Wood-plastic composites and natural-fibre-reinforced composites have been used in construction since the 1990s, replacing materials such as wood planks, lumber, and metals. In recent studies, carbon nanotubes and graphene have been explored to improve their performance as well as facilitate their potential use in wider engineering fields.

Study: Enriching WPCs and NFPCs with Carbon Nanotubes and Graphene. Image Credit: fotoknips/Shutterstock.com

New research published in Polymers has investigated this area of engineering and materials research.

Wood-Plastic Composites

Wood-plastic composites are composed of 50% wood flour by weight and thermoplastic polymers such as polyethylene, polypropylene, and polyvinyl chloride. Additionally, they contain small amounts of additives, for instance coupling agents and dyes. The wood in the composite material has high strength, whilst the polymers possess hydrophobic properties. Commonly used in construction, they can be designed for specific tasks by tailoring their performance characteristics.

Advantages of wood-plastic composites include a long service lifetime, easy maintenance, and enhanced durability. Due to the large polymer content by weight, they can be easily moulded into specific, complex shapes, and they can be further shaped with common lumber-shaping tools. Moreover, the wood content and the potential for using recycled polymers confer advantages for sustainability, in line with the concept of the circular economy.

However, wood-polymer composites possess some drawbacks. Their mechanical properties can be worse than some materials such as raw wood due to their predetermination by the large weight share of the polymer matrix, which gives the composites mechanical properties closer to those of the base polymers. Additionally, they can be susceptible to environmental degradation such as moisture, temperature, light, mechanical stress, and micro-organisms. This can affect the mechanical strength of composites as well as their aesthetic properties.

