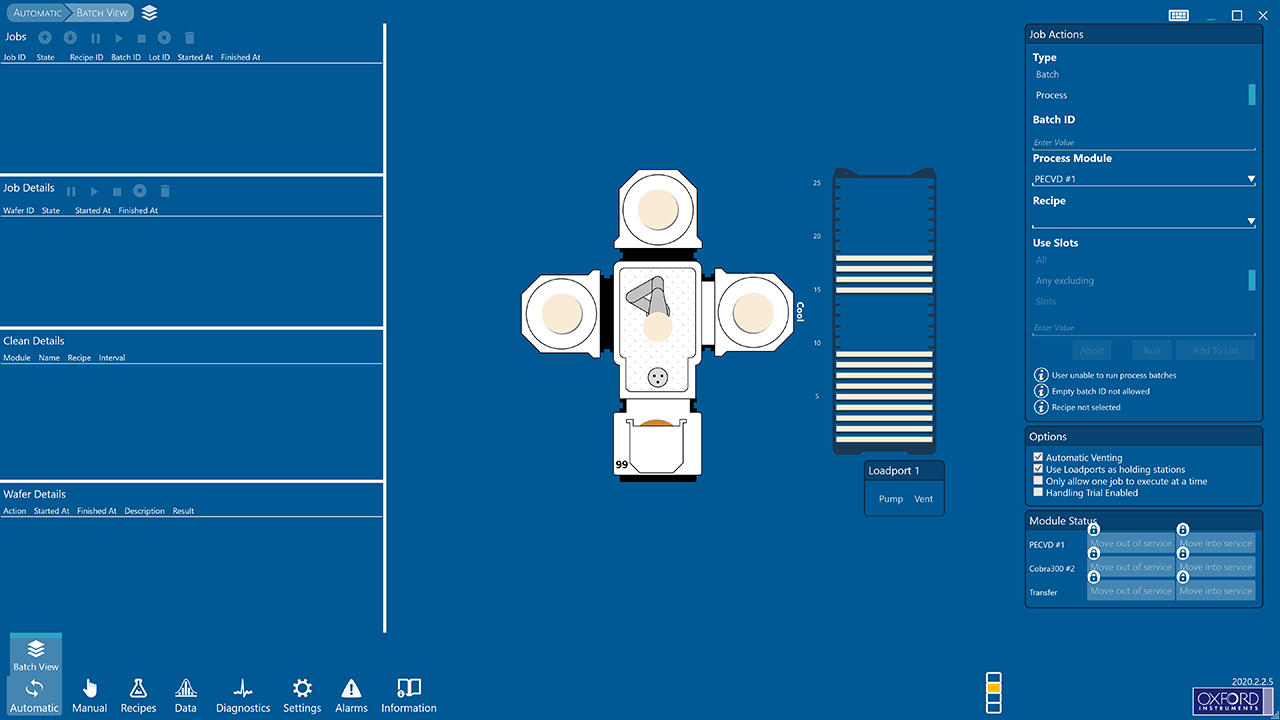

PTIQ Screen Layout. Image Credit: Oxford Instruments Plasma Technology

Operational Readiness and Accuracy

- Visual cues that show the system’s readiness for a procedure assist the user in identifying problems before they become operational, improving process efficiency. They support users of all skill levels and are derived from an internal understanding of best practices.

- Compare results of recipe runs to ensure reliable, repeated processes over time, before/after events, e.g., cleaning and for accelerated process development.

- Millisecond accuracy and 1000-point logging for improved data interrogation.

Flexibility and Reliability

- The operators and engineers can get up and running more quickly because compliance with the SEMI 95 human interface standard gives them a familiar experience.

- Customizable for error-free, multi-user operation in any cleanroom environment.

Image Credit: Oxford Instruments Plasma Technology

Image Credit: Oxford Instruments Plasma Technology

Image Credit: Oxford Instruments Plasma Technology

Features

Recipes

- Recipes include standard checks, such as for leak up rates and MFC fill rate, enabling verification of performance before wafer processing, thus automating interventions for increased efficiency

- Recipes in editable format as process data sheets for error-free and ease of use

- Recipes in private mode for increased security in multi-user environments

- Runs are linked to specific recipe versions for improved traceability

- Tolerance values can now be defined per step, enabling more refined control over the user’s process

Permissions and Scheduling

- Device operation linked to user accounts for secure use

- Configuration options (e.g., pressure units, batch options) linked to user accounts to fine-tune the user experience for increased productivity

- For enhanced productivity, the robust scheduling allows for overlapping chamber operation with wafer transfers (including wafer lift, electrostatic clamping, and wafer preheating)

Software Options

SECS/GEM Factory Host Connection

A software component that links Oxford equipment to a factory host controller through a SECS/GEM interface for use in an automated semiconductor fabrication facility.

AnalytIQs

The purpose of PTIQ AnalytIQs is to increase system uptime while enabling better comprehension and interpretation of process recorded data through statistical data analysis. For the tracking and analysis of all system metrics, they further enhance the PTIQ LogViewer.

On the Roadmap

AnalytIQs Pro

A high-end module for measuring, analyzing, and reporting on the data gathered during processing.

DiagnostIQs

A set of engineer analysis tools are necessary for self-maintained systems and troubleshooting since they delve deep into the electronics that operate the machinery. The customer support engineers at Oxford Instruments have access to the same tools.

PTIQ Backup

This premium module is in charge of routinely backing up the recipe, configuration, and process run data to a remote computer.

This can be done for reference purposes or to transform the data in preparation for necessary external processing.

Upgrading from PCx

Image Credit: Oxford Instruments Plasma Technology

There are numerous upgrade methods available for those who want to update their PC2000 or PC4500 operating system to PTIQ. Users will immediately be registered in the Oxford Instruments Software Assurance Agreement when the update is complete.

Users can update their whole site for a discounted price with site-wide PTIQ Upgrade plans, ensuring continuity of software support moving forward.

Debugging in PTIQ

There have been reports of bugs being found in the PTIQ control software. All PTIQ versions up to and including 2021.13.02 are impacted by the problem. Most customers will not face this problem since it only affects a very particular kind of recipe editing (using sub-steps within a recipe step).