Sep 14 2012

Toronto based Integran Technologies Inc. (Integran) today announced that it had received patent protection (US 8,247,050) for its vacuum tight, pore free, and tough electroplated nanometals for thermoplastic and composite parts.

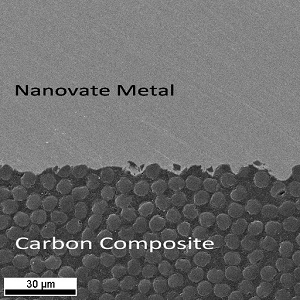

Under development for several years, Integran's electroplated "Nanovate" metals allow customers with thermoplastic parts to not only benefit from the added strength and stiffness these metals bring, but also keep gases and liquids from penetrating the parts.

Designers can now also look at using composites for creating vacuum tight products such as pressure vessels, and hydraulic actuator rods and cylinders with a surface that is as durable as a hardened tool steel. This technology is also an essential part of Integran's programs to make durable, low thermal expansion lay-up molds for aerospace composite manufacturing.

As Jon McCrea, Integran's Research and Development Manager, elaborated, "A porosity-free high strength nanostructured metal, like our series of Nanovate coatings, is ideally suited for customers that require a multifunctional coating that can deliver both a gas/liquid impermeable barrier as well as a surface with high wear resistance and toughness. This is not possible with electroplated metals like chrome coatings, which are microcracked, or HVOF coatings (flame sprayed metals/ceramics) which are intrinsically porous. Think of the nanocrystalline metal structure as a tightly packed array of metal atoms so efficient that it leaves little space for anything to penetrate - this is what is known as a fully dense structure and is quite unique to Nanovate metals created by our process."