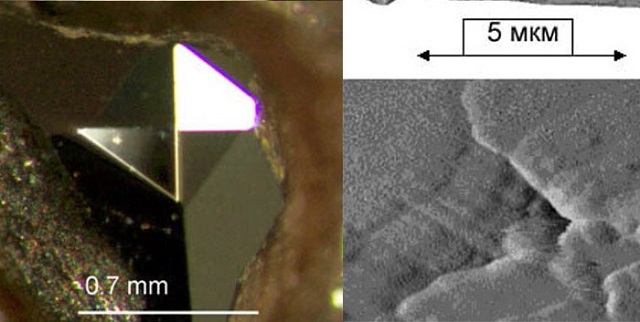

Photo of a Vickers indenter made of ultrahard fullerite. Courtesy of MikhailPopov

Photo of a Vickers indenter made of ultrahard fullerite. Courtesy of MikhailPopov

A collaborative team of researchers have discovered a novel method for synthesis of ultrahard fullerite material. This material is a polymer made up of fullerenes, which are spherical molecules composed of carbon atoms.

The team from Moscow Institute of Physics and Technology (MIPT), the Technological Institute for Superhard and Novel Carbon Materials (FSBI TISNCM), the MSU and the MISiS have collaborated in this study which has been published in the Carbon journal.

Ultrahard fullerite has hardness in the range from 150-300GPa, while natural diamonds possess hardness of around 150GPa. Ultrahard materials are harder than diamond. Materials that have hardness greater than boron nitride but less than that of diamond are considered as superhard materials. Boron nitride is nearly three times as hard as corundum material.

Fullerites are polymers that are composed of fullerenes, which are spherical carbon molecules having 60 atoms. The synthesis of fullerene was awarded a Nobel Prize over 20 years ago. The hardness of fullerite depends on the interconnection of the carbon spheres within the material. The C 60 molecules in the ultrahard fullerite developed by FSBI TISNCM are interconnected in all directions by covalent bonds, and hence the material is considered as a 3D polymer.

Ultrahard materials have significant uses in processing of metals and other materials, as harder tools have a longer life. However, the methods for production of this material on an industrial scale have not yet been developed. Sythesis of fullerite requires a high pressure of 13 GPa and a high temperature of 1100K, which has until now prevented the development of a process for industrial scale production.

schematic representation of a fullerene molecule, C 60

This new method allowed the researchers to add carbon disulfide (CS2) which accelerated the synthesis of fullerite and allowed the process to be performed at a lower pressure of 8GPa and at room temperature.

The discovery described in this article (the catalytic synthesis of ultrahard fullerite) will create a new research area in materials science because it substantially reduces the pressure required for synthesis and allows for manufacturing the material and its derivatives on an industrial scale.

Mikhail Popov, the leading author of the research and the head of the laboratory of functional nanomaterials at FSBI TISNCM.

References