Nov 11 2014

An international research team from Hong Kong University of Science and Technology and North Carolina State University has discovered that high-efficient organic solar cells can be produced cost-effectively and in large quantities by applying temperature-dependent aggregation in semi-conducting polymers.

Temperature-controlled aggregation in a family of new semi-conducting polymers appears to be the key to creating highly efficient organic solar cells that can be mass produced more cheaply.

Temperature-controlled aggregation in a family of new semi-conducting polymers appears to be the key to creating highly efficient organic solar cells that can be mass produced more cheaply.

Polymer solar cells are typically produced by adding a solvent to fullerenes and polymers until the mixture changes to a liquid form, and this liquid is then spread onto a surface. When the solvent evaporates, the layer solidifies and the donor material turns into small, highly organized clumps.

The study revealed that aggregation and size scale within polymer devices depend on temperature. It also showed that it is possible to achieve record efficiencies of 10.8% by replacing fullerenes. These efficiencies can also be obtained in thick film devices. At present, highly efficient organic solar cells are produced by utilizing one of the two different fullerenes.

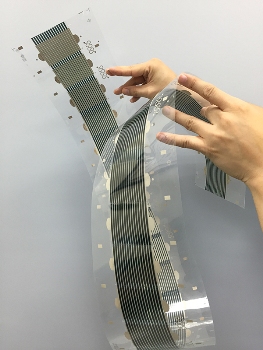

“Once we saw how temperature affected the aggregation and morphology of these solar cells, it allowed the chemists more freedom to play with different chemical compositions in the active layer,” said NC State physicist Harald. “Yan’s team demonstrated 10 percent efficiency with 10 different mixtures, and in thicker films. So these solar cells could be compatible with existing methods of mass production, like slot die casting and roll-to-roll processing similar to newspaper printing, rather than the more expensive production methods currently in use that are required for thickness control".

The latest findings make it possible to explore different types of chemical mixtures, such as fullerenes and polymer blends. This would not only improve the efficiency of solar cells, but would reduce manufacturing costs and lead to an alternative source of energy that is commercially viable.

This study has been published in Nature Communications.