De Beers, the world's largest diamond producer, is using a Zwick compression testing machine to analyze how diamonds break during mining. While diamond is the hardest naturally occurring material, it is very brittle. This is a problem during mining, as comminution, separation and transport processes can all damage this valuable product.

When using software packages to simulate diamond breakage during mining processes, an important characteristic is the breakage function. This distribution gives a measure of how easily a diamond is damaged and has, until now, not been fully quantified.

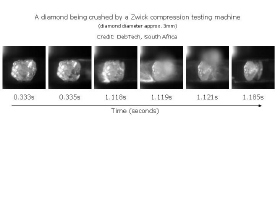

Using a Zwick compression testing machine, researchers at South African company DebTech, a research and development arm of the world's largest diamond producer De Beers, have for the first time been able to experimentally measure the breakage function of a diamond.

"Being able to measure the breakage function gives us a lot more confidence in our simulations," says Dr Garry Morrison, senior research scientist at DebTech. "The Zwick compression testing machine also gives us a way of relating simulated breakage to actual diamond breakage, which is a very useful tool."

As well as crushing diamonds, the Zwick machine is also used to fracture ceramic cylinders, which are used by diamond mines to periodically assess the effectiveness of its mining processes. These ceramic cylinders are put through the mining process and their fragments are collected and analysed at the other end.

"Diamond mining is a trade off between doing things as quickly, and therefore as severely, as possible and not damaging the product," says Morrison. "The Zwick machine is helping us to better understand the effects our processes have on our product."

Morrison uses a Zwick Z030 Allround-Line Table-Top Machine for his experiments. This is equipped with a 30 kN load cell and features Zwick's testXpert software, which is easy to use and modular in design. Intelligent assistants help the customer to set up or change test procedures and it is compatible with all commercially available PCs and laptops without the need for an additional connection card. It adopts industry-specific terminology and can easily export data to a company's central laboratory database. The software also enables frame synchronization of video recordings and features a Laboratory Information Management System (LIMS). This is a powerful database that can be used to administer test results spanning a number of test series. Its graphical sequence editor enables the customer to design customized test procedures by combining test events, parameters and results. It analyzes the test procedure and can filter out errors in the early stages without destroying a single specimen.

The tests are run at 5mm/min load rate and each sequence is filmed with a high-speed video camera. Loads can vary from tens of Newtons to thousands of Newtons and each diamond behaves differently depending on its shape, its flaws and inclusions. Some break into two or three larger fragments and others fracture into vast numbers of tiny fragments. "We can typically test 30 diamonds a day using the Zwick," says Morrison. "The time-consuming part is the characterization of the size and shape of all the fragments after each test." An analysis of the size and shape distributions of the broken fragments gives the breakage function.

"The fact that I can measure loads at a resolution of less than 1 N is useful," says Morrison. "Another plus is the ease of set-up. This is important, since in both our applications we attach our own custom anvils. The software enables me to do this very easily thus allowing us to change between configurations quickly."