NuSil Technology has launched a new electrically conductive, low outgassing film adhesive that is suitable for space and electronics applications.

CV-2681-12 is a user-friendly, low out gassing film adhesive

CV-2681-12 is a user-friendly, low out gassing film adhesive

The CV-2681-12 adhesive is static-dissipative with controlled volatility and its applications range from tacking down wires to solar mirrors and cells.

The CV-2681-12 is ideal for space uses that need negligible outgassing in sensitive applications, such as satellites. This space-grade material can retain its adhesion property in a wide range of temperatures. Thus, it is a perfect choice for EMI and RFI shielding in space applications as well as for applications where temperature is a major concern. The material's volume resistivity is 125 Wcm and it has about a 0.012" controlled bond line for reliable bond thickness.

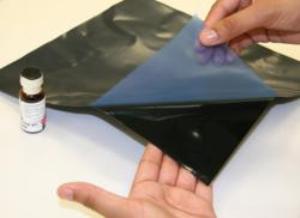

The film adhesive from NuSil Technology is easy-to-use and it needs no mixing or deairing before usage. The CV-2681-12 is a two-part material, which includes HCR sheeting strengthened with a mesh and a catalyst called activator to stimulate the curing process. It is a room temperature vulcanizing (RTV) adhesive and hence, it does not require heat for curing.

Brian Burkitt, Product Director of Engineering Materials, noted that once the activator is applied over the substrate, the adhesive has to be peeled from the backing and glued on the prepared surface. The film adhesive meets or surpasses the ASTM E 595 low outgas specifications that are summarized in the European Space Agency PSS-014-702 and NASA SP-R-0022A.