Jul 30 2009

Sensor Products Inc. presents Pressurex, a thin Mylar-based sensor film that maps and measures the amount of interfacial stress exerted on honeycomb cores, composite lay-ups and bonded surfaces within composite structures. By using Pressurex to see how surface stresses are distributed, an engineer can observe inconsistencies and misregistration in composite parts and thereby greatly reduce the yield defect rate.

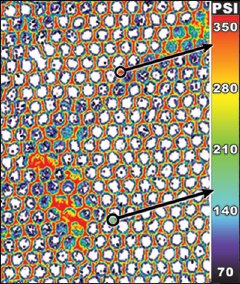

Color Variations Expose Inconsistencies In Composite Layup Contact Pressure (Courtesy Sensor Products Inc.)

Color Variations Expose Inconsistencies In Composite Layup Contact Pressure (Courtesy Sensor Products Inc.)

Other applications for Pressurex include determination of press planarity in lamination processes, monitoring of vacuum bagging pressures, confirmation of pressure uniformity on wound filaments parts, and calibration of tools and equipment.

Pressurex is available in sheets or rolls. When placed between contacting or mating surfaces, the film instantaneously and permanently changes color. This color change is a direct result of the amount of pressure applied. Comparison of color variations to a color correlation chart (conceptually similar to interpreting Litmus paper) can help determine precise pressure magnitude. Pressurex can detect pressures from 2 to 43,200 PSI (.14 to 3,037 kg/cm2). Depending on the requirements of the project, additional graphical and statistical data can be retrieved from the film through Topaq, an optical analysis system that can be bought or leased from Sensor Products Inc. or used by their staff.

In the aerospace industry, Pressurex has been used to determine the exact amount of pressure causing cracks in the inner spars of a helicopter's main rotor blade. A large sheet of Pressurex was inserted into the bonding tool, bagged up, and pressurized in the autoclave. When the film was removed, the exact amount of pressure causing the crack was determined.