Jul 6 2010

Raydiance, Inc., the world’s leading developer of ultrafast laser technology, announced today that it has demonstrated the ability to machine precise, micron-resolution features in gold and platinum, two of the more difficult-to-process materials used in advanced medical devices.

Raydiance engineers achieved the results using the company’s Smart Light(TM) 50 femtosecond pulse laser integrated into a Rofin StarCut Tube workstation.

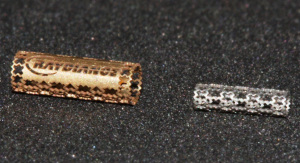

At left is an 18 k gold stent with outer diameter of 2.08 mm and wall thickness of 140 microns.

At left is an 18 k gold stent with outer diameter of 2.08 mm and wall thickness of 140 microns.

Due to their radiopacity, resistance to corrosion, and high electrical conductivity, gold and platinum, in particular, are showing increasing utility in medical devices, including heart rhythm leads, cardiovascular stents, and guide wires used for cardiovascular procedures. In the latter two applications, the precious metals are used as X-ray markers to better enable surgeons to see devices during procedures.

“Medical device manufacturers have a very difficult time machining precise features in these ductile noble metals,” said Scott Davison, president of Raydiance. “Traditional tools—mechanical saws, electron discharge machining, and even nanosecond lasers—introduce all kinds of burrs and thermal effects that necessitate costly post-processing. The Raydiance platform provides an efficient, athermal solution to this manufacturing problem.”

Raydiance’s ultrafast laser ablates through non-linear optical breakdown, a process that enables micron-resolution ablation of virtually any material without transferring heat to the part being machined.