IBN researchers have used a mixture of copper, gold and platinum nanoparticles and designed a long-lasting and powerful fuel cell material. This breakthrough was recently published in a leading journal, Energy and Environmental Science.

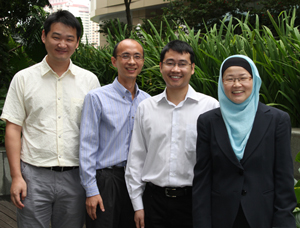

From left to right: Dr Xianfeng Yang, IBN Research Scientist; Dr Xiaojun Chen, IBN Senior Research Scientist; Dr Jinhua Yang, IBN Research Scientist; and Prof Jackie Y. Ying, IBN Executive Director and Senior Group Leader

From left to right: Dr Xianfeng Yang, IBN Research Scientist; Dr Xiaojun Chen, IBN Senior Research Scientist; Dr Jinhua Yang, IBN Research Scientist; and Prof Jackie Y. Ying, IBN Executive Director and Senior Group Leader

Platinum nanoparticles are being currently used as the catalyst since it is the only metal capable of withstanding the acidic conditions inside the cell. However, platinum is expensive and exhibits low stability preventing fuel cells to be widely used.

A research team led by Jackie Y Ying, IBN Executive Director Professor discovered that when the core of the catalyst is replaced with copper and gold alloy and only the outer layer has platinum, the novel hybrid material offers five times more activity and better stability than the commercial platinum catalyst. By optimizing further, it is possible to improve the material’s catalytic properties further.

The novel nanocomposite material of IBN can produce 0.571 A of electric current per milligram of platinum, when compared to 0.109 A per milligram of platinum for commercial platinum catalysts. This is probably the first time a catalyst has improved the activity and stability of the fuel cell reaction with a considerably reduced platinum content.

A gold-copper alloy has been chosen as the core since it has a smaller lattice spacing when compared to the platinum coating on the surface of the nanocrystal. Due to this, a compressive strain is formed in the surface platinum atoms, rendering the platinum more active in the rate-limiting step of oxygen reduction reaction for the fuel cell.