Dow Electronic Materials, a business unit of The Dow Chemical Company, today announced availability of its SOLDERON™ BP TS 6000 Tin-Silver Plating Chemistry for use in lead-free solder bump plating applications. This next-generation formulation features enhanced plating performance, bath stability and ease-of-use, thereby enabling the industry's widest process window with the most robust process flexibility and a competitive cost of ownership (COO).

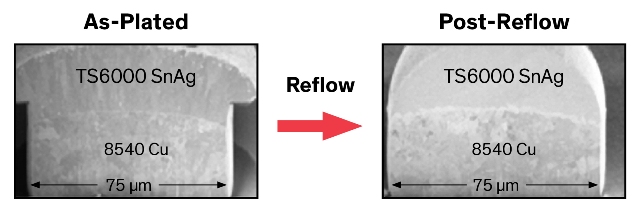

In Cu pillar capping applications, SOLDERON™ BP TS 6000 Tin-Silver forms a smooth,micro-void free interface post reflow

In Cu pillar capping applications, SOLDERON™ BP TS 6000 Tin-Silver forms a smooth,micro-void free interface post reflow

“As flip chip packages become mainstream and the industry continues to move toward 2.5D and 3D packaging technologies, there is a clear market requirement for high-performance lead-free alternatives for plating applications,” said Dr. Robert Kavanagh, global business director, Advanced Packaging Metallization, for Dow Electronic Materials. “Customers need materials optimized for today’s finer bump geometries. This new chemistry achieves significant performance improvements, delivering even faster plating speeds, better uniformity and smoother surface morphology in addition to a smooth, void-free interface when used together with Dow’s and other leading copper (Cu) pillar formulations.”

With a single formulation, SOLDERON BP TS 6000 Tin-Silver (SnAg) is capable of plating speeds ranging from 2 to 9 um/min., which creates a significantly wider operating window when compared with other solutions in the marketplace. The tunable nature of the Ag composition in this formulation makes it suitable for a number of applications and eliminates the need to change the chemistry to address different processing requirements. The new chemistry has proven to be robust enough for both bumping and capping of a wide range of patterned wafers and it is not restricted for use with specific photoresists. It exhibits with-in die (WID) uniformity after reflow of <5% over a wide range of wafer types, which demonstrates its suitability for high-volume manufacturing. Additionally, it is macro- and micro-void free after reflow for improved yields and reliability.

“One of the most compelling strengths of SOLDERON BP TS 6000 Tin-Silver is the product’s enormous flexibility, which allows it to perform exceptionally well in a variety of applications from in-via and mushroom bumping to Cu and micro-Cu pillar capping,” added Kavanagh.

SOLDERON BP TS 6000 Tin-Silver plating bath has proven to be both electrolytically and thermally stable, which contributes to the chemistry's competitive COO. Offering an electrolytic bathlife of >100 Ah/L and a ≥6-month pot life, it is compatible with in-line metrology processes, for superior ease-of-use.

Samples are currently available and in beta testing withmultiple customers.