Solar energy is presently experiencing an enormous upsurge in interest, adding emphasis to the need to optimize efficiency and cost-effectiveness. Materials testing has a vital role to play here, with a multitude of testing options already available to the solar market from leading testing system manufacturer Zwick.

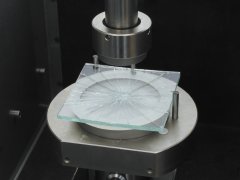

Broken glass sheet following punch test.

Broken glass sheet following punch test.

Roof-mounted photovoltaic units must be able to withstand the effects of extreme weather. Their life expectancy of 20 to 40 years places heavy demands on wafers, solar cells, modules and so on. Many different methods are used to test a wide variety of materials and components, although there are few officially recognized standards, with manufacturers operating on an individual basis. The main emphasis is on testing solar module segments and components, together with module mountings and inverter electronics.

Typical solar industry tests include:

- 45° compression shear test on adhered glass sheets

- 90° or 180 ° peel test (peeling film from glass sheet)

- tensile test on films to ISO 527

- double ring test on glass, similar to DIN EN 1288-5

- tear test on electrical connections

- tensile test on electrical cables and cable connections

- tensile, compression and flexure tests on mounting systems for attaching modules.

It is essential that clamping fixtures and test devices are optimally matched to the components to be tested. The testing machine manufacturer's experience is invaluable in providing manufacturers of photovoltaic units with access to advice regarding specimen production or the correct test fixtures, testing machines and software.

Complete solutions are already available from Zwick. Special retaining and support systems, including the customer's own, can be integrated into the testing machine to enable tensile, compression and cyclic tests to the customer's requirements. Tests are performed and evaluated by intelligent testXpert II testing software, a product reflecting Zwick's long-standing expert knowledge of fields such as data links (import/export) to other applications, multimedia testing and full documentation of a materials test, or simple test series management.

Testing is an essential element in ensuring that photovoltaic units actually deliver their calculated performance; their long service life makes it an extremely worthwhile investment.