Work undertaken in Japan and described in a new application note on the Malvern Panalytical website, examines the influence of particle shape on the characteristics of coating film for battery electrodes. Using the Sysmex Flow Particle Image Analyzer FPIA-3000, available from Malvern Panalytical, researchers at Hokkaido University looked at both the size and shape of graphite particles in coating films produced by different methods.

They concluded that examining particle shape as well as size allows a better understanding of the packing structure of the final coating film and hence its permeability and recharging-discharging characteristics.

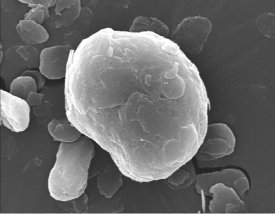

The raw carbon material used to produce these coatings is usually in the form of flakes, which are then processed (conglobulated) into more spherical particles. A number of coating films were produced using particles of different shapes as determined with the Sysmex FPIA-3000, and their packing structure was assessed by electron microscopy. Subsequent examination of permeability characteristics demonstrated that the more spherical material permits better fluid permeation and consequently helps improve high-rate discharging performance of a secondary battery.

The Sysmex FPIA-3000 is an easy-to-use automated instrument that is well suited to analyzing fine particles, capturing images of hundreds of thousands of particles as they pass in front of a camera. Results in terms of individual particle size and shape, and associated distributions, are produced. Size/shape correlation is straightforward.

Coating films and porous material obtained from fine particles, the size of a few microns, are used in many different industrial processes, including for electromagnetic materials, drugs and pharmaceutical tablets as well as in ceramics. Achieving the optimal adjustment of particle characteristics for a coating film is important towards improved functionality in many products and the Sysmex FPIA-3000 is useful for both research and quality management applications.