Feb 4 2009

Seeking greater design freedom and greater reflecting area, North American auto makers are adopting automotive headlamp technologies that demand higher temperature resistance and durability in automotive lighting parts. Two DuPont engineering resins have been adopted for new lamp socket wire harness designs that are components of these systems. These headlamp technologies already are predominant in European and Japanese vehicles.

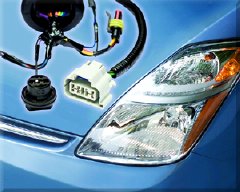

Headlamp wire harness from Empire Electronics that uses the T20 lamp socket and connector molded from DuPont engineering polymers, which meet rigorous performance requirements.

Headlamp wire harness from Empire Electronics that uses the T20 lamp socket and connector molded from DuPont engineering polymers, which meet rigorous performance requirements.

DuPont™ Zytel® HTN is being used by Empire Electronics, a leading systems supplier, for T20 sockets that deliver the same power output as conventional sockets with a smaller footprint. For new in-line connectors, Empire selected DuPont™ Crastin® PBT thermoplastic polyester resin for hydrolysis resistance and dimensional stability.

“DuPont gave us great applications support in our development of two key components,” said Empire’s Director of New Programs Robert Gray. “Zytel® HTN allows us to meet stringent temperature requirements and connectors made with Crastin® comply with demanding United States Council for Automotive Research (USCAR) requirements.”

According to Karla Butler, DuPont Automotive Americas marketing and development director, DuPont’s strong capabilities in applications development make DuPont a first choice of many companies developing new automotive components. “These are highly technical applications requiring deep expertise. Through DuPont’s global network, we can work seamlessly to support companies supplying original equipment manufacturers no matter where in the world they wish to do their developments,” Butler said.