This year, BASF is presenting not only its thermosetting materials at "Composites Europe" trade fair being held in Stuttgart from September 17 to 19, 2013, but also its new thermoplastic composites with continuous fiber reinforcement developed specifically for lightweight applications for the automotive industry. In addition, polyurethane technology news for wind turbine applications will be exhibited by BASF in Hall 4, Booth B26.

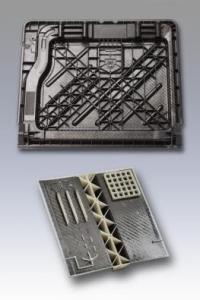

The seatback manufactured by Johnson Controls is one of the first, externally manufactured prototypes resulting from BASF’s new Ultracom™ product and service package. The new materials employed here include Ultralaminate™ and the overmolding compound Ultramid® ZG7 COM. The computer-assisted component design using the universal Ultrasim® simulation tool is also a unit of the three-fold package. The CIFO part (lower figure), made on the new production-scale manufacturing cell at BASF, is a test component for continuous fiber-reinforced composite parts based on laminates/tapes and overmolding compounds. It incorporates over 20 individual functionalities. Photo: BASF - The Chemical Company, 2013

The seatback manufactured by Johnson Controls is one of the first, externally manufactured prototypes resulting from BASF’s new Ultracom™ product and service package. The new materials employed here include Ultralaminate™ and the overmolding compound Ultramid® ZG7 COM. The computer-assisted component design using the universal Ultrasim® simulation tool is also a unit of the three-fold package. The CIFO part (lower figure), made on the new production-scale manufacturing cell at BASF, is a test component for continuous fiber-reinforced composite parts based on laminates/tapes and overmolding compounds. It incorporates over 20 individual functionalities. Photo: BASF - The Chemical Company, 2013

Automotive – new composites concepts

First customer prototype demonstrating the new Ultracom package: Rear seatback from Johnson Controls

Following the introduction of its new Ultracom™ product and service concept in June 2013, BASF is now able to present the first prototype composite part demonstrating this service package at the Composites Europe fair: The seatback developed for automobile rear seats by Johnson Controls Automotive Seating together with BASF is based on Ultralaminate™, one of the new continuous fiber-reinforced thermoplastic woven fabrics that is overmolded with Ultramid® ZG7 COM, a specially formulated, high-impact modified polyamide 6. During development, the extensive simulation know-how of BASF was provided as part of the Ultracom package. Compared to the current metal version, the complex composite part provides weight savings of more than 30 percent.

CIFO part: Material, process and component development

In addition, the new CIFO part, its name being derived from Combination of Inmold-Forming and Overmolding, will be displayed at Composites Europe as well. It was developed by BASF to fully exploit all possibilities of composite part design with Ultracom™ in its new manufacturing cell. The multifunctional test part for investigating continuous fiber-reinforced composite component with regard to volume production consists of a 1.5-mm-thick formed laminate and up to 3-mm-thick molded-on functional elements such as ribs and edges. Using this part, with its approximately 20 individual functionalities, it is possible to demonstrate the characteristics of composite part manufacturing. Special features of the component include sealing the edges, long flow paths, formed holes, a rib array, multiply molded-through elements as well as a ribbed U-profile beam.

RTM epoxy fender prototype

In addition to polyamide, the multi-material Lightweight Composite Team at BASF is also developing continuous fiber-reinforced composite concepts based on polyurethane and epoxy resin systems for structural and semi-structural applications. The company is exhibiting its new Baxxodur® System 2202 epoxy resin, developed specifically for high-pressure RTM (Resin Transfer Molding), in the form of a carbon fiber-reinforced fender demonstrator. The epoxy resin system cures at 120 °C with a demolding time of only 2.5 min, exhibits good mechanical properties and has a wide processing window.

New polyurethane concepts: For wind turbines and more

Pultruded polyurethane part

For the first time at Composites Europe, BASF is exhibiting a pultruded part manufactured from Elastocoat® C6226-100 polyurethane resin. Together with its partner Fiberline Composites A/S in Denmark, BASF developed this resin for production of pultruded rods for secure attachment of the rotor blade root to the nacelle. The continuous pultrusion process permits better alignment of the fibers as well as in-line integration of a metal bushing, so that high and constant product quality is assured. The polyurethane resin ensures improved adhesion to the metal bushing and also to the epoxy infusion resin. The pre-manufactured part allows to forego the classical concept of drilling sideway holes to fix the bushings. It thus makes possible a reduction of both blade root and hub diameter, resulting in substantial material savings.

Composite technology: PU foam sandwich

BASF is also showing a sandwich panel with glass fiber-reinforced laminate based on the Baxxodur epoxy resin system and a foam core made from a new, especially fatigue-resistant version of Elastolit® polyurethane foam. For this, the team at BASF Polyurethanes GmbH in Lemförde modified the properties of the previously rather brittle PU foam for use in the sandwich – a four-point bending test validated the significantly improved dynamic properties and high impact strength. This PU molded foam system allows producing complex geometry foams in a single shot and as such complements the new BASF Kerdyn® PET foam.

Wind turbine rotor cross-section

On display for the first time at Composites Europe: the cross-section of a wind turbine rotor incorporating the wide range of BASF products for rotor blade production. The glass fibers are encapsulated in Baxxodur resin, which is ideal for use in vacuum infusion. The Kerdyn PET structural foam provides good mechanical properties to ensure the required stability of the blade's interior. The outer finish of the rotor cross-section employs the RELEST® gelcoat system and the semi-structural Elastan® polyurethane adhesive also belongs to the BASF product line.