Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, report on the µXCT in situ testing being carried out in the School of Engineering at the University of Portsmouth.

The Deben CT5000 tensile system mounted in a Nikon CT X-Ray Inspection System.

The Deben CT5000 tensile system mounted in a Nikon CT X-Ray Inspection System.

Professor Jie Tong leads the Mechanical Behaviour of Materials group at the University of Portsmouth, where she directs a number of research projects in the areas of mechanics of materials and biomechanics, focusing on deformation, fatigue and fracture behaviour of engineering and biological materials and systems.

There are essentially two main questions they try to answer: how materials and components respond to complex loading conditions; and how micro-structural properties dictate global material or structural responses. The group has collaborations with industrial partners on fatigue and fracture of aero-engine materials; and with NHS hospitals on biomechanical behaviour of scaffolds.

To better understand how materials behave micro-structurally when loaded in situ, they use the CT5000 5kN in situ loading stage from Deben in conjunction with a µXCT system (Nikon Metrology CT X-Ray Inspection System, X-Tek Systems Ltd). Professor Tong describes the work:

“We first used the loading stage to examine how a biomaterial (scaffold) behaves under compression and its failure modes. We also used it to examine a bone-cement interface under cyclic compression and tracked the damage evolution. We used digital volume correlation (DVC) to map full-field strains post-testing. These are cutting edge applications and have been published in high impact journals [1-3]. Looking ahead, we intend to take the loading stage to synchrotron sources to do more in situ testing, if we are successful in our application for beam time.”

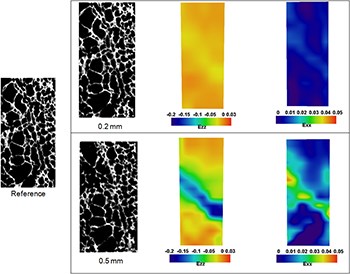

One example is illustrated here [1]. The figure shows the local strains (right) in a 2D section of a scaffold, computed using CT images (left) from the reference and at compressive displacements of 0.2mm and 0.5mm. The sample was compressed along the loading direction. Localised deformation in Ezz along a 45° direction is evident at 0.5mm displacement.

In association with the major manufacturers of µXCT systems, Deben offers an integrated testing solution for µXCT applications. Using in situ testing with µXCT and DVC provides a clear visual and quantitative interpretation of how the properties of materials and composites change under different loading conditions.

The compact design of these testing stages allow them to be used with the smallest, high resolution micro CT systems providing a range of tensile, compression and torsion stages with forces up to 25kN and resolutions down to 25mN. Systems are controlled from the comprehensive MICROTEST tensile stage control software giving a wide range of control functions and a live display of load against extension.

This “live” feature is particularly important in the work of Professor Tong as the standard mechanical testing is limited to global mechanical responses only and micro structural damage can only be examined post mortem.

To obtain full details of the Deben applications and product portfolio, please visit www.deben.co.uk.

References

- K. Madi, G. Tozzi, Q.H. Zhang, J. Tong, D. Hollis, F. Hild. Computation of displacement fields in a scaffold implant using Digital Volume Correlation and Finite Element analysis, Medical Engineering and Physics, 2013: 35(9):1298-312.

- G Tozzi, Q-H Zhang, J Tong. 3D real-time micromechanical compressive behaviour of bone-cement interface: experimental and finite element studies, J Biomech, 2012:45(2):356-363.

- G Tozzi, QH Zhang, J Tong, Micro-damage Assessment of Bone-Cement Interfaces under Monotonic and Cyclic Compression, J Biomech. 2014: 47: 3466-3474.

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk. The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.