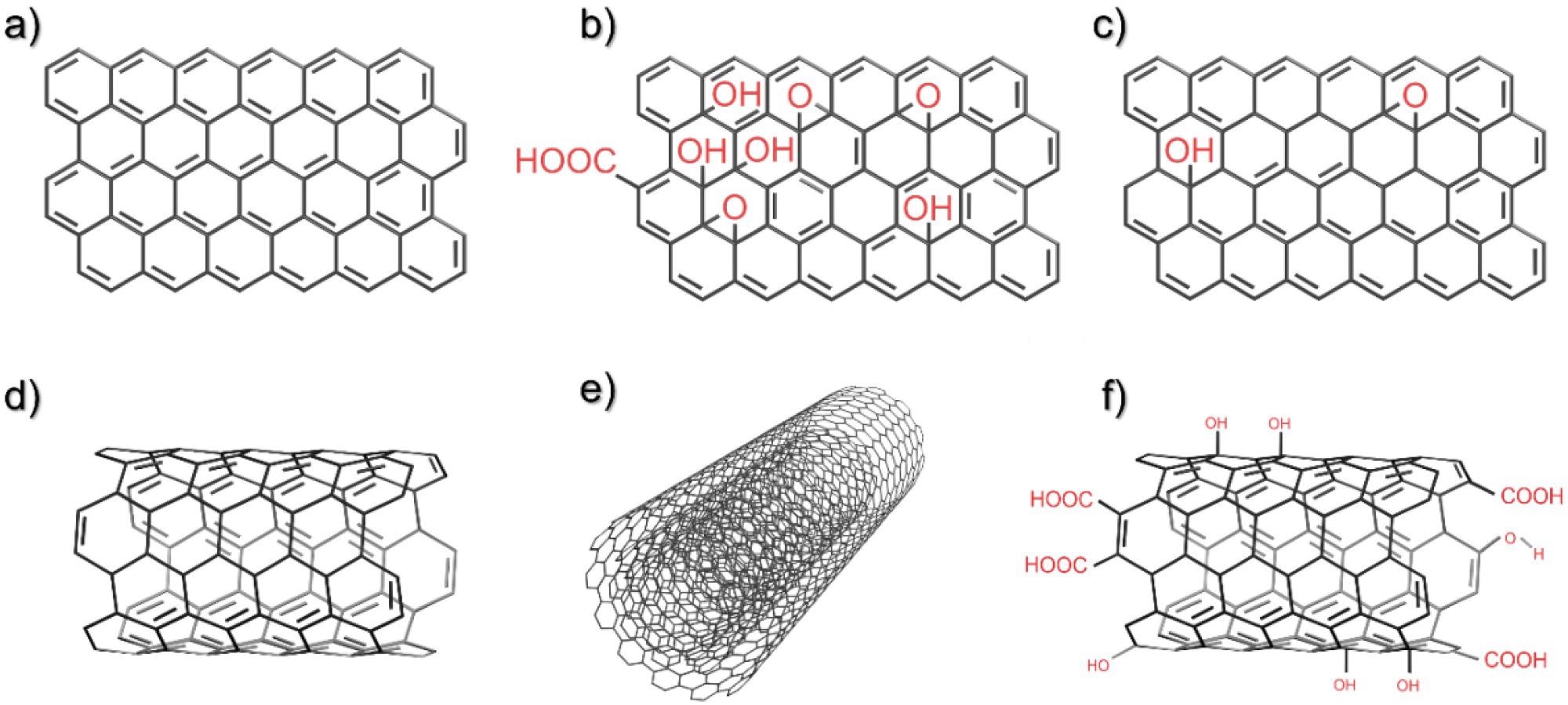

Structure of (a) graphene, (b) graphene oxide, (c) reduced graphene oxide, (d) single-walled carbon nanotube (e) multiwalled carbon nanotube, and (f) functionalised carbon nanotube. Annotation indicates where the structure is not pure carbon. Image Credit: Łukawski, D et al., Polymers

Natural Fiber-Reinforce Composites

Despite the drawbacks to wood-polymer composites, their advantages and already widespread use favours research development. Recent studies have extended to the manufacture of natural fibre-reinforced composites, which are composed of other cellulose-rich materials from sources such as plant shells, bamboo, and milled straw which function as fillers.

Due to the recent expansion of research interest into natural fibre-reinforced composites, wood-polymer concretes are sometimes classified as a subgroup. These composites have not been as widely applied as wood-polymer composites, as currently their performance has been discovered to be less than satisfactory. However, recent studies in the field have been encouraging.

Improving the Performance of Composites with Carbon Nanomaterials

Recent studies have focused on improving the mechanical properties, range of applications, utilizing novel matrix types, and developing new manufacturing processes. One notable area of study is the use of carbon nanomaterials such as carbon nanotubes and graphene to enrich these composite materials.

The atomic structure of carbon nanotubes and graphene, which are nano-allotropes of pure carbon, imparts these nanomaterials with superior mechanical strength, stiffness, and thermal and electrical conductivity. Additionally, these nanomaterials are superhydrophobic, lightweight, and resistant to harsh chemicals. Moreover, they are environmentally friendly as they can be produced from CO2 and methane, which are both potent greenhouse gases.

In fact, the first major commercial application of graphene and carbon nanotubes was in polymer composites. Since their discovery, they have been used in composites for products such as sensors, electromagnetic shielding, supercapacitors, and lightweight and strong construction materials. Both of these carbon nanomaterials enhance properties such as thermal stability and mechanical properties, as well as reduce flammability and introduce thermal and electrical conductivity into materials, and so forth.

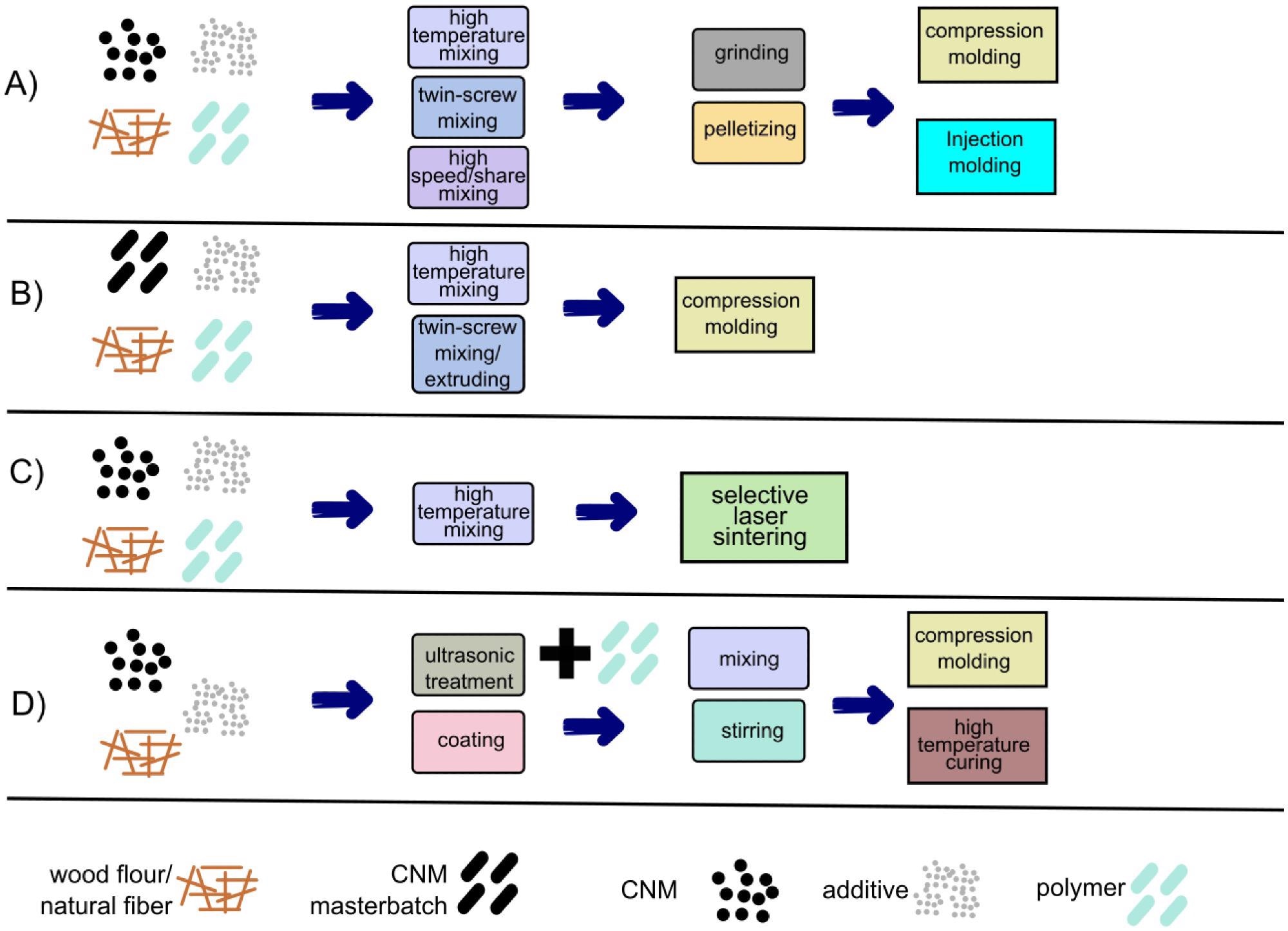

The scheme of various processes used when producing CNM-reinforced WPC. (A) compression/injection moulding with CNM powder, (B) compression moulding with CNM masterbatch, (C) selective laser sintering, (D) compression moulding/high temperature curing with wood flour coated with CNM suspension. Image Credit: Łukawski, D et al., Polymers

The Research

The new research published online in Polymers has provided a comprehensive literature review on carbon nanomaterial-enriched wood-polymer and natural fibre-reinforced composites. The authors have explored the ways that carbon nanomaterials can potentially improve the performance of composite materials, as well as analyzing factors that may influence their properties.

Properties that have been studied to date by researchers are mechanical properties, thermal stability, flammability, photostability, water absorption and swelling thickness, foaming efficiency, thermal properties, and electrical properties. These properties have been explored in-depth in the literature review presented in the current study.

Additionally, the authors have presented examples of novel and innovative applications made possible by the incorporation of carbon nanotubes and graphene as filler materials in hybrid composites.

Rajan et al. have proposed their use in electronic packaging and antistatic materials due to the composite’s increased electrical conductivity. Chen et al. have studied their use as electromagnetic shielding. Lu et al. have proposed creating solar thermal energy storage devices using graphene-oxide enriched wood-polymer composites.

Furthermore, the authors have proposed the use of carbon nanotube-enriched wood-polymer composites as sensors for bending, temperature, and water, though they have stated that to their knowledge these materials have not been evaluated for these applications.

Finally, the study has identified practical considerations such as cost, listed key challenges in the area, and identified future research directions. Current research indicates that these materials can be cost-effective, facilitating their commercial uptake. However, there needs to be further research into controlling their properties if they are to be viable for widespread commercial use.

Further Reading

Łukawski, D et al. (2022) Enriching WPCs and NFPCs with Carbon Nanotubes and Graphene [online] Polymers 14(4) 745 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/4/745

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.