A new 75-watt photovoltaic (PV) module designed with DuPont PV5400 Series encapsulant has been commercialized by the Willard and Kelsey (W&K) Solar Group.

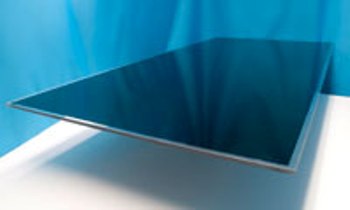

Willard & Kelsey Solar Group’s new frameless WK1-75 module is a laminated glass-glass cadmium-telluride structure using clear DuPont™ PV5400 Series photovoltaic encapsulant.

Willard & Kelsey Solar Group’s new frameless WK1-75 module is a laminated glass-glass cadmium-telluride structure using clear DuPont™ PV5400 Series photovoltaic encapsulant.

The new WK1-75 frameless module uses a cadmium-telluride (CdTe) thin-film layer and it is protected by the application of DuPont PV5400, highly moisture-resistant ionomer-based encapsulant.

Solar manufacturers frequently require an edge seal to stop moisture ingress at the edges of the conventional PV modules. This increases labour and material costs to lessen the inherent moisture susceptibility of standard encapsulants. DuPont PV5400 encapsulant, when deployed in the new PV module, eliminates moisture entry better than other encapsulants. Thus, the material prevents the requirement for edge seals and enables W&K’s modules to achieve durability exceeding the current standards. The damp heat testing reveals that the WK1-75 frameless module survived over 4,000 hrs, which is more than the standard 1,000 hrs for acceptance.

DuPont PV5400 encapsulant is about 5 times stronger and 100 times stiffer than traditional thin film materials. It enhances mechanical strength and deflection resistance of the module. DuPont supplies the encapsulant in rolls with thicknesses ranging from 0.40 to 0.50 mm and they can be used readily as sheets up to 160 cm wide. DuPont has offered assistance to W&K on the ionomer sheet processing methods and testing protocols employed for the new WK1-75 frameless module